Production plan dynamic adjustment method for coping with machining sequence change

A production planning and dynamic adjustment technology, applied in program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of tedious calculation, time-consuming, error-prone, etc., to improve the use efficiency, facilitate subsequent changes, and avoid sharp time spans. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

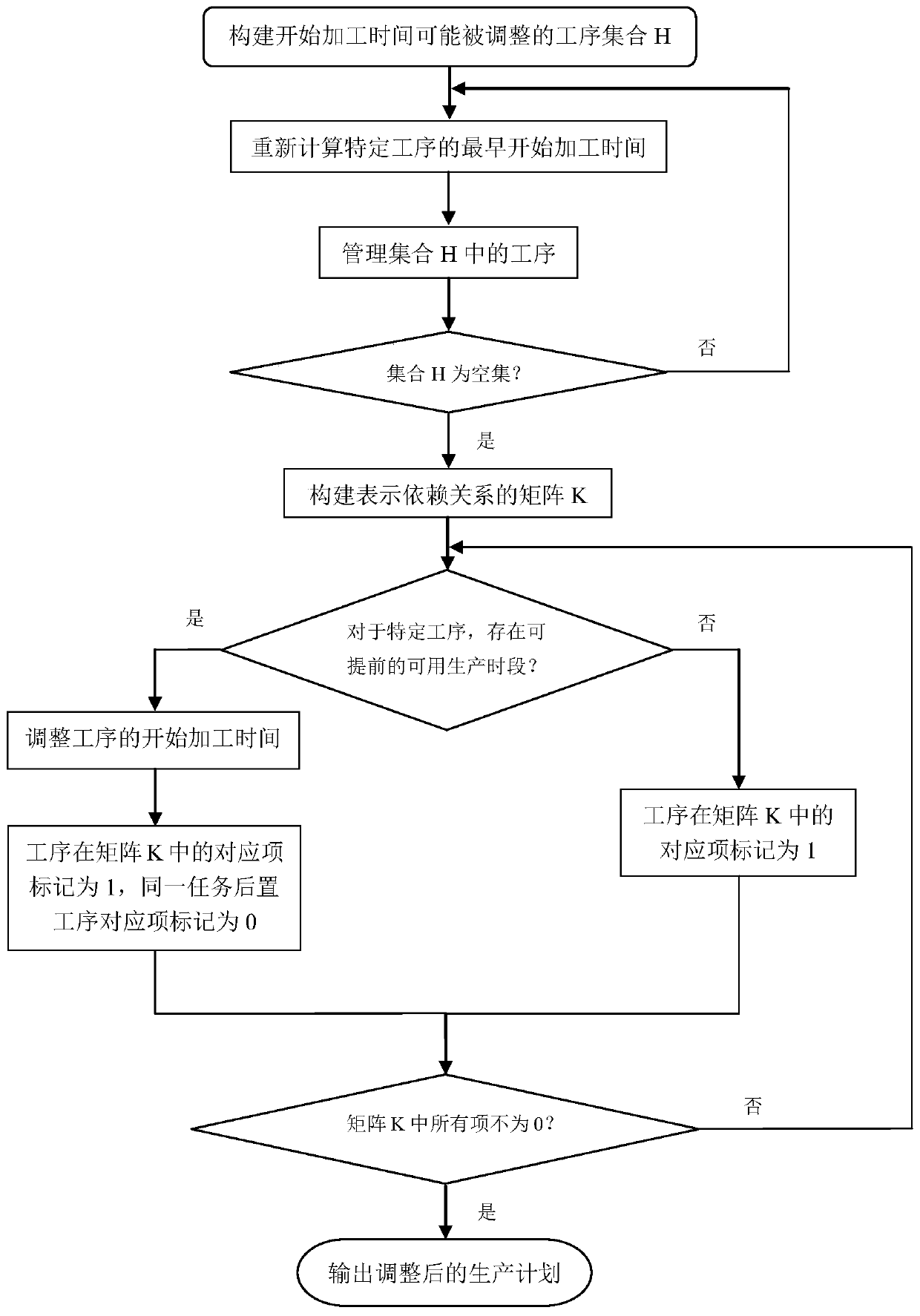

[0026] A method for dynamic adjustment of production plan in response to changes in processing order, such as figure 1 shown, including the following steps:

[0027] S1. Identify all processes whose processing sequence is delayed and add them all to the process set H whose start processing time may be adjusted;

[0028] S2. For each process in the set H, its start processing time depends on the end time of the previous process of the assigned task and the end time of the previous process of the allocated machine, and recalculate the earliest start processing time as the process according to this dependency The new start processing time of , delete the process from the set H; if the new start processing time of the process is greater than the original start processing time, then add the process whose start processing time is affected to the set H;

[0029] The process whose start processing time is affected includes the next process of the machine assigned to the start process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com