A split-type automatic feeding machine and its use method

An automatic feeding and shunting technology, applied in the field of feeders, can solve the problems of inconvenience for different materials to be used in shunting and discharge, material agitation that cannot be input, and easy accumulation of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

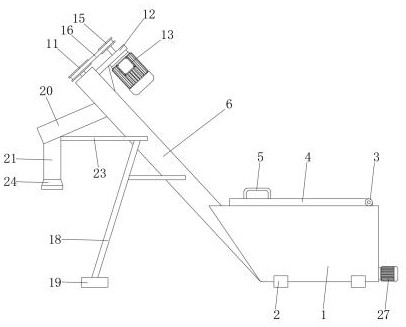

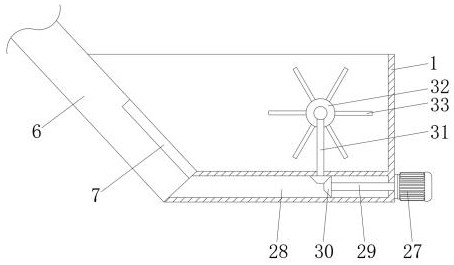

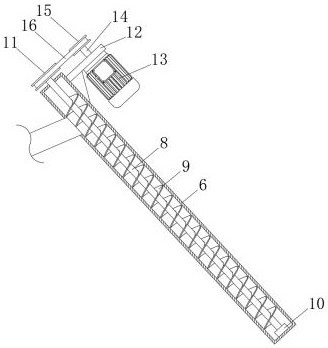

[0033] Such as Figure 1-6As shown, the present invention relates to a split-flow automatic feeding machine, comprising a feeding box body 1, the upper surface of the feeding box body 1 is movably installed with a box door connecting shaft 3, and the upper surface of the feeding box body 1 passes through the box door connecting shaft 3 A sealed box door 4 is movable, and a lifting handle 5 is fixedly installed on the upper surface of the sealed box door 4. The inner side of the feeding box body 1 is fixedly installed with a feeding conveying pipe 6, and the bottom of the feeding conveying pipe 6 is provided with a feeding opening. The groove 7, the inner surface of the feeding delivery pipe 6 is rotated with a blade rotating rod 8, and the outer surface of the blade rotating rod 8 is provided with a rotating blade 9, and the outer surface of the lower end of the blade rotating rod 8 is movably connected with a rotating rod positioning seat 10, and the blade The outer surface o...

Embodiment 2

[0036] On the basis of embodiment 1, a kind of use method of split type automatic feeding machine comprises the following steps:

[0037] S1: The feeding box body 1 and the supporting and fixing frame 18 are positioned and placed, and the feeding box body 1 and the supporting and fixing frame 18 are supported and fixed through the box foot pad 2 and the fixing frame foot pad 19 contacting the ground during placement;

[0038] S2: Align the outlets of the first shunt pipe 21 and the second shunt pipe 22 with the feeding position, grasp the pull handle 5 and pull it up to rotate and open the sealed box door 4 around the box door connecting shaft 3, and place the materials to be output Poured into the inside of the feeding box 1, the material enters the inside of the feeding box 1 and simultaneously enters the feeding conveying pipe 6 through the feeding slot 7 and contacts the rotating blade 9;

[0039] S3: The rotating motor 13 is powered on, the rotating motor 13 is energized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com