Insulating layer coating device for wires and cables

A coating device, wire and cable technology, applied in the direction of conductor/cable insulation, conductor/cable supply device, cable/conductor manufacturing, etc., can solve the problem that the insulating cloth cannot be evenly wound, the insulating cloth is inconvenient to replace, and the covering efficiency is affected and other problems, to achieve better coating effect, convenient coating, and avoid the effect of being worn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

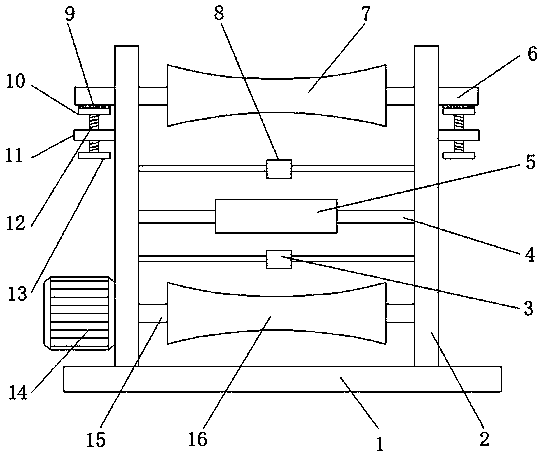

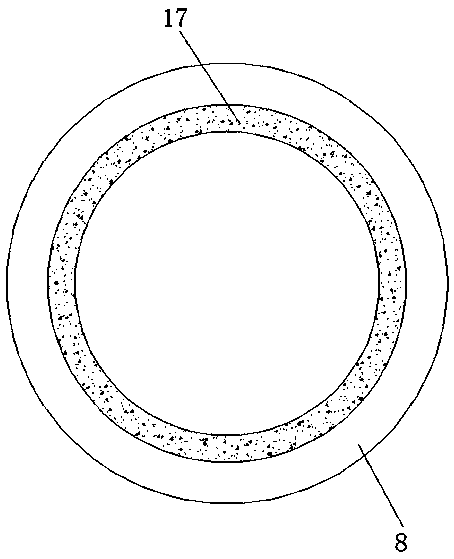

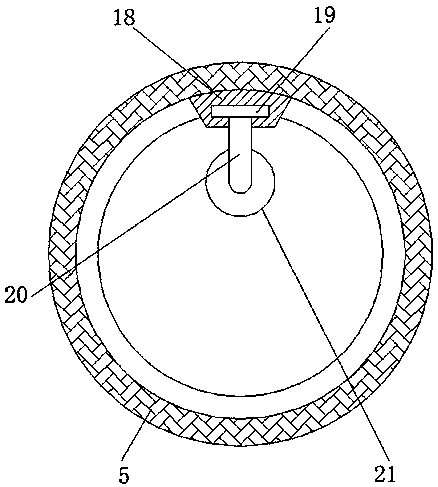

[0029] refer to Figure 1-4 , an insulating layer coating device for wires and cables, comprising a base plate 1, a vertical plate 2 is welded on the top outer wall of the bottom plate 1 near both sides, and a motor 14 is connected to the outer wall of one side of the vertical plate 2 through bolts, and the motor 14 One end of the output shaft is provided with a rotating shaft 15, and the outer wall of the rotating shaft 15 is provided with a winding roller 16, and one side outer wall of the vertical plate 2 has a mounting hole, and the inwall of the mounting hole is connected with a rotating rod 6 through a bearing rotation, and the rotating rod 6 The outer wall is provided with a pay-off roller 7, and the outer wall of one side of the vertical plate 2 is welded with a connecting rod 4, and the outer wall of one end of the connecting rod 4 is connected with an electric slide rail 5 through a bolt, and the inner wall of the electric slide rail 5 is slidably connected with a sli...

Embodiment 2

[0033] refer to Figure 5 , an insulating layer coating device for wires and cables. Compared with Embodiment 1, this embodiment also includes that the four corners of the bottom outer wall of the bottom plate 1 are welded with supporting legs, and the bottom outer walls of the supporting legs are connected by bolts. 22 to the wheel.

[0034] Working principle: when in use, the universal wheel 22 located at the bottom of the bottom plate 1 facilitates the movement of the device and makes the use more flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com