A non-contact liquid high-efficiency filling device

A non-contact, filling device technology, applied in liquid materials, packaging, packaging protection and other directions, can solve the problem of inability to efficiently and accurately control the liquid level height, and achieve accurate and efficient filling liquid level height with small filling errors. , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

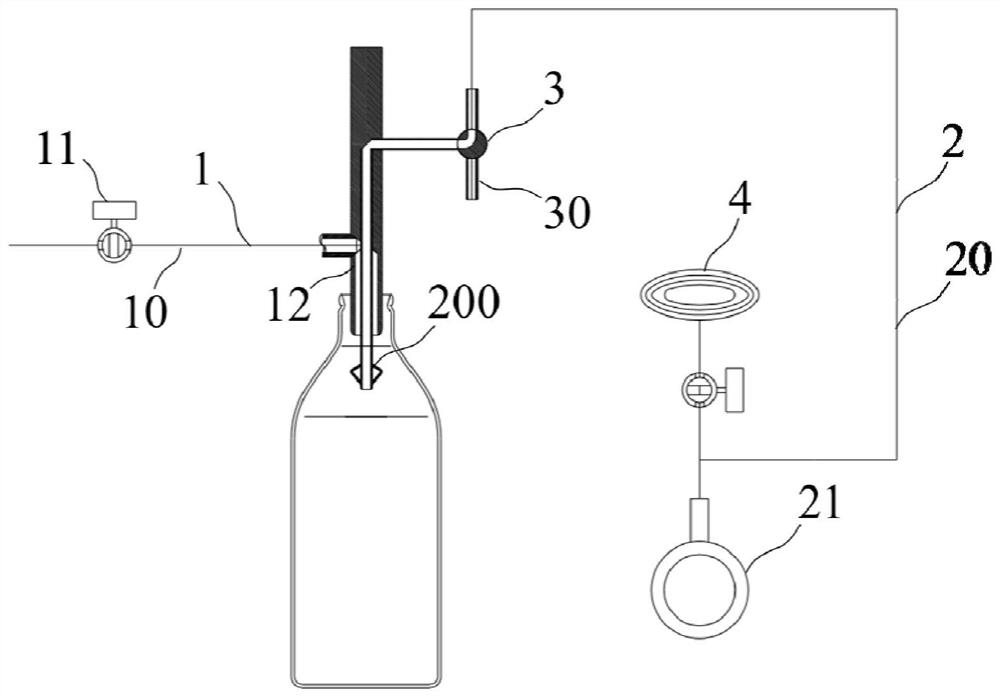

[0065] Such as figure 1 As shown, the non-contact liquid high-efficiency filling device of this embodiment includes,

[0066] Filling unit 1, which is used to fill liquid materials into containers;

[0067] The detection and control unit 2 is used to detect the height of the liquid material in the container to be filled, and to control the start and stop of the filling unit 1;

[0068] The detection and control unit 2 includes a measuring catheter 20 and a pressure sensor 21;

[0069] One end of the measuring conduit 20 extends into the container to be filled, and the other end is connected to the pressure sensor 21;

[0070] The pressure sensor 21 detects pressure changes in the measuring conduit 20 and is connected to the filling unit 1 for signal control to control the start and stop of the filling unit 1; it also includes

[0071] The air source 4 is connected with the measuring conduit 20 to provide constant air pressure in the measuring conduit 20 .

[0072] In the p...

