Automatic battery replacement system and method for mobile equipment

A mobile device, automatic replacement technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of reduced work efficiency, long charging time, and prolonged investment payback period of robots, so as to improve sustainable working time, Increase work efficiency and ensure the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0034] Mobile devices refer to mechanisms and devices that are powered by batteries and can be moved. Common mobile devices include various mobile robots, such as sweeping robots, logistics robots, etc. Robots are used as examples for illustration below.

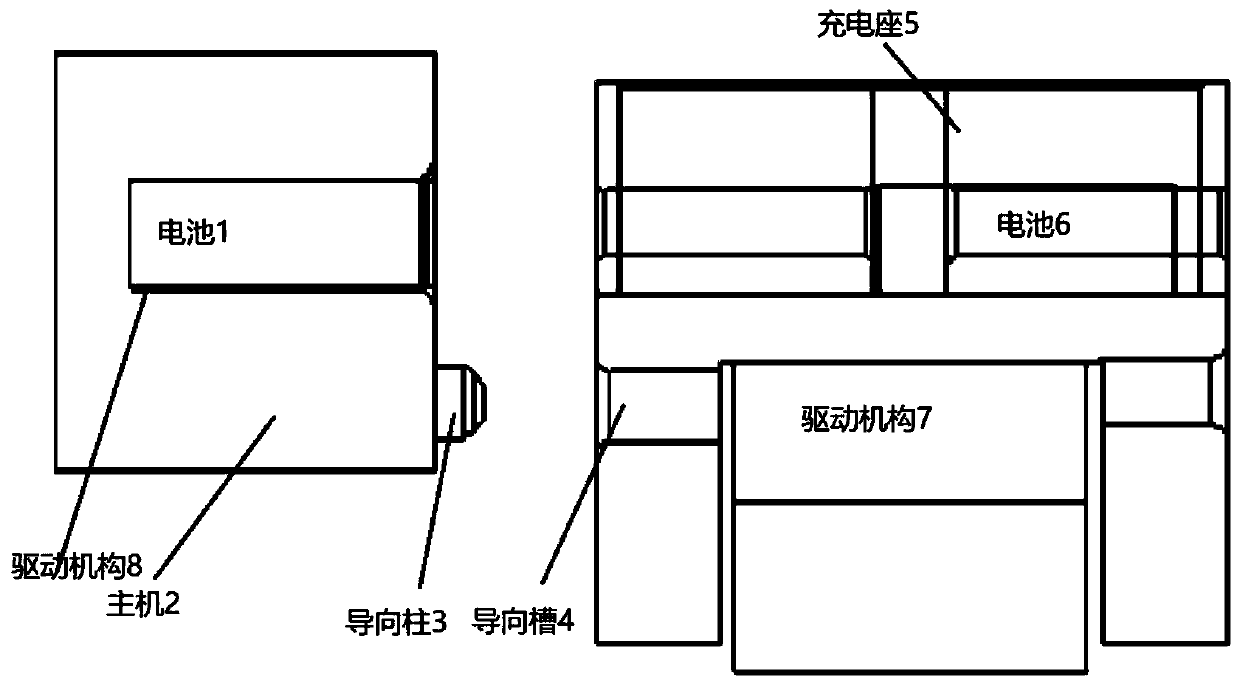

