Separation and purification device for microplastics in marine sediments and using method

A technology for marine sediments and microplastics, which is applied in the preparation of test samples, etc., can solve the problems of poor data reliability and complicated extraction devices, and achieve the effects of easy removal, improved suspension effect, and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Collect sediments in shallow coastal areas in environmentally stable areas, put them in sample bags, and bring them back to the laboratory for processing;

[0049] 2. Dry the collected sediments in an oven at 95°C to remove bulky substances and refine them;

[0050] 3. Prepare 3.0L of saturated sodium chloride solution, prepare biological tissue digestion solution (with an activity of 10u / mL~15u / mL), and prepare acid solution such as concentrated sulfuric acid;

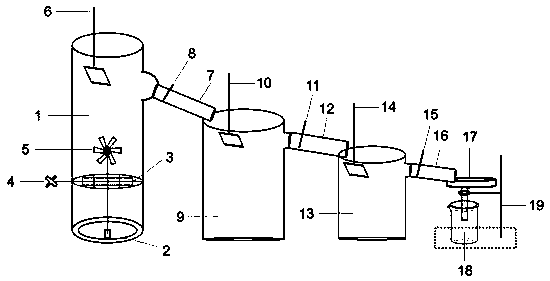

[0051] 4. Add the refined sediment to the partition of the density liquid, add the density liquid, and turn on the stirrer (160rpm) for full stirring;

[0052] 5. Open the pore switch of the partition to make the sediment sink and stand still for 30 minutes, then open the scraper to let the suspended matter enter the branch pipe and flow into the primary purification bottle;

[0053] 6. Add the prepared enzymatic hydrolysis solution into the primary purification bottle, turn on the stirring function of the ...

Embodiment 2

[0058] 1) Collect 500g of marine sediment, dry it at 95°C, and refine the bulk sediment;

[0059] 2) Place the treated sediment at the partition 3 in the density liquid bottle 1, add 3.0L of saturated NaCl density liquid, stir well, and the rotation speed is 160rpm to form a suspension;

[0060] 3) Open the pore switch of the partition 3, so that the high-density sediment material sinks in the pores of the partition to achieve the separation of high-density and low-density materials; the partition 3 can be fully opened to place the agitator at a density The bottom of the liquid bottle can be partially opened to allow the sediment to sink from the pores (5mm ~ 10mm in diameter);

[0061] 4) Activate the scraper to make the substance in the upper suspension flow from the conduit into the primary purification bottle;

[0062] 5) Add biological tissue digestion solution (activity: 10u / mL~15u / mL) into the first-level purification bottle, start the stirring of the scraper (rotation...

Embodiment 3

[0066] Pulverize the purchased low-density polyethylene particles on a pulverizer, weigh 0.5234g, add 0.432g of microfiber products, and mix the two with 300g of soil evenly, as a simulated sediment sample.

[0067] The primary enzyme digestion step was removed, and the acid digestion was directly carried out, and other operating steps were consistent with Example 1.

[0068] Finally, the microplastic particles obtained on the filter disc are dried and stored for detection. The recovery rate of the sample reached 97.6%, and the microparticles were detected by infrared spectroscopy, all of which were microplastics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com