A non-contact liquid filling device

A non-contact filling device technology, which is applied in the direction of liquid materials, packaging, packaging protection, etc., can solve the problems of inability to accurately control the liquid level height, achieve the effect of accurately controlling the filling liquid level height and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

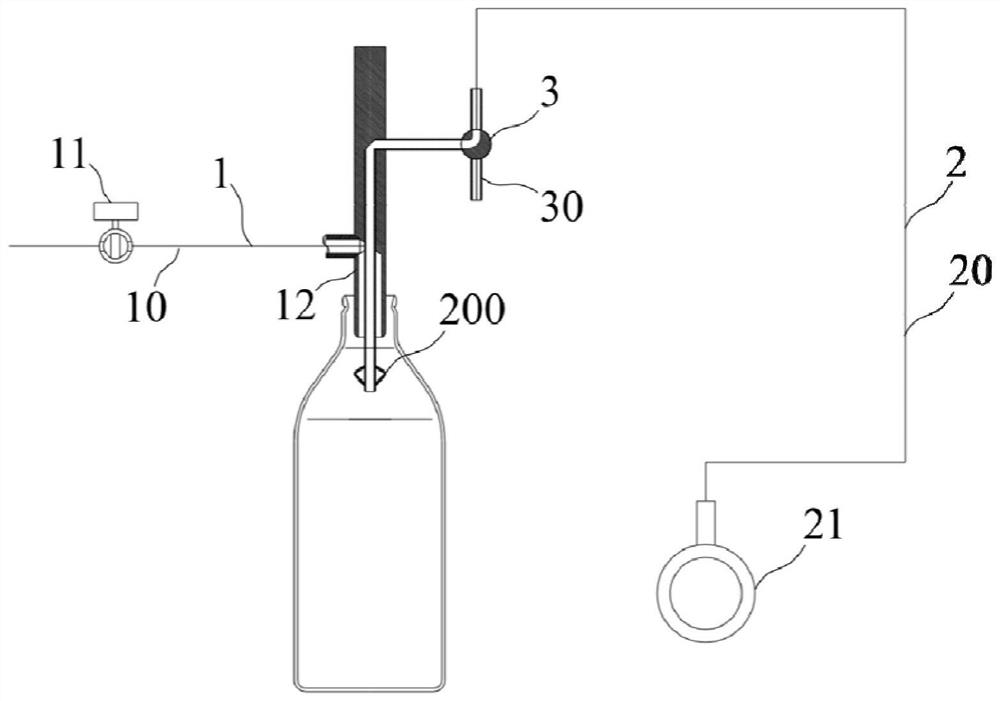

[0060] like figure 1 As shown, the non-contact liquid filling device of this embodiment includes,

[0061] Filling unit 1, which is used to fill liquid materials into containers;

[0062] The detection and control unit 2 is used to detect the height of the liquid material in the container to be filled, and to control the start and stop of the filling unit 1;

[0063] The detection and control unit 2 includes a measuring catheter 20 and a pressure sensor 21;

[0064] One end of the measuring conduit 20 extends into the container to be filled, and the other end is connected to the pressure sensor 21;

[0065] The pressure sensor 21 detects the pressure change in the measuring conduit 20 and is connected with the filling unit 1 to control the start and stop of the filling unit 1 .

[0066] In the prior art, the filling device cannot effectively control the liquid level in the same production line to be consistent. The reason is that in addition to the defects of the filling va...

