Glass bar code tag and wiring terminal adhesive tape automatic adhesion facility

A terminal block and barcode label technology, which is applied in the field of equipment for automatically sticking glass barcode labels and terminal tapes, can solve the problem of single and boring actions, and achieve the effects of eliminating manual operations, improving stability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0037]The model of the mechanical arm used in the embodiment of the present invention is: Morikawa SBR6-05-850.

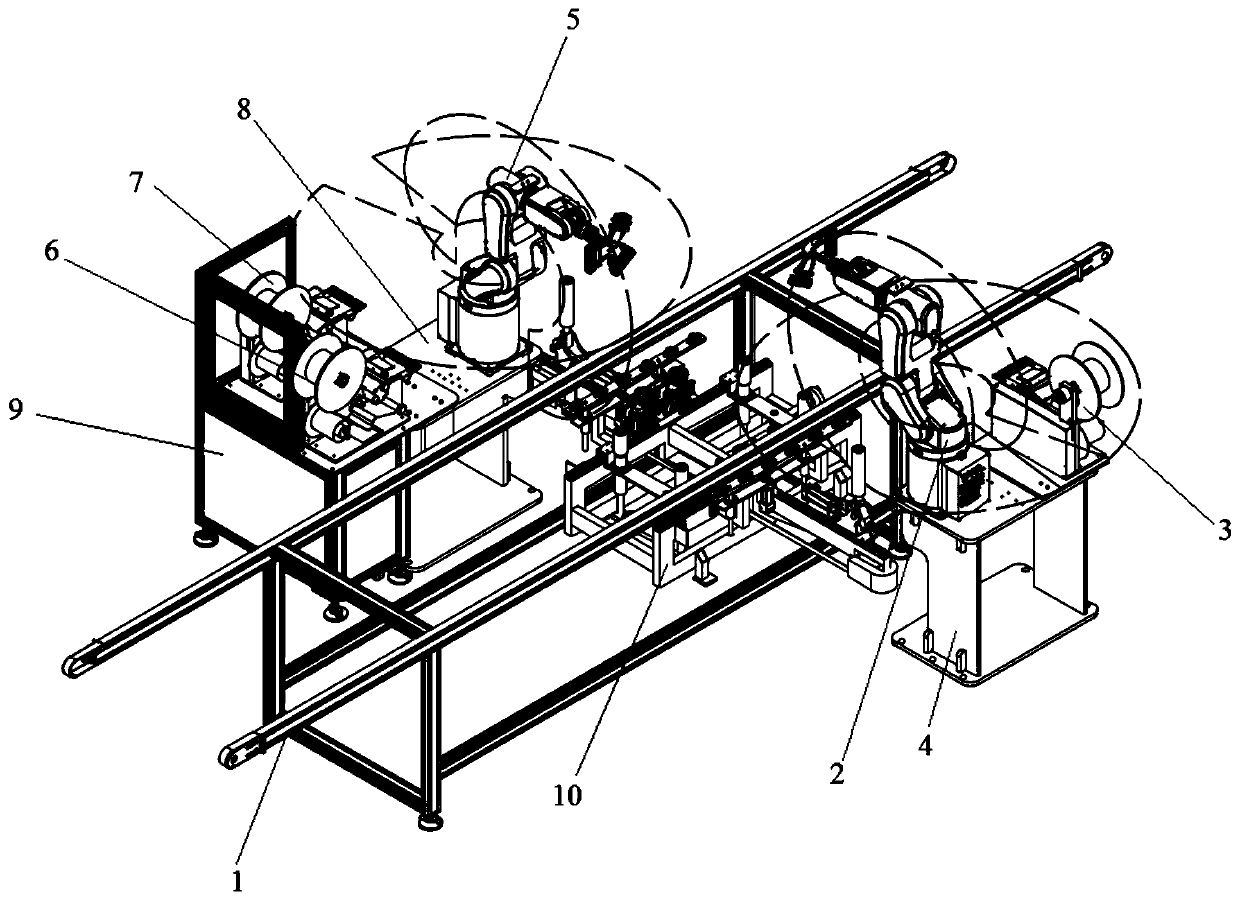

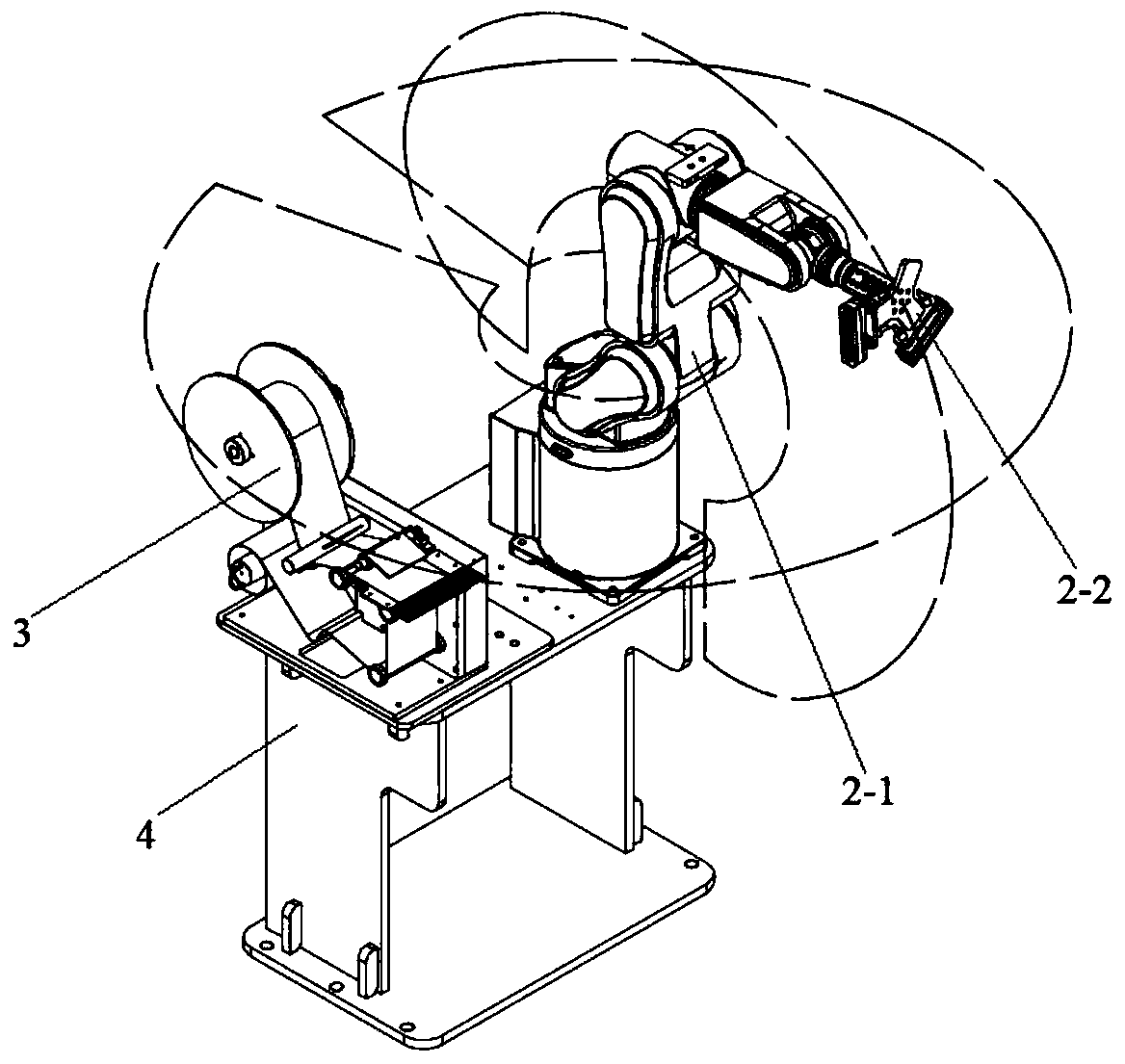

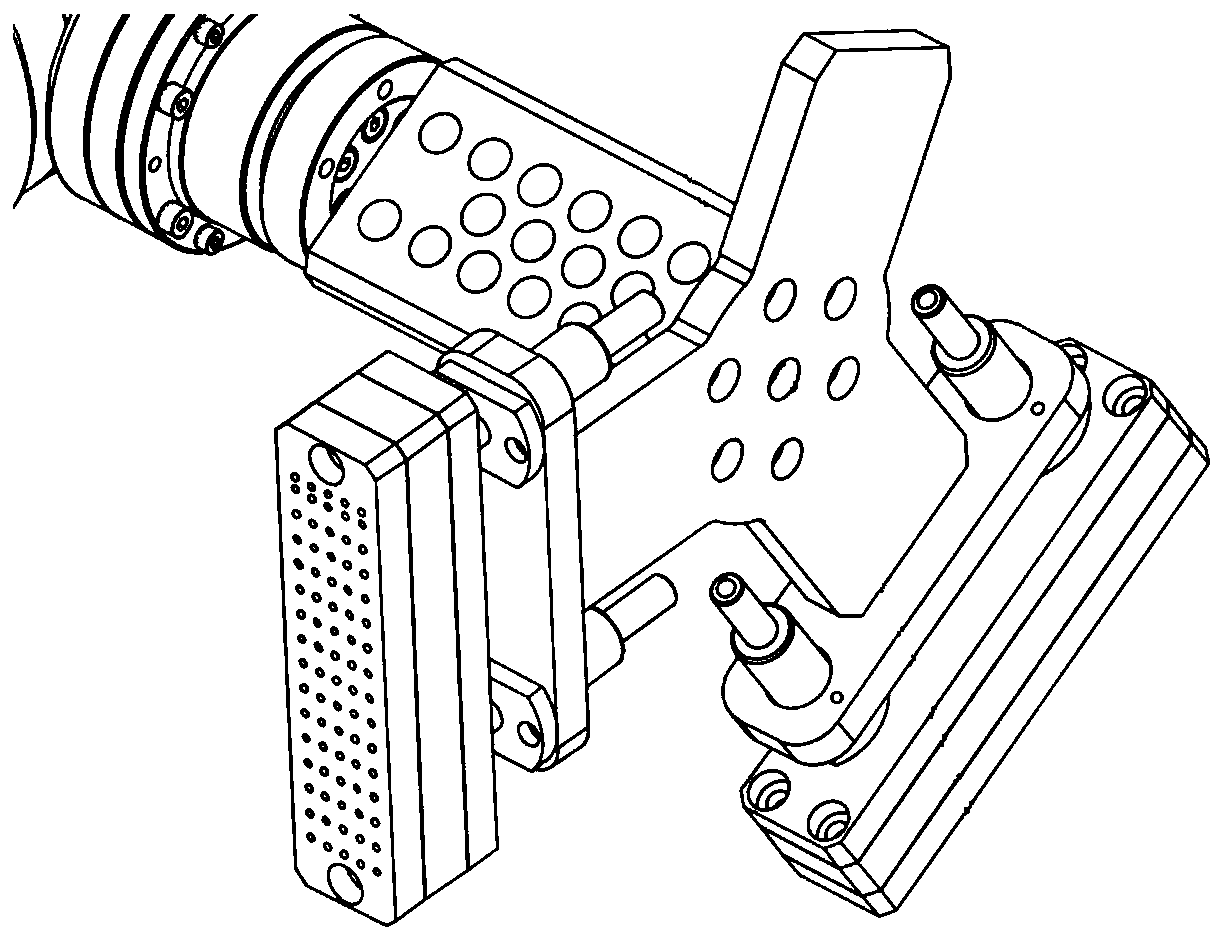

[0038] Such as Figure 1-5 As shown, the equipment for automatically pasting glass barcode labels and terminal tapes of the present invention includes: transmission line 1, robot for applying tape on the right side 2, automatic tape feeding device 3 on the right side, workbench 4 on the right side, robot for pasting tape and labeling on the left side 5. Left tape automatic feeding device 6, left label automatic feeding device 7, left workbench 8, console 9, center positioning mechanism 10. The transmission line 1 is two parallel conveyor belts, the right side adhesive tape robot 2, the right adhesive tape automatic feeding device 3 and the right workbench 4 are arranged on the right side of the transmission line 1, the right side adhesive ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap