Welding method and weld joint

A welding method, technology of the welding department, applied in the direction of welding/welding/cutting articles, welding equipment, welding medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Hereinafter, the present invention will be described based on the embodiments. In addition, this invention is not limited to the following embodiment. Various modifications can be added to the following embodiments within the same and equivalent scope as the present invention.

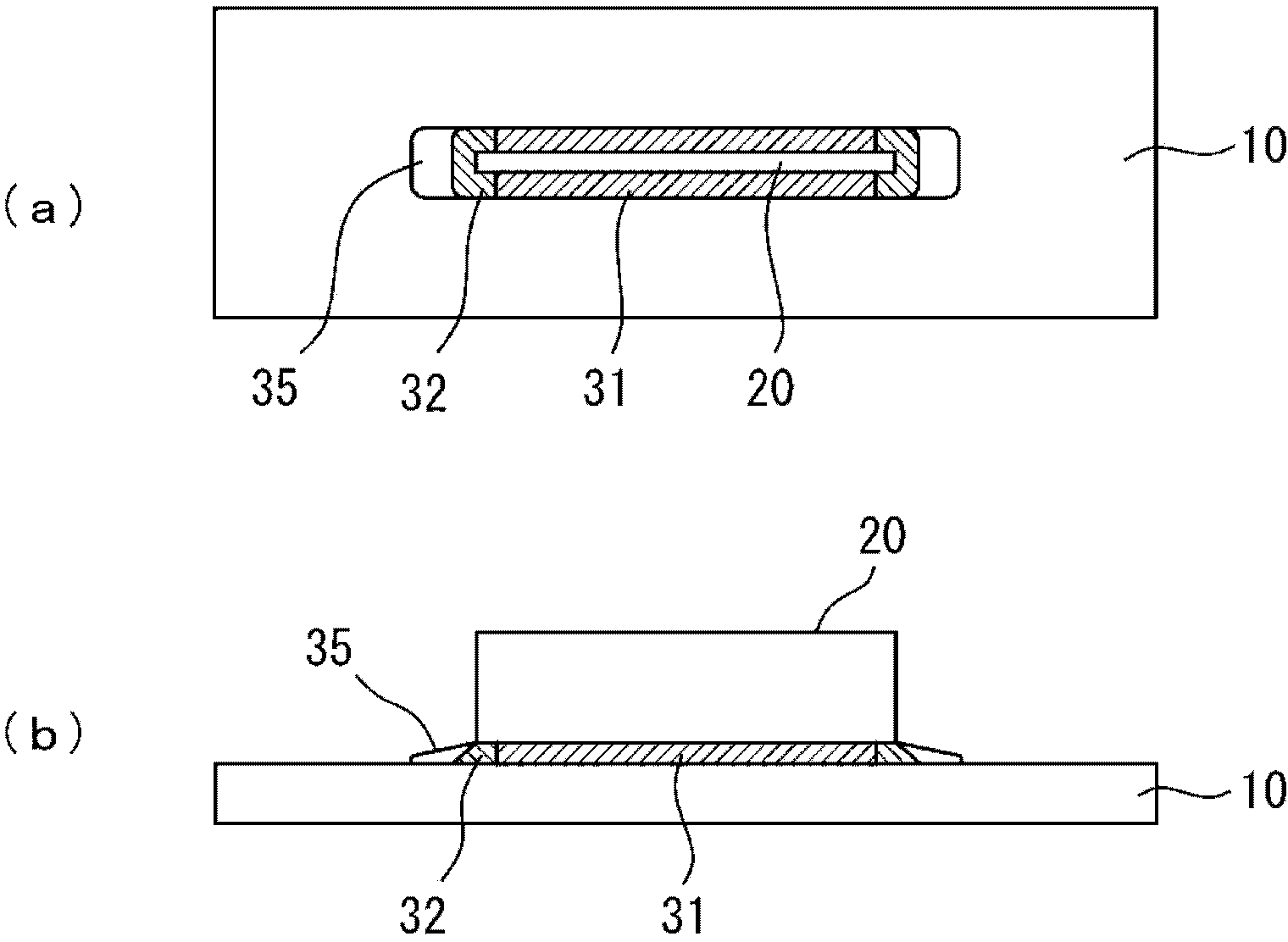

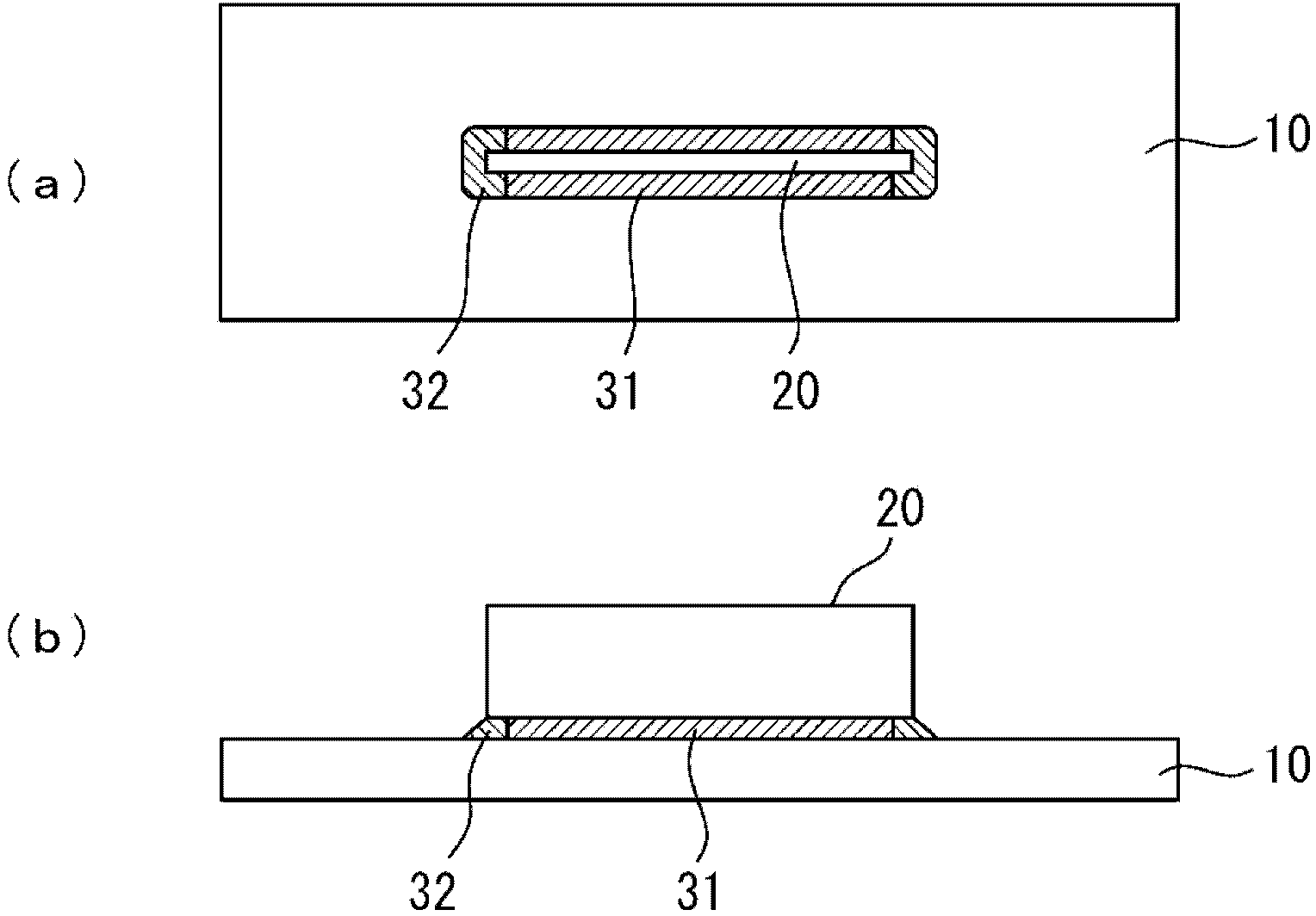

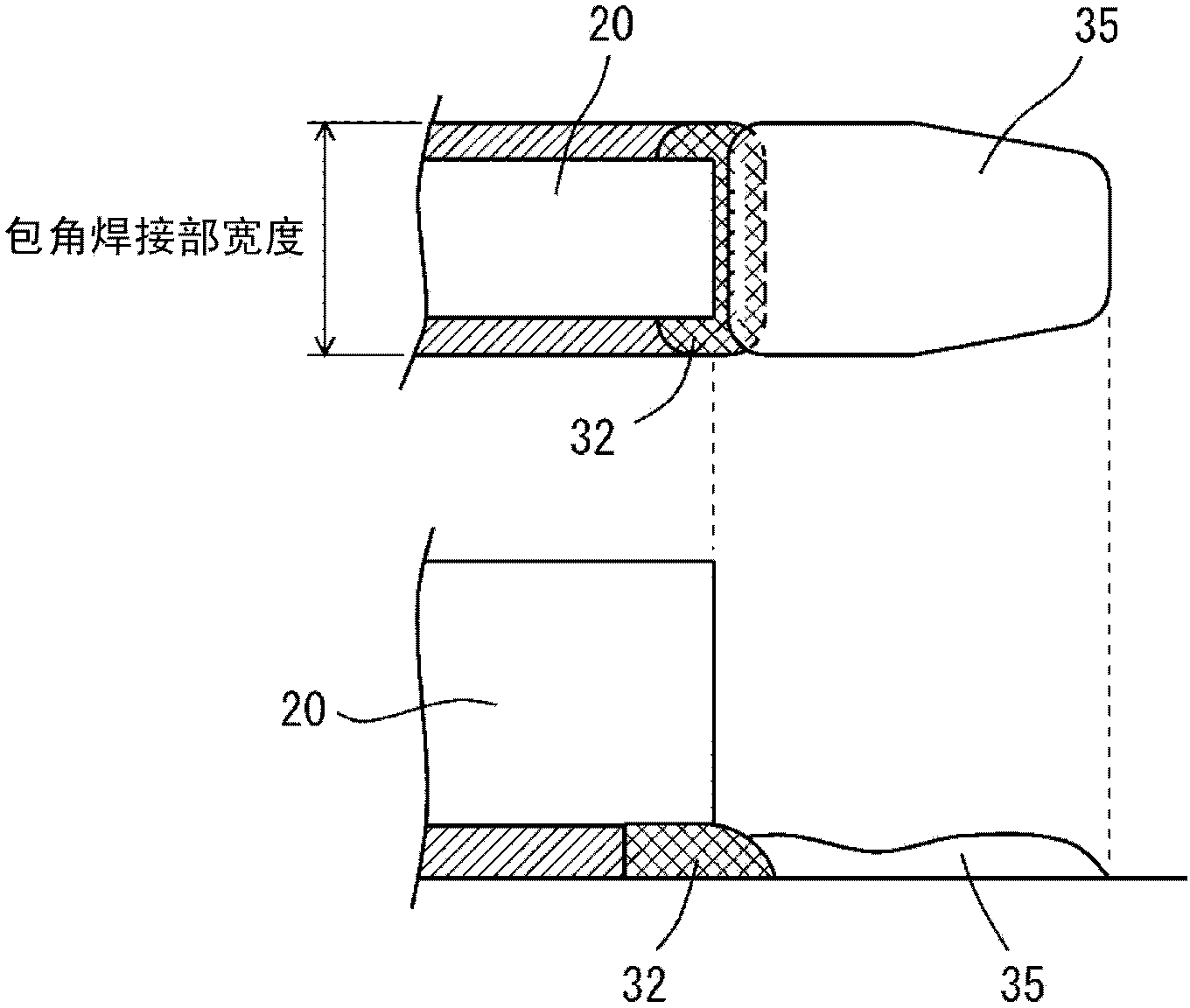

[0096] First, an outline of a welded joint according to the present invention and an outline of a conventional welded joint will be described using the drawings. figure 1 Table shows the welded joint made by the welding method of the present invention, in addition, figure 2 The table in the table shows welded joints produced by conventional welding methods. figure 1 , 2 In each drawing, (a) is a plan view, and (b) is a side view.

[0097] figure 2 In the conventional welded joint shown in , conventional fillet welding is used to weld a flat plate 10 as a base material to a gusset plate 20 to form a welded portion 31 and a fillet welded portion 32 on the lower side of the gusset plate 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com