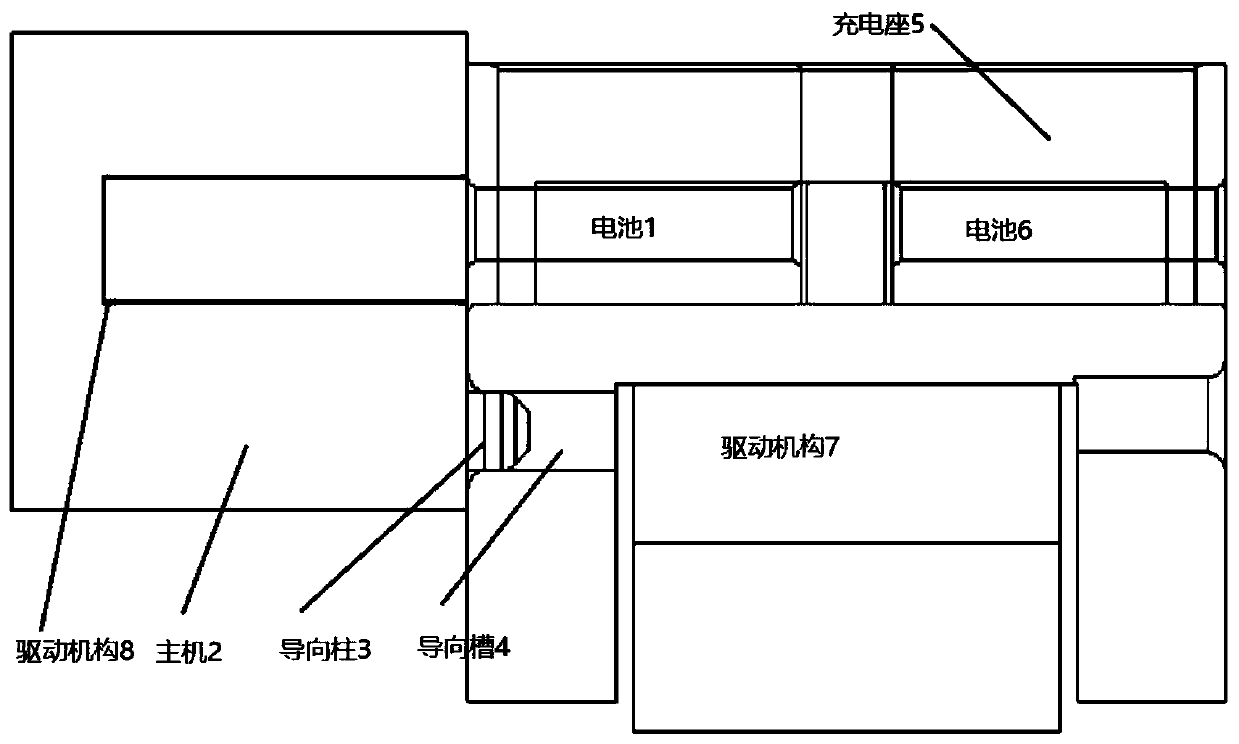

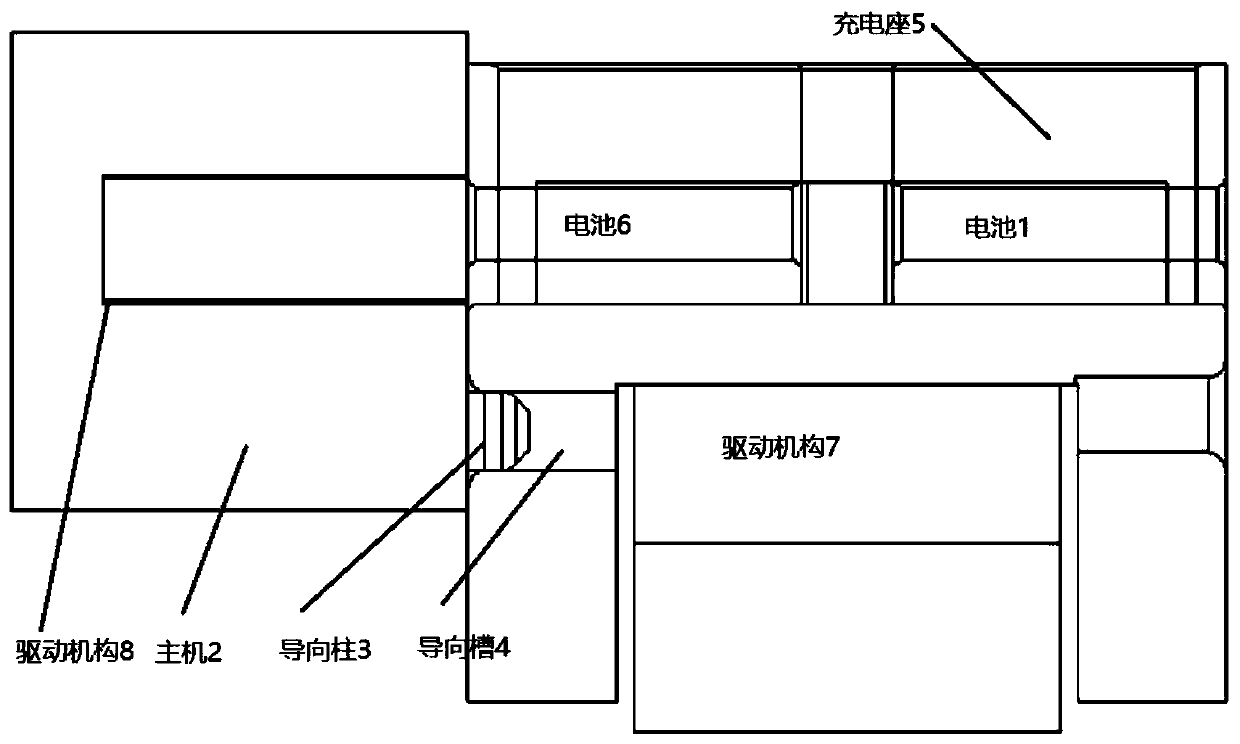

[0035] Such as figure 1 As shown, an automatic battery replacement system for a mobile robot includes a robot body 2, a battery compartment of the robot is arranged on the robot body 2, a battery 1 of the robot is arranged in the battery compartment, and the first battery 1 is detachably arranged on the robot body 2 in the battery compartment, supplying power for the work of the robot. Its power supply mode realizes detachable power supply in a plug-in manner. A first driving mechanism 8 is arranged in the robot body 2, and the first dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com