Embodiment 2

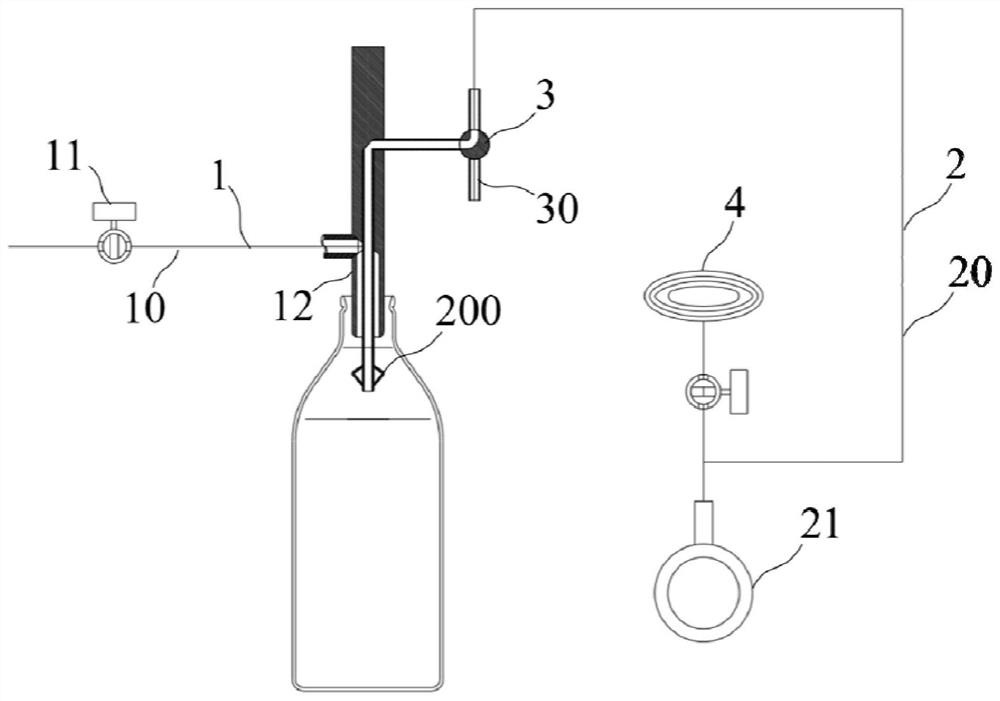

[0072] like figure 1 As shown, the non-contact liquid filling device of this embodiment is further improved on the basis of Embodiment 1, and further includes a three-way valve 3, and two of the flow channel ports of the three-way valve 3 are connected to the measuring conduit 20 Among them, another flow channel port communicates with the liquid suction pipe 30;

[0073] The liquid suction pipe 30 is used to extract liquid materials.

[0074] The three-way valve 3 of this embodiment is arranged on the measuring conduit 20 outside the container, and the three-way valve 3 is divided into three paths, two of which are connected to the measuring conduit 20, and one of which is connected to the suction pipe 30. When filling liquid materials, the three-way The valve 3 connects the two paths connected to the measuring conduit 20 so that the pressure sensor 21 can effectively detect the pressure change in the measuring conduit 20. After the filling stops, the three-way valve 3 is swi...

Embodiment 3

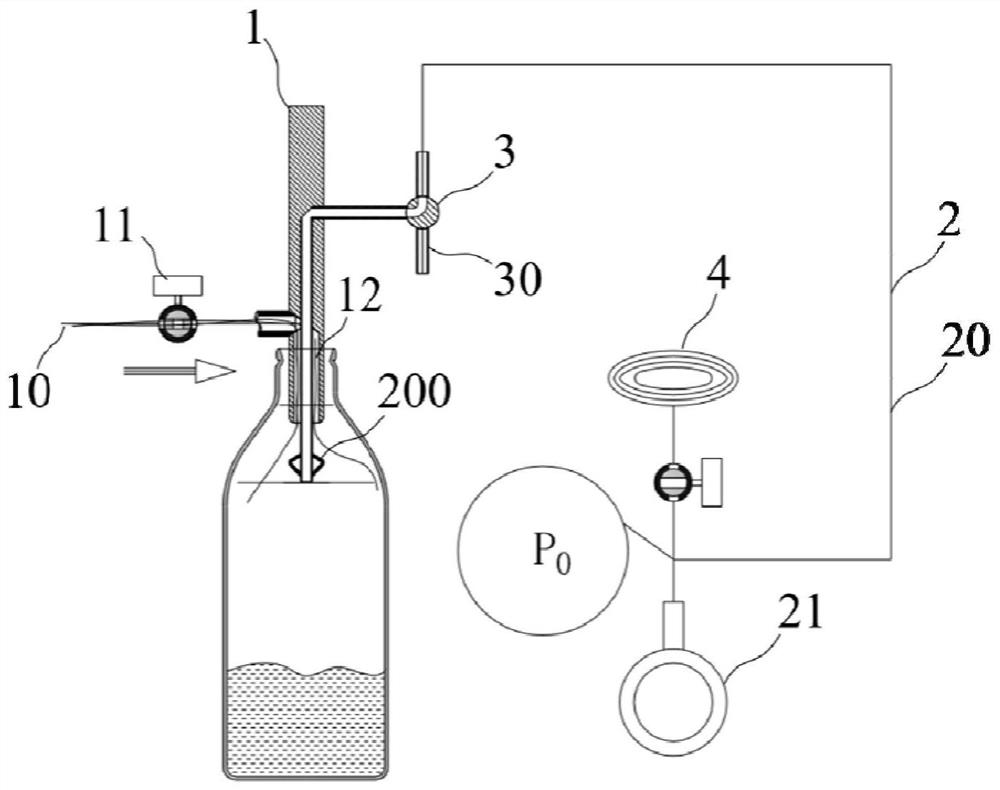

[0077] The non-contact liquid filling device of this embodiment is further improved on the basis of Embodiments 1 and 2, and the height of the end face of the measuring conduit 20 protruding into the container to be filled is consistent with the set height of the filling liquid level .

[0078] With this setting, after the liquid is pumped through the liquid suction pipe 30, the final liquid level in the container stays at the height of the measuring conduit 20 protruding into the end surface, that is, the set height of the filling liquid level, thus ensuring that each filling The liquid level heights are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com