Lifting device with self-adaptive uniform loading function

A lifting device, self-adaptive technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of increased load and energy consumption, inapplicability, large space occupied, etc., to reduce eccentric load and stress concentration, improve allowable Effects of load, load reduction and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the "connection" mentioned in this application and the words used to express "connection", such as "connected", "connected", etc., include not only the direct connection between a certain component and another component, but also the direct connection of a certain component. One part is connected to another part through other parts.

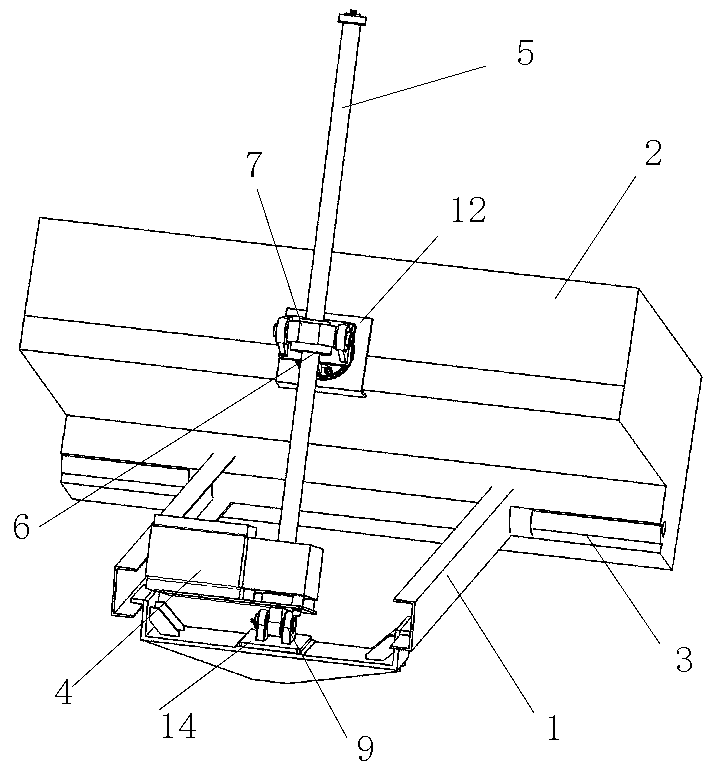

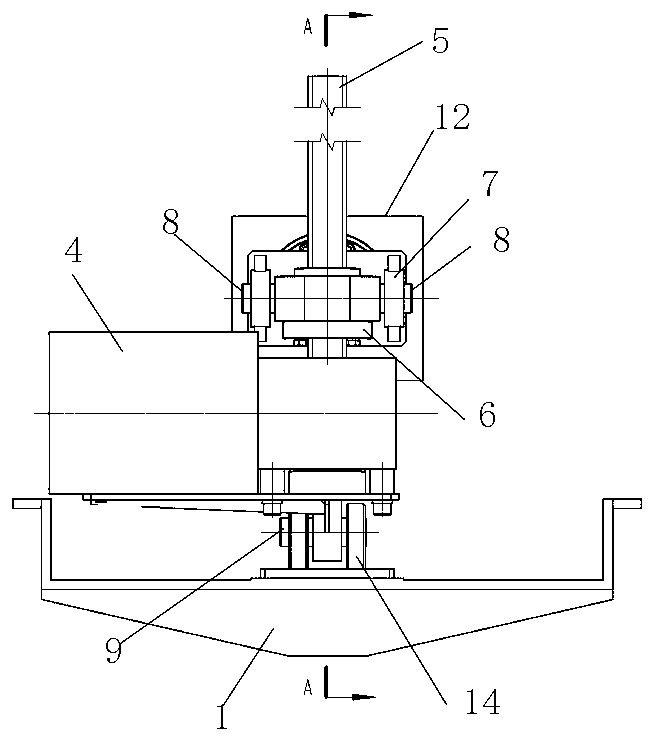

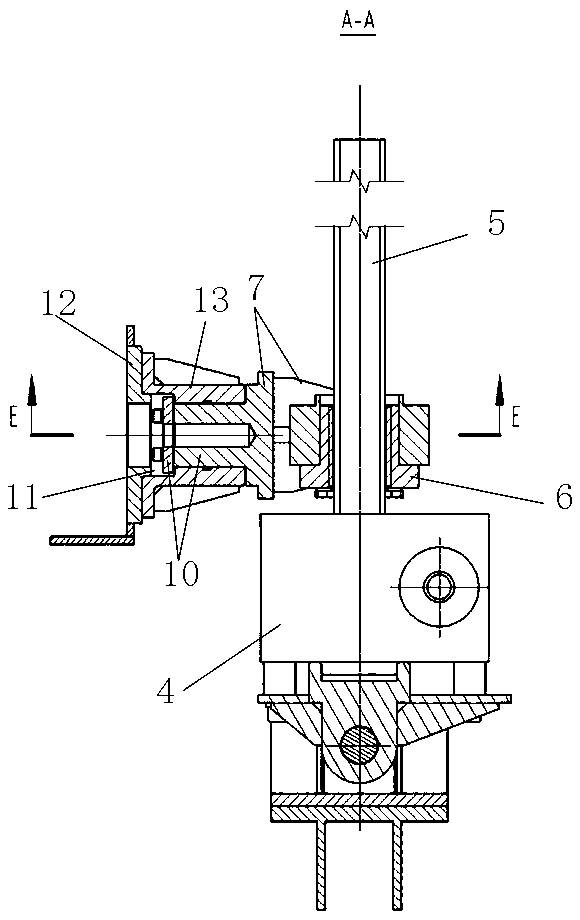

[0021] like figure 1 - As shown in 5, the lifting device with self-adaptive load balancing function includes a bottom plate 1 and a box body 2 connected with the bottom plate 1 around the rotary shaft 3 in rotation, a hinged screw nut mechanism between the bottom plate 1 and the box body 2, and a screw nut mechanism. The rod and nut mechanism includes a driving mechanism 4 , a screw 5 driven by the driving mechanism 4 and a nut 6 arranged on the leading screw 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com