A kind of zirconium phosphate-melamine cyanurate reactive flame retardant and its preparation method and application

A technology of melamine cyanurate and reactive flame retardant, which is applied in the field of zirconium phosphate-melamine cyanurate reactive flame retardant and its preparation, can solve the demanding requirements of curing and foaming process control, and the viscosity of the mixed system Large impact, general reactivity, etc., to achieve the effect of improving mechanical properties, improving compatibility, and improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

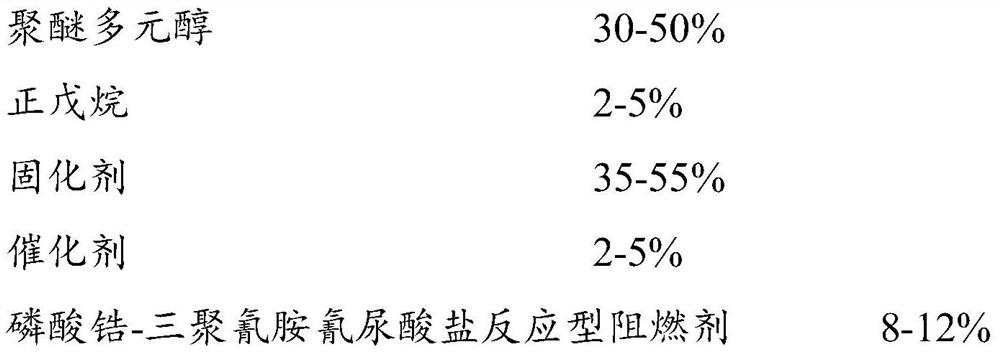

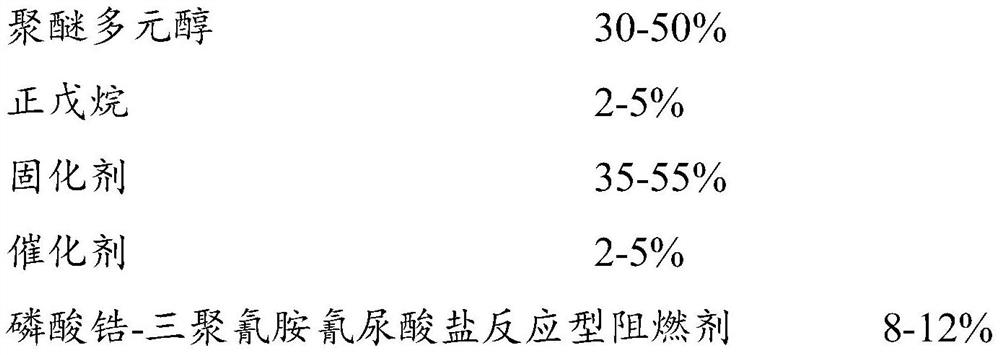

Method used

Image

Examples

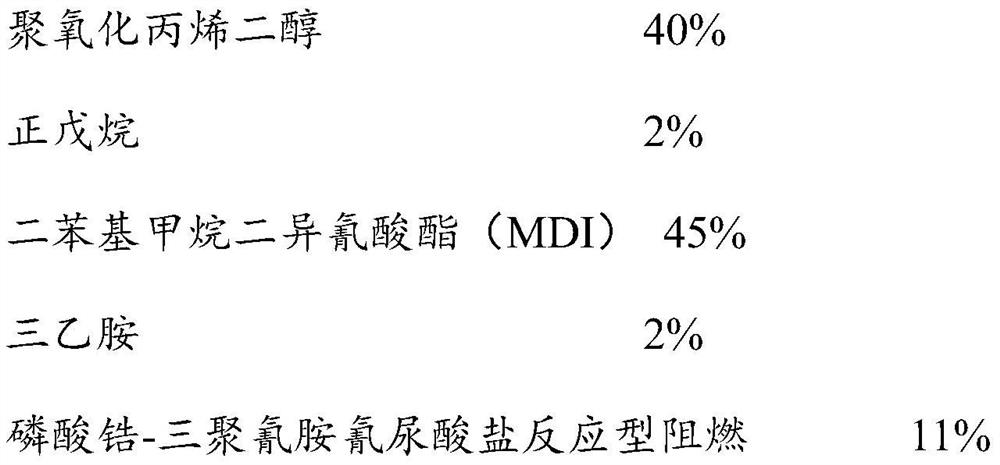

Embodiment 1

[0025] Step (1): Dissolve ethanolamine in distilled water, control the molar ratio of ethanolamine and distilled water to 1:1, and then carry out high-speed stirring treatment, the stirring speed is 500r / min, and the stirring time is 20min to obtain ethanolamine aqueous solution; zirconium phosphate powder Dissolve in distilled water, control the liquid-solid ratio to 70ml / g, then carry out high-speed stirring, the stirring speed is 500r / min, and the stirring time is 20min, to obtain an aqueous solution of zirconium phosphate;

[0026] Step (2): mixing the ethanolamine aqueous solution obtained in step (1) with the zirconium phosphate aqueous solution obtained in step (1), and ultrasonically treating it for 20 minutes to obtain a zirconium phosphate swelling and gelling solution;

[0027] Step (3): mixing melamine cyanurate with the zirconium phosphate swelling gelling liquid obtained in step (2), the liquid-solid ratio of the zirconium phosphate swelling gelling liquid and the...

Embodiment 2

[0032] Step (1): dissolving diethanolamine in distilled water, controlling the molar ratio of diethanolamine and distilled water to be 1:3, then carrying out high-speed stirring treatment, the stirring speed is 700r / min, and the stirring time is 45min to obtain an aqueous solution of diethanolamine; Dissolve the zirconium phosphate powder in distilled water, control the liquid-solid ratio to 70ml / g, and then perform high-speed stirring at a stirring speed of 1000r / min for a stirring time of 45min to obtain an aqueous solution of zirconium phosphate;

[0033] Step (2): mixing the aqueous diethanolamine solution obtained in step (1) with the zirconium phosphate aqueous solution obtained in step (1), and ultrasonically treating it for 30 minutes to obtain a zirconium phosphate swelling and gelling solution;

[0034] Step (3): mixing melamine cyanurate with the zirconium phosphate swelling gelling liquid obtained in step (2), the liquid-solid ratio of the zirconium phosphate swelli...

Embodiment 3

[0039]Step (1): Dissolve isopropanolamine in distilled water, control the molar ratio of isopropanolamine and distilled water to 1:3, and then carry out high-speed stirring treatment with a stirring speed of 1000r / min and a stirring time of 60min to obtain alcoholized aqueous solution; the zirconium phosphate powder was dissolved in distilled water, the liquid-solid ratio was controlled to be 100ml / g, and then stirred at a high speed with a stirring speed of 1000r / min and a stirring time of 60min to obtain an aqueous solution of zirconium phosphate;

[0040] Step (2): mixing the aqueous solution of alcoholizing agent obtained in step (1) with the aqueous solution of zirconium phosphate obtained in step (1), and ultrasonically treating it for 30 minutes to obtain a zirconium phosphate swelling and gelling solution;

[0041] Step (3): mixing melamine cyanurate with the zirconium phosphate swelling gelling liquid obtained in step (2), the liquid-solid ratio of the zirconium phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com