GVV valve pressure maintaining structure and GVV valve

A pressure cylinder and valve body technology, applied in the direction of valve housing structure, valve details, safety valves, etc., can solve the problems of installation space environment restrictions, increase the overall structure height, etc., achieve oil and gas separation, reduce valve body height, and save energy. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

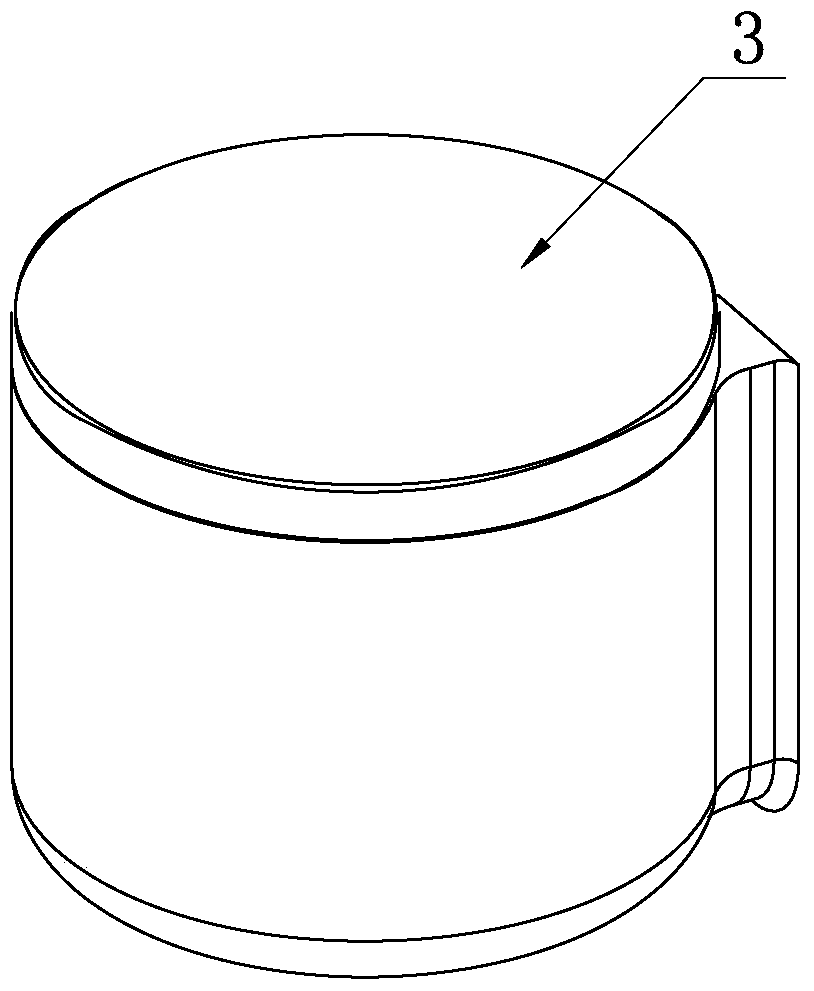

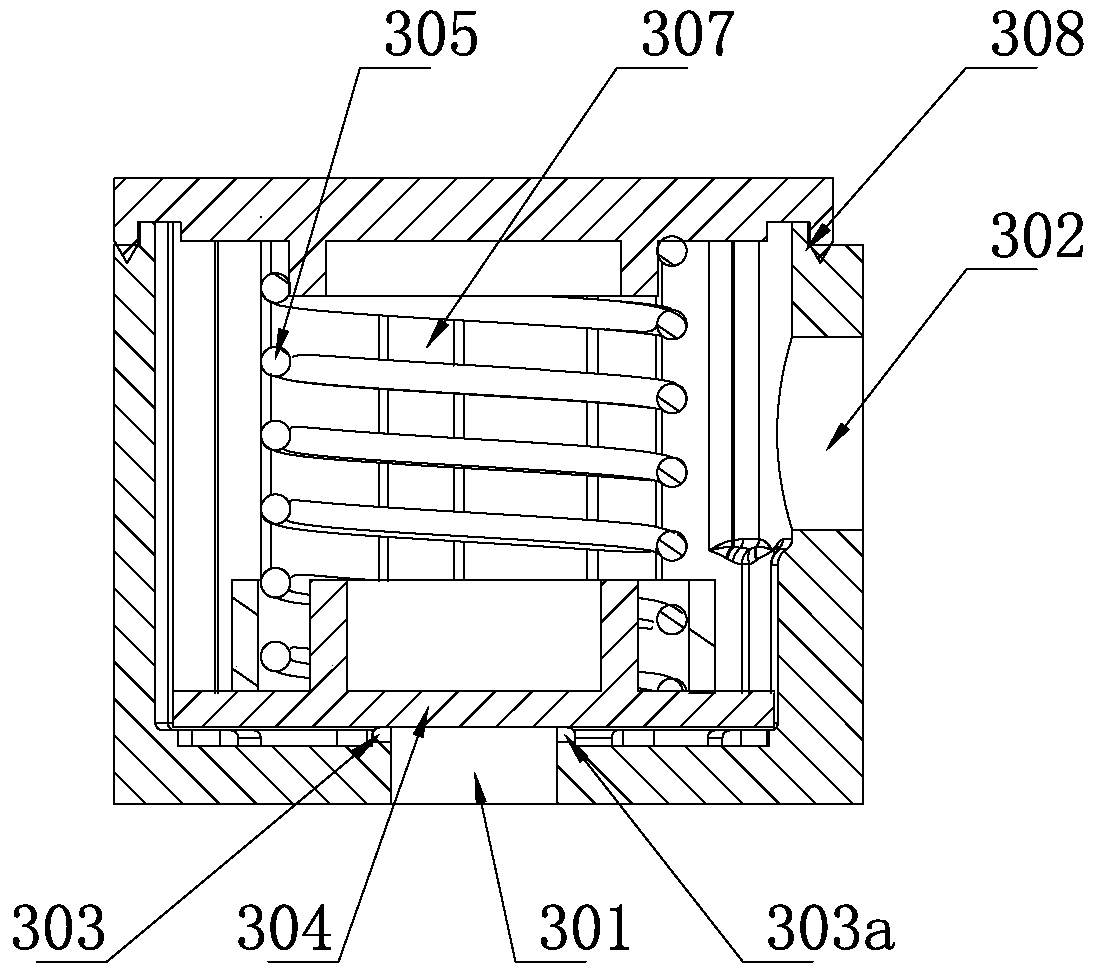

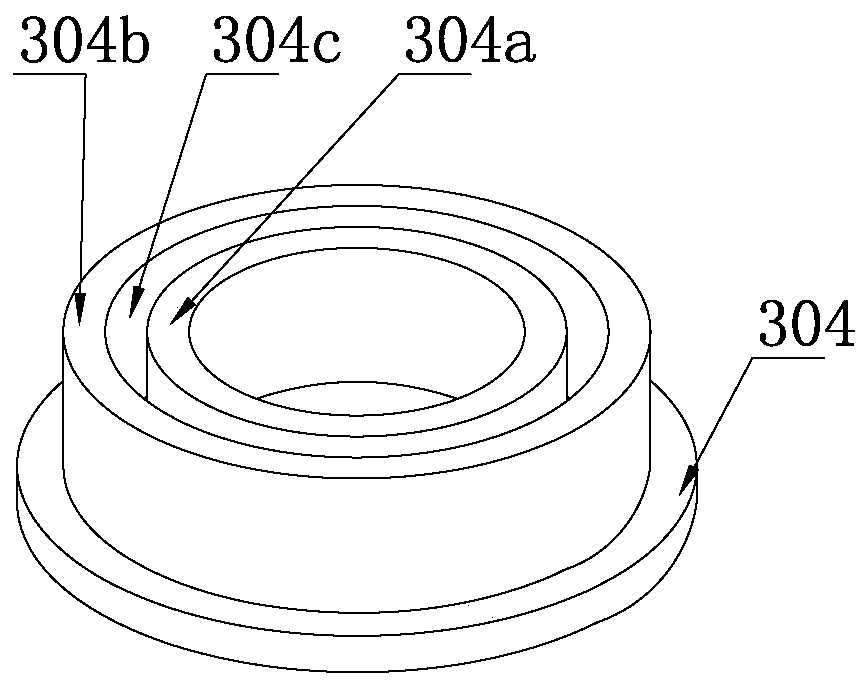

[0025] Such as Figure 1-4 The shown pressure maintaining structure of a GVV valve includes a pressure maintaining cylinder 308 arranged vertically, a cavity is provided inside the pressure maintaining cylinder 308, and an air inlet 301 communicating with the cavity is opened at the bottom of the pressure maintaining cylinder 308. The side of the barrel 308 is provided with an exhaust port 302 that communicates with the cavity. The top edge of the air inlet 301 extends upwards to form a boss 303. Ventilation groove 307, the movable part 304 that can move up and down is provided with in the cavity, and movable part 304 is in order to control the airflow flow between air inlet 301 and exhaust port 302, and movable part 304 is disc-shaped structure, and movable part 304 A spring 305 is arranged between the top wall of the cavity, and the movable part 304 is in contact with the boss 303 through the spring 305, and the disk-shaped movable part 304 realizes the airflow between the a...

Embodiment 2