Embodiment 2

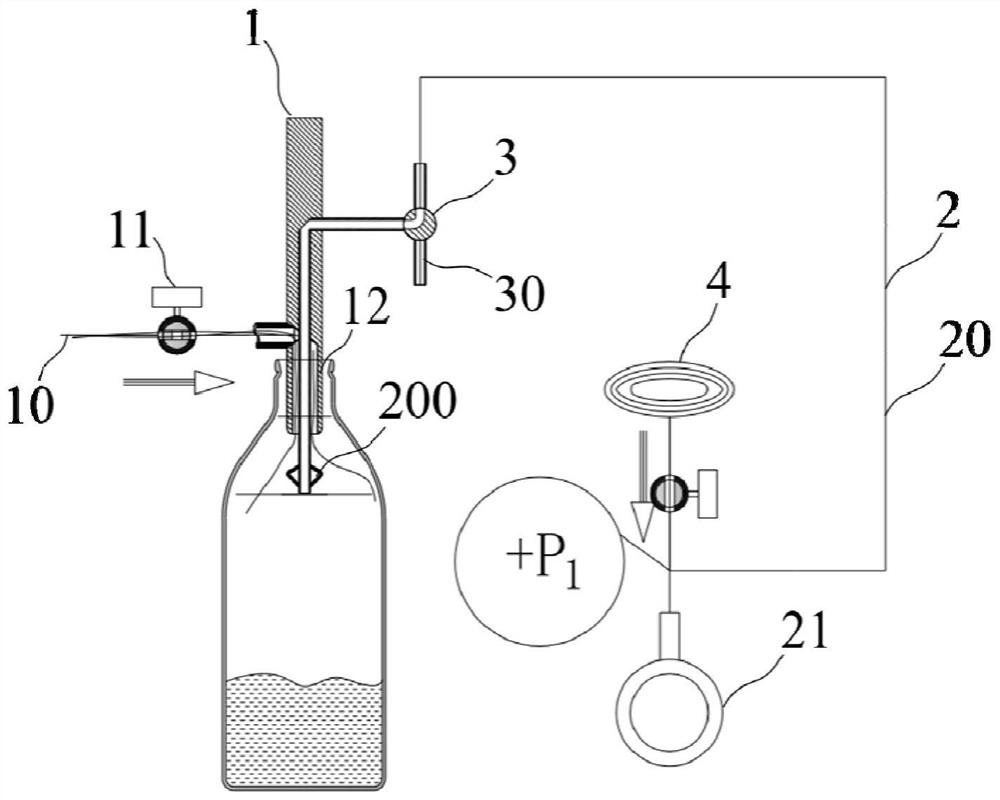

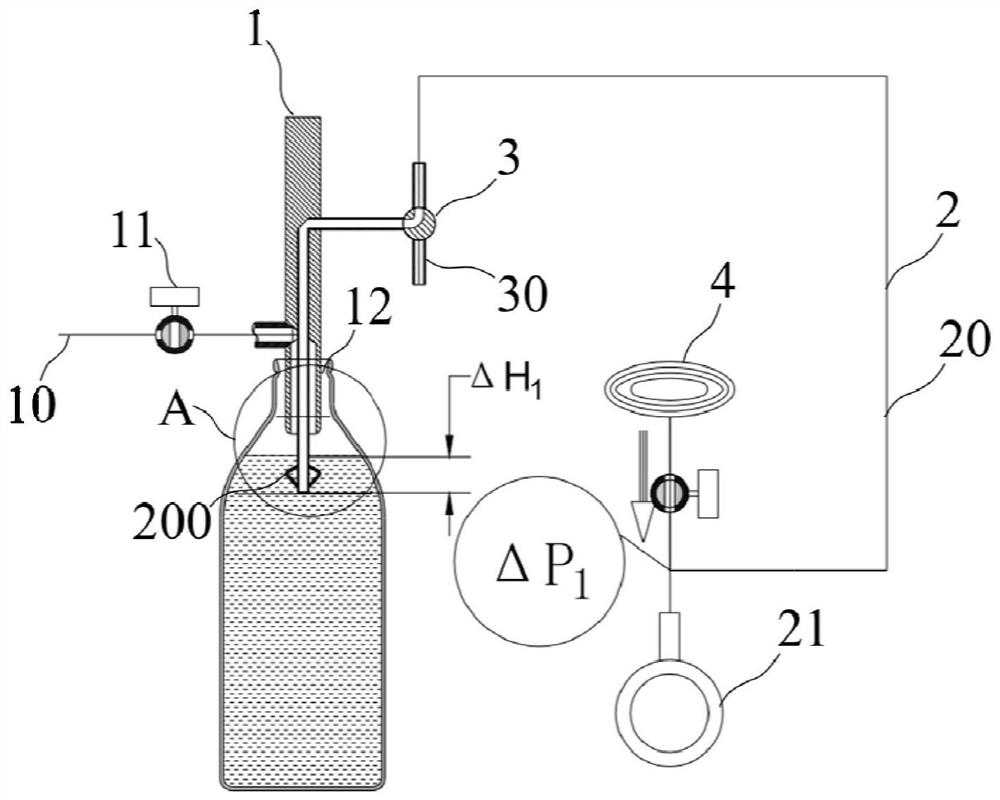

[0078] Such as figure 2 , image 3 and Figure 4 As shown, the non-contact liquid high-efficiency filling device of this embodiment is further improved on the basis of Embodiment 1, and the gas source 4 provides a constant positive pressure for the measurement conduit 20 .

[0079] In this embodiment, the gas source 4 provides a constant positive pressure inside the tube by uniformly blowing air into the measuring tube 20 .

[0080] During filling, there is a positive pressure P in the measuring conduit 20 1, when the liquid level of the liquid material rises to the same height as the mouth of the measuring conduit 20, the pressure in the measuring conduit 20 suddenly increases, and the liquid level of the liquid material continues to rise, which is consistent with the liquid column formed in the measuring conduit 20. Height difference ΔH 1 , at this time there is still ΔP in the measuring catheter 20 1 = ρ 液态物料 ·g·ΔH 1 The pressure increases, where ρ 液态物料 The density...

Embodiment 3

[0082] Such as Figure 5 , Figure 6 and Figure 7 As shown, the non-contact liquid high-efficiency filling device of this embodiment is further improved on the basis of Embodiment 1, and the gas source 4 provides a constant negative pressure for the measurement conduit 20 .

[0083] In this embodiment, the gas source provides a constant negative pressure inside the tube by uniformly pumping air into the measuring tube 20 .

[0084] During filling, there is a negative pressure P in the measuring conduit 20 2 , when the liquid level of the liquid material rises to the same height as the mouth of the measuring conduit 20, because the density of the liquid material is much greater than the gas density, the negative pressure in the measuring conduit 20 suddenly increases, and the 20 pairs of liquid in the measuring tube The liquid level of the material forms a suction effect, and the liquid level of the liquid material in the measuring conduit 20 and the container quickly produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com