An Elastic Mechanism with Expandable Parallel Springs

A clockwork spring and elastic mechanism technology, applied in vehicle springs, elastic suspensions, springs/shock absorbers, etc., can solve the problems of low energy density, small inner hole of clockwork spring, small torque, etc., and achieve high energy density , Small size, high storage power density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

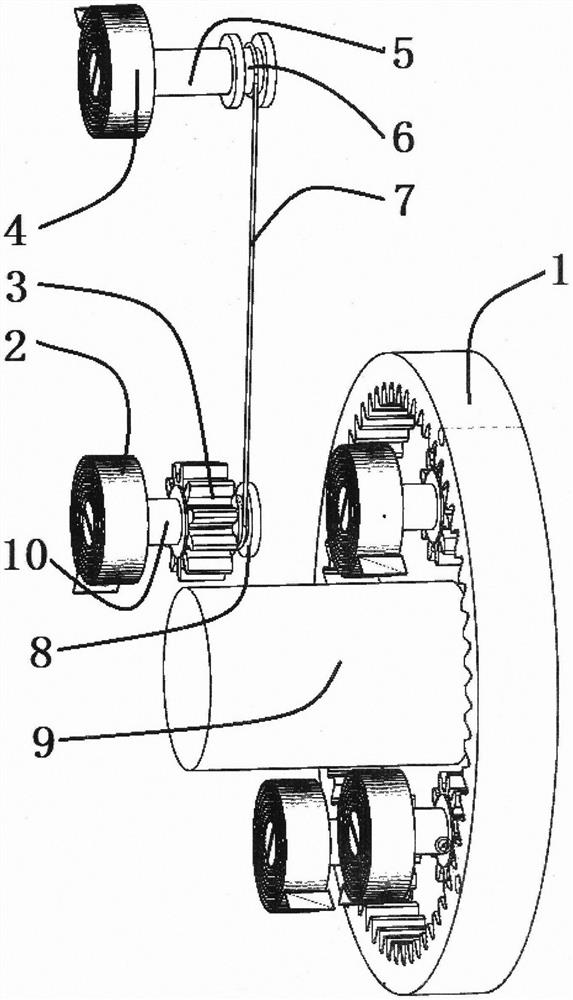

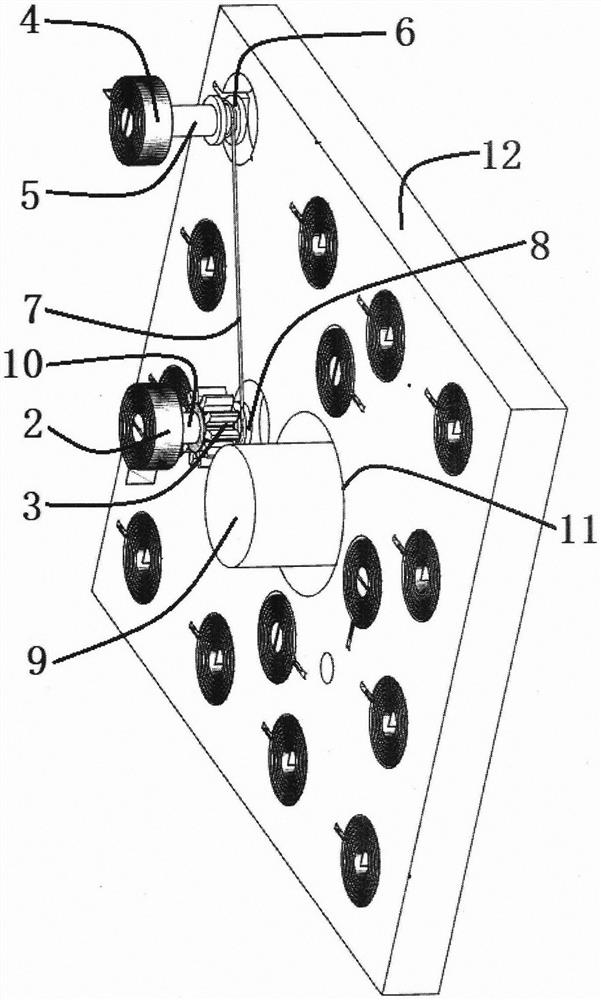

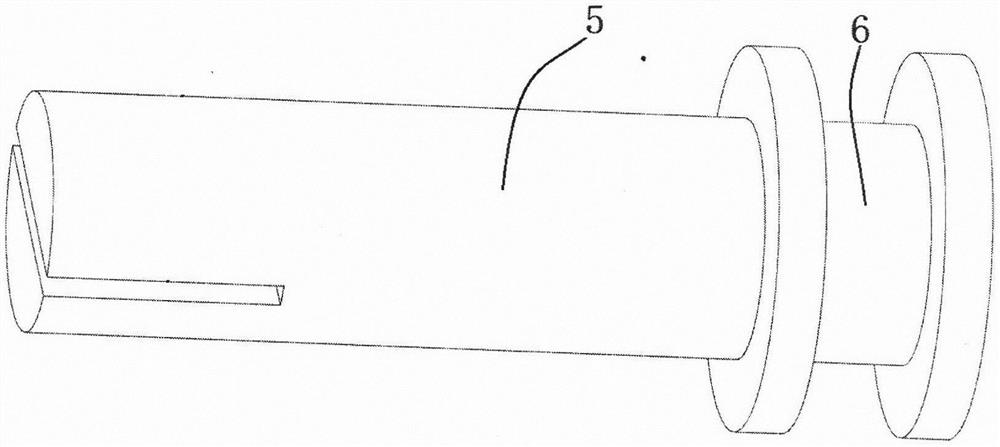

[0014] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , an elastic mechanism that can expand the number of springs in parallel is characterized by: ring gear 1 and gear 3 are installed in internal mesh, the number of teeth of ring gear 1 is 89, the number of teeth of gear 3 is 20, gear 3 is arranged circumferentially, gear 3 The number of gears is 6, the modulus of the ring gear 1 and the gear 3 is 1, and the thickness is 20 mm. The gear shaft 10 is coaxially connected to the gear 3. The diameter of the gear shaft 10 is 10 mm, and the length is 40 mm. Steel wire rope groove 8, the width of steel wire rope groove 8 is 3mm, the depth is 2mm, the other end of gear shaft 10 is connected and installed with the inner ring of clockwork spring 2, and one end of expansion shaft 5 is provided with expanded wire rope groove 6, and the width of expanded wire rope groove 6 The length is 2mm, and the depth is 2mm. A steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com