Device and method for heat recovery of oil in inner floating roof storage tank

An internal floating roof storage tank and heat recovery technology, applied in steam generation methods, separation methods, chemical instruments and methods using pressure combustion, etc., can solve the problems of difficult evaporation of brine and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

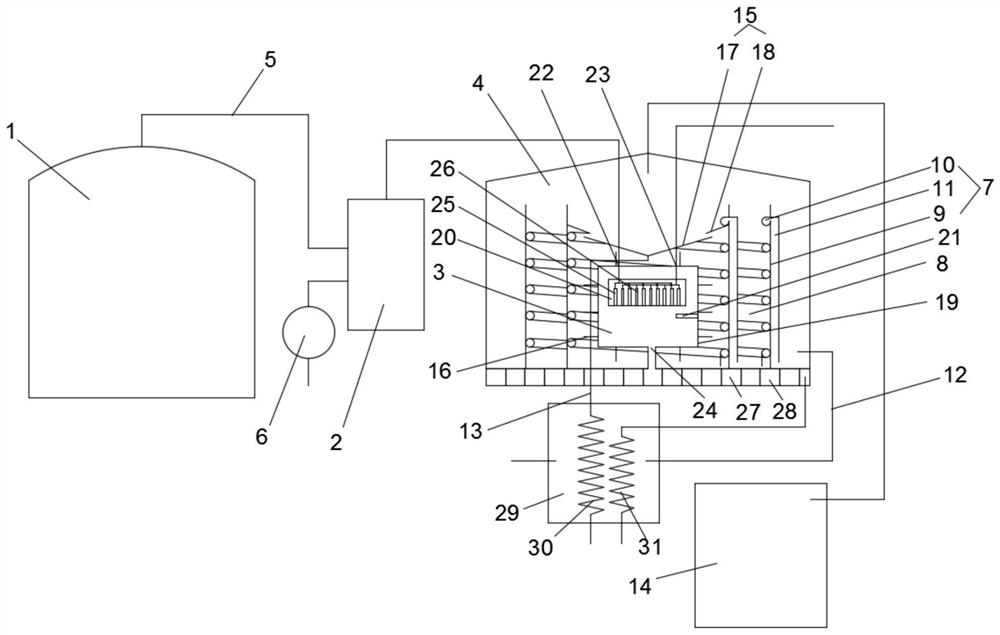

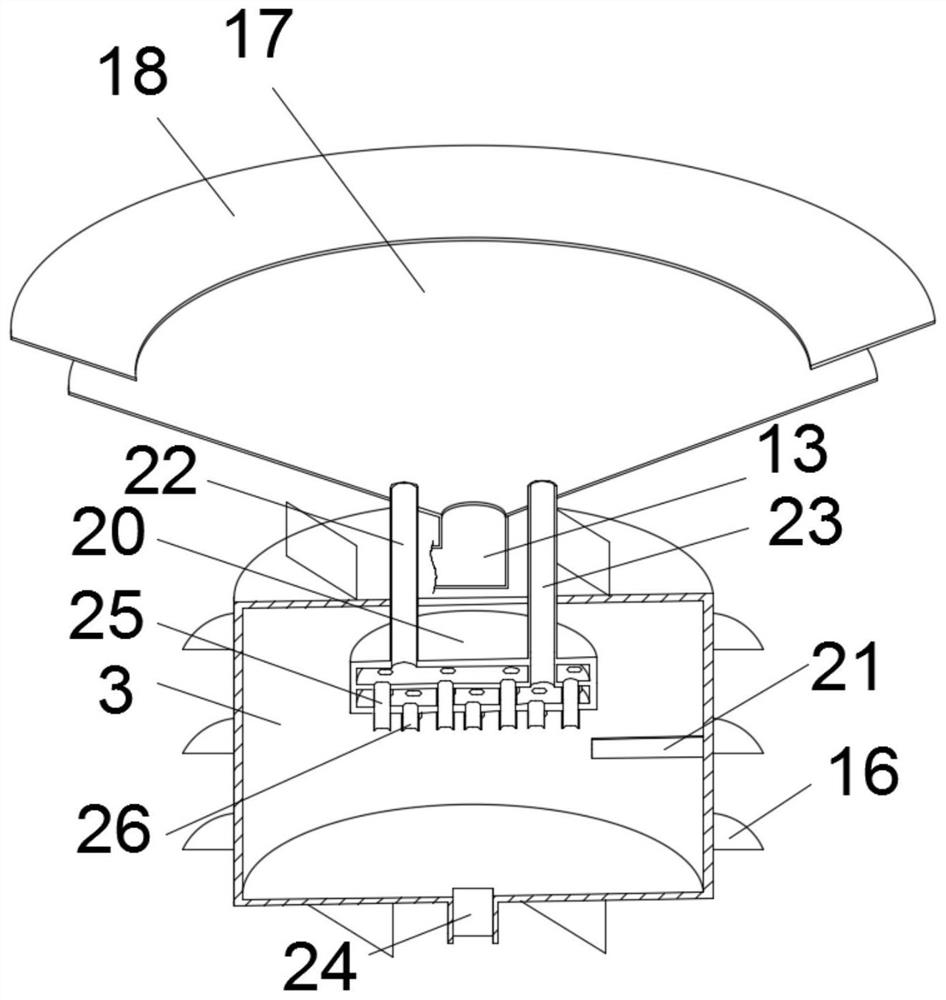

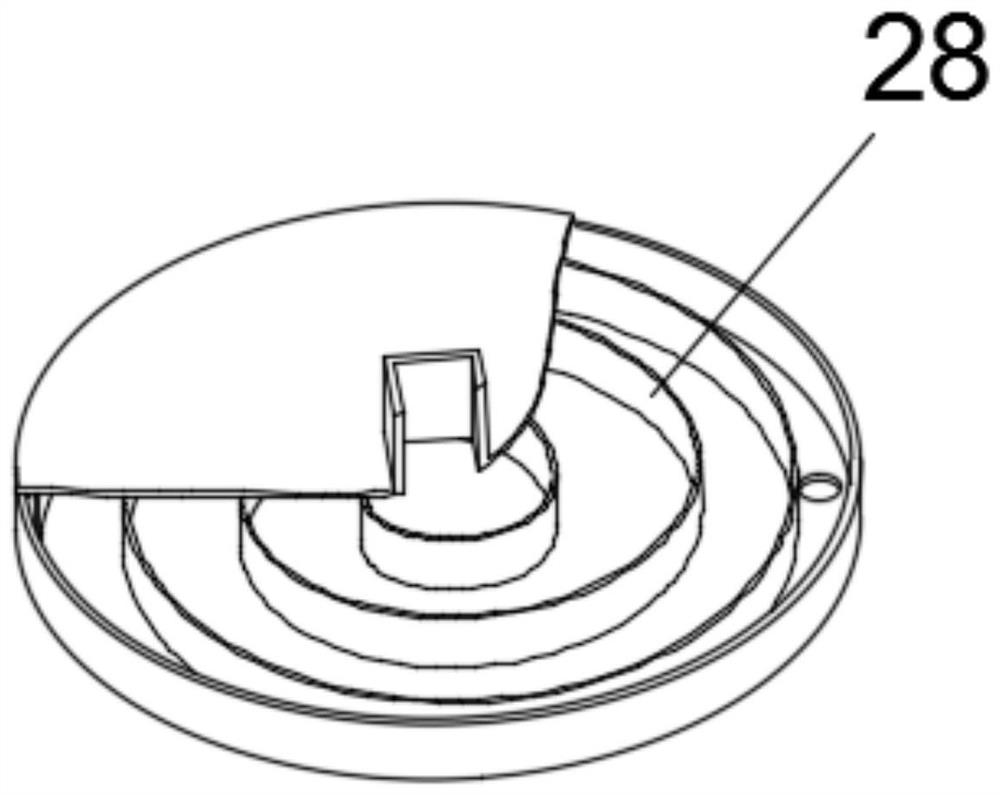

[0028] see Figure 1~4 , a heat recovery device for oil in an internal floating roof storage tank, comprising an internal floating roof storage tank 1, a buffer tank 2, a heating furnace 3 and an evaporation tank 4, the oil and gas collection pipe 5 of the internal floating roof storage tank 1 is connected to the The buffer tank 2 communicates, the buffer tank 2 communicates with the first air pump 6, the exhaust port of the buffer tank 2 communicates with the air inlet 22 of the heating furnace 3, and the heating furnace 3 is arranged in the evaporation tank 4, The evaporation tank 4 is provided with a number of diffusion barrier rings 7 surrounding the heating furnace 3, and the diffusion barrier ring 7 divides the evaporation tank 4 into several independent water storage chambers 8. The diffusion barrier ring 7 Comprising a metal ring 9, a spiral tube 10 and a vertical tube 11, the two sides of the metal ring 9 are respectively provided with the spiral tube 10 and the verti...

Embodiment 2

[0036] see Figure 5 The difference between this embodiment and Embodiment 1 is that the spiral pipe 10 and the vertical pipe 11 are embedded in the metal ring 9, the vertical pipe 11 is provided with a first one-way valve 32, and the water storage A cover 33 is slidingly provided in the chamber 8, and the cover 33 is provided with a sealing gasket 34 in contact with the inner wall of the diffusion barrier ring 7, and the cover 33 is connected to the top of the evaporation tank 4 through an electric telescopic rod 35 , the cover 33 is provided with a second one-way valve 36 . The inner and outer walls of the diffusion barrier ring 7 are smooth, and the cover 33 sliding in the water storage chamber 8 is in sealing contact with the inner wall of the diffusion barrier ring 7 . The cover 33 is connected to the top of the evaporation tank 4 through an electric telescopic rod 35. When the electric telescopic rod 35 is extended, the liquid surface is pressed down. The vertical pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com