Aluminum alloy for capacitor shell and aluminum alloy strip preparation method thereof

A technology of aluminum alloy strips and capacitors, applied in the field of capacitor processing, can solve the problems of scrapped capacitors, packaging paint film peeling off, low strength, etc., and achieve the effects of good stamping processability, good paintability, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

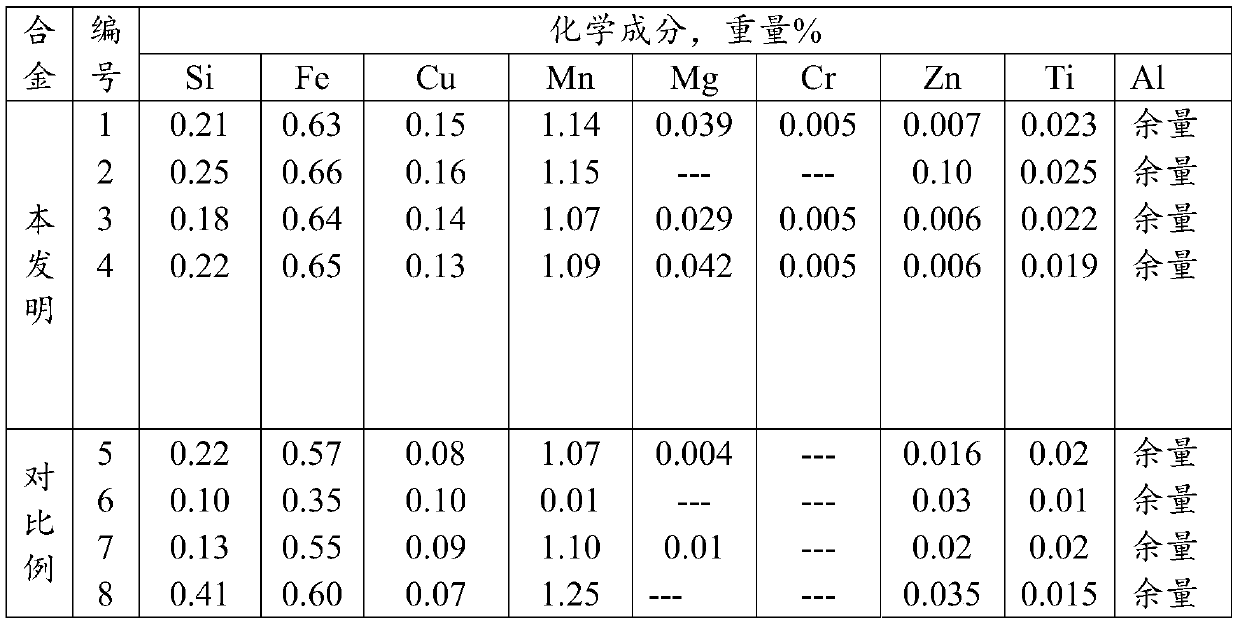

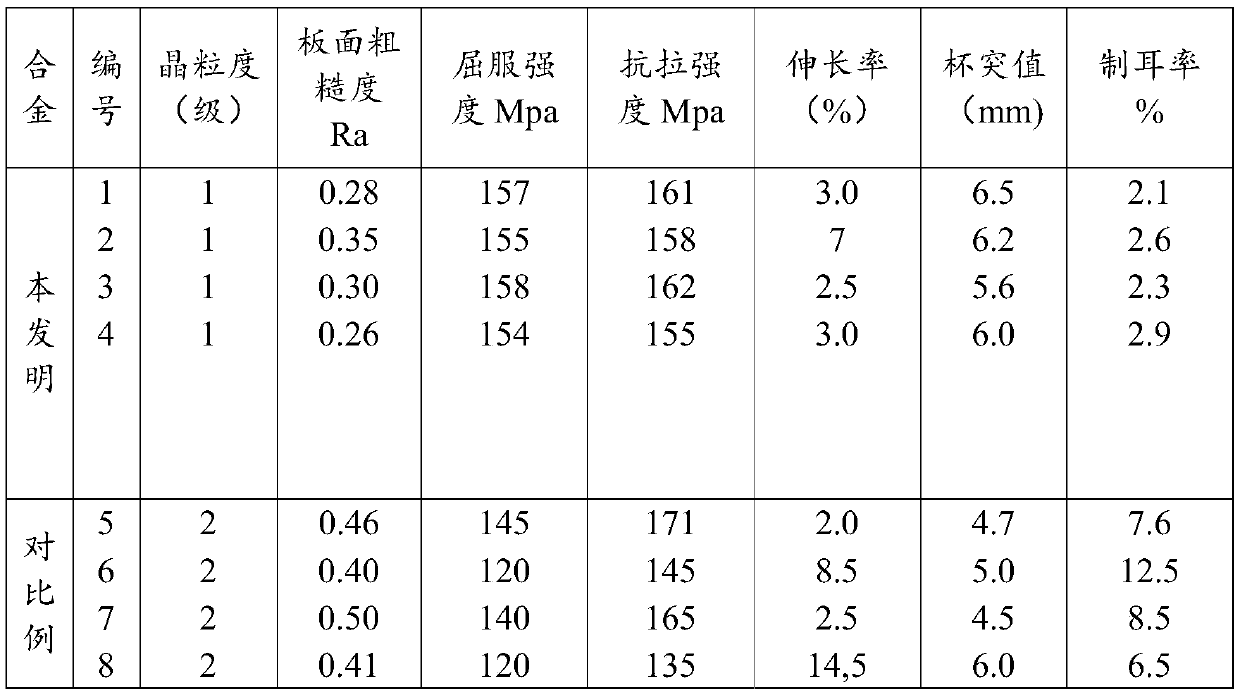

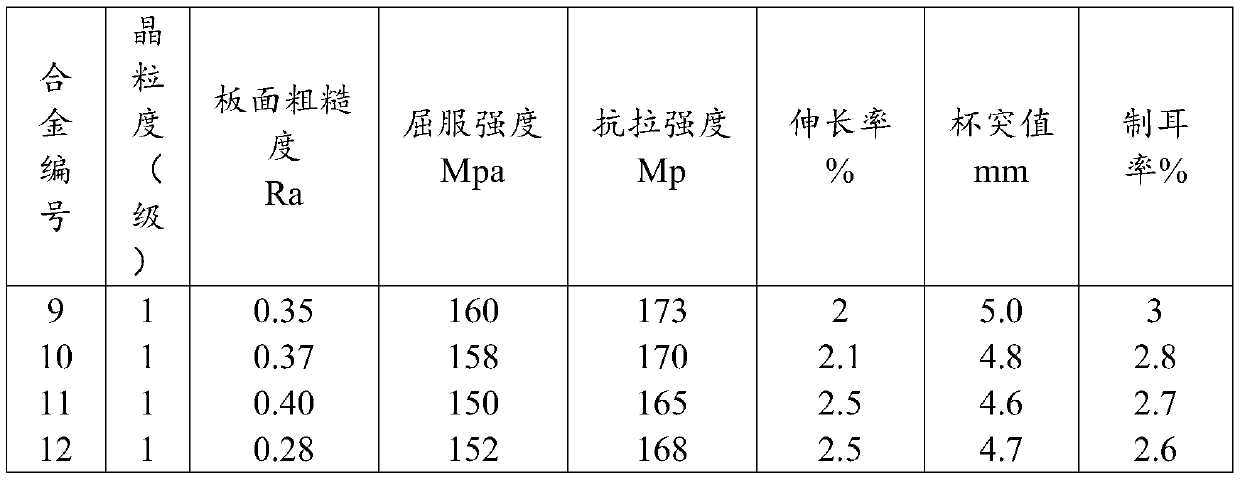

Examples

preparation example Construction

[0017] According to the method for preparing an aluminum alloy plate and strip according to the embodiment of the second aspect of the present invention, the aluminum alloy for a capacitor shell according to the embodiment of the first aspect of the present invention is utilized, and includes the following steps: casting the above-mentioned aluminum alloy for a capacitor shell into an ingot; The above ingot is cut into one section or several sections; the above cut ingot is subjected to soaking treatment, and then hot rolled to obtain a hot rolled plate; the above hot rolled plate is subjected to the first intermediate annealing treatment; The sheet material subjected to the secondary intermediate annealing treatment is subjected to cold rolling treatment; the above-mentioned sheet material subjected to the cold rolling treatment is subjected to the second intermediate annealing treatment;

[0018]After preparing the aluminum alloy composition of the first aspect of the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com