Granular material sample equipartition device and sampling system thereof

A granular material and equalizer technology, which is applied in the field of sample equalizer and sampling system, can solve the problems of difficult detection, falling of packaging bag crumbs, etc., and achieve the effect of ensuring reliability and avoiding uneven manual distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

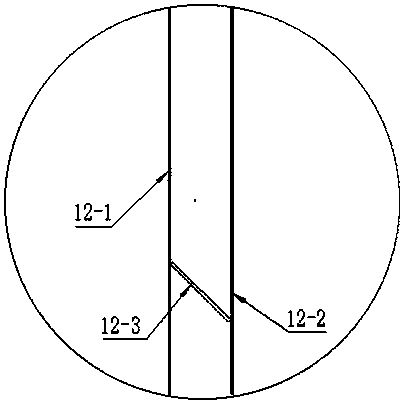

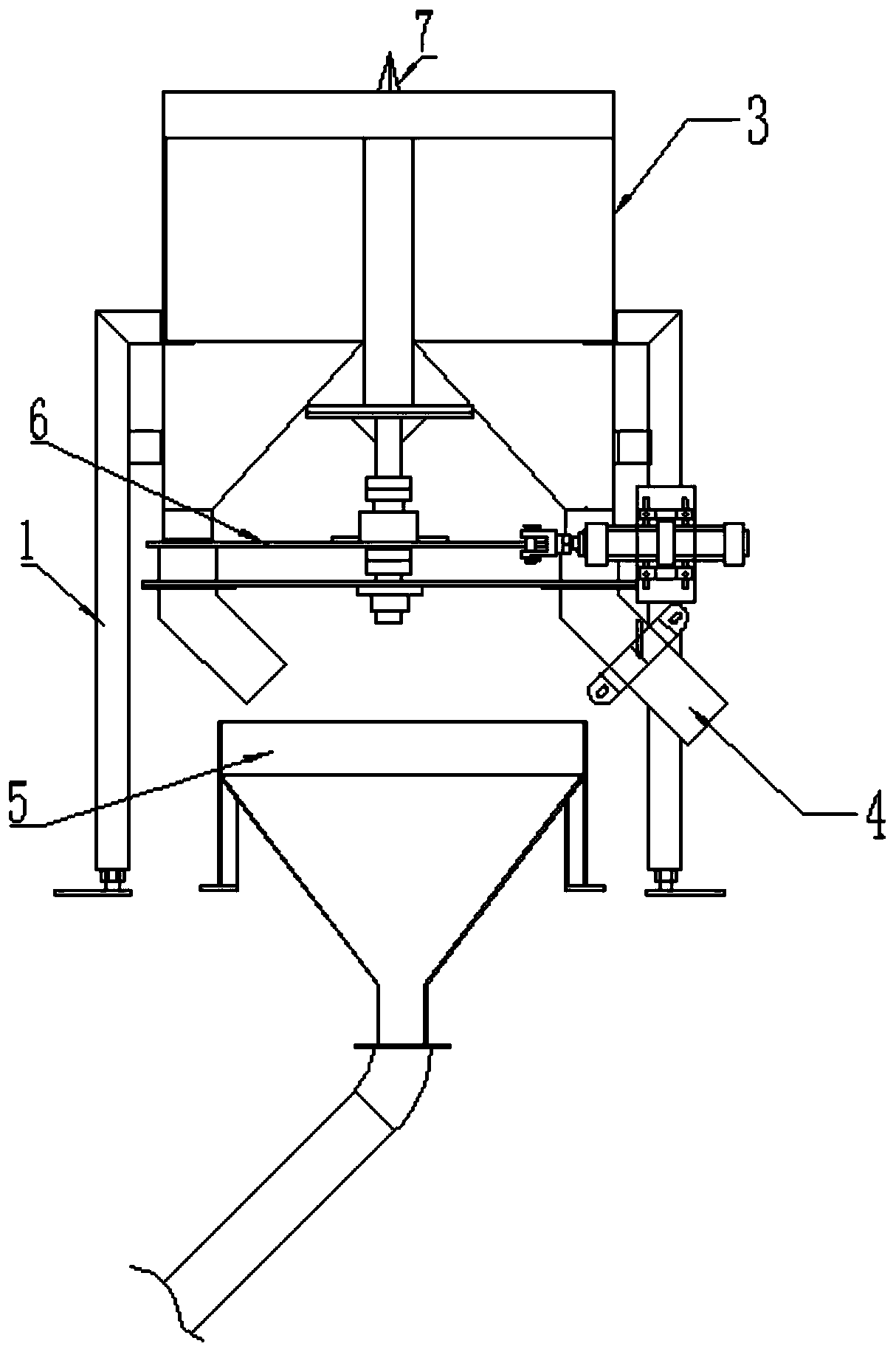

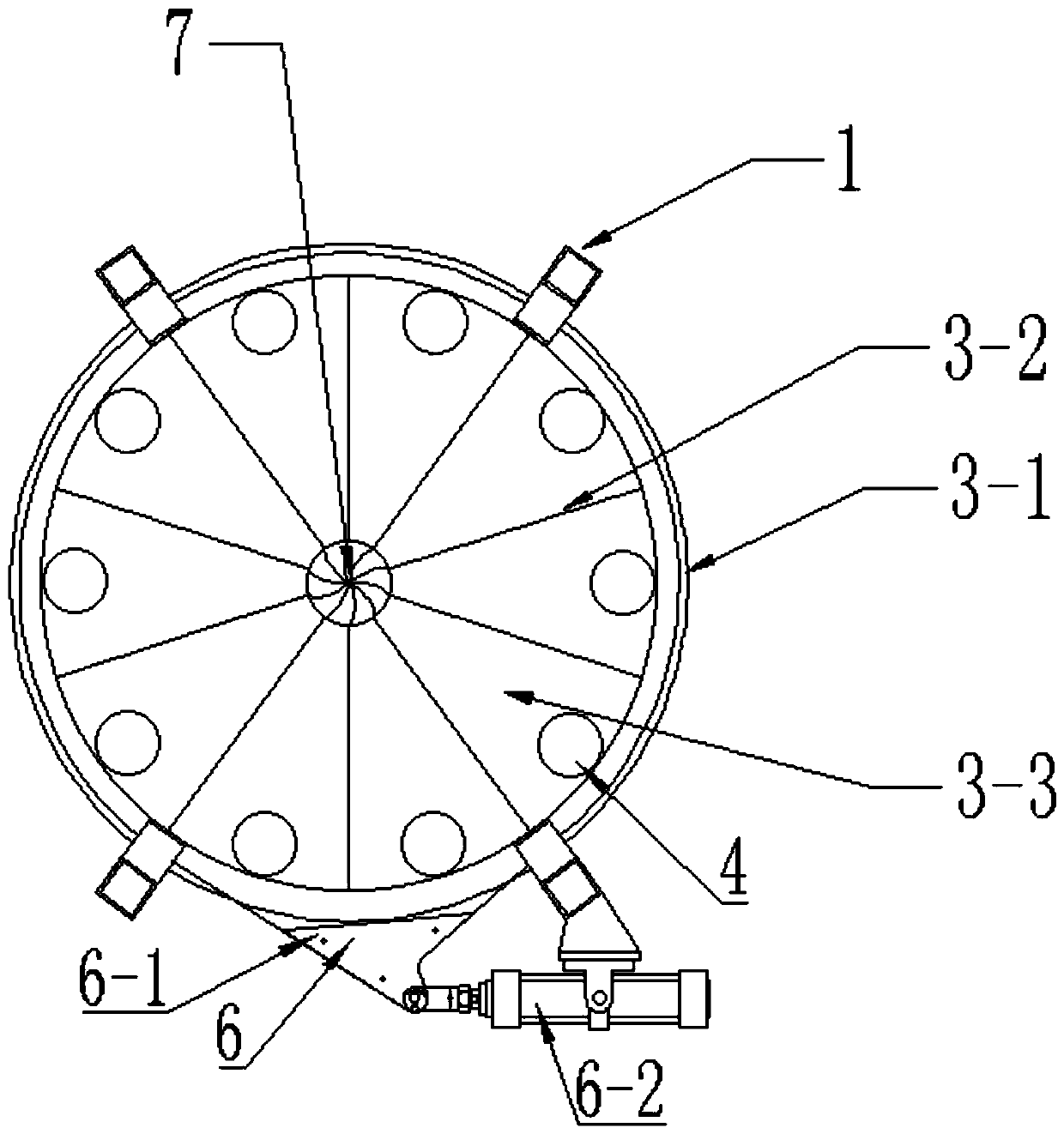

[0051] Such as Figure 1-Figure 5 As shown, a particle material sample equalizer includes an equalizer 3 and an equalizer 7 arranged on the equalizer 3, and the equalizer 7 protrudes from the upper end of the equalizer 3, and It is rotatably arranged at the center of the equalizing bin 3; the equalizing bin 3 is composed of at least two identical sub-bins 3-3.

[0052] The splitting head 7 is a cone 7-1, a plurality of spiral ribs 7-2 are evenly distributed along its circumference on the outer wall of the cone 7-1, and the bottom of the cone 7-1 is provided with a rotating shaft 7 -3, the rotating shaft 7-3 is installed on the equalizing bin 3 through a bearing 7-4.

[0053] The evenly divided warehouse 3 includes a warehouse body shell 3-1 and a warehouse body partition 3-3, and the warehouse body partition 3-3 is evenly distributed along the inner wall of the warehouse body shell 3-1, and the warehouse body shell is 3-1 is divided into a plurality of sub-cabinets 3-3.

[00...

Embodiment 2

[0061] The difference with Example 1 is:

[0062] The dividing head 7 is a sphere.

Embodiment 3

[0064] The difference with Example 1 is:

[0065] The dividing head 7 is a pyramid, and the number of edges of the pyramid is the same as that of the sub-cabinets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com