[0027] Such as Figure 5-7 The shown pressure maintaining structure of a GVV valve includes a pressure maintaining cylinder 308 arranged vertically, a cavity is provided inside the pressure maintaining cylinder 308, and an air inlet 301 communicating with the cavity is opened at the bottom of the pressure maintaining cylinder 308. The side of the barrel 308 is provided with an exhaust port 302 that communicates with the cavity. The top edge of the air inlet 301 extends upwards to form a boss 303. Ventilation groove 307, the movable part 306 that can move up and down is arranged in the cavity, and movable part 306 is in order to control the air flow between air inlet 301 and exhaust port 302, and movable part 306 is cylindrical structure, and cylindrical movable part 306 realizes the air flow control between the air inlet 301 and the exhaust port 302 by its own weight.

Embodiment 3

[0029] Such as Figure 8 A new type of side exhaust GVV valve is shown, including a float 2 arranged in the valve body 1, the top of the valve body 1 is provided with an air inlet 1a, and the top of the valve body 1 extends to the side to form a side exhaust pipe 4 , the side exhaust pipe 4 communicates with the inside of the valve body 1 through the air inlet 1a, the end of the side exhaust pipe 4 is connected with an exhaust port, and the side exhaust pipe 4 is provided with a pressure-holding structure 3; the pressure-holding structure 3 includes a vertical The pressure-holding cylinder 308 arranged vertically, the interior of the pressure-holding cylinder 308 is provided with a cavity, the bottom of the pressure-holding cylinder 308 is provided with an air inlet 301 communicating with the cavity, and the side of the pressure-maintaining cylinder 308 is provided with an exhaust port connected to the cavity. Inlet 302, the top edge of the air inlet 301 extends upwards to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com