Urea production process and production plant using co2 produced by oxy-combustion

A technology of oxygen-enriched combustion and production process, which is used in products, preparation of urea derivatives, chemical instruments and methods, etc., can solve the problem of inability to supply a variety of supplies, and achieve the effects of simplifying capture, increasing efficiency, and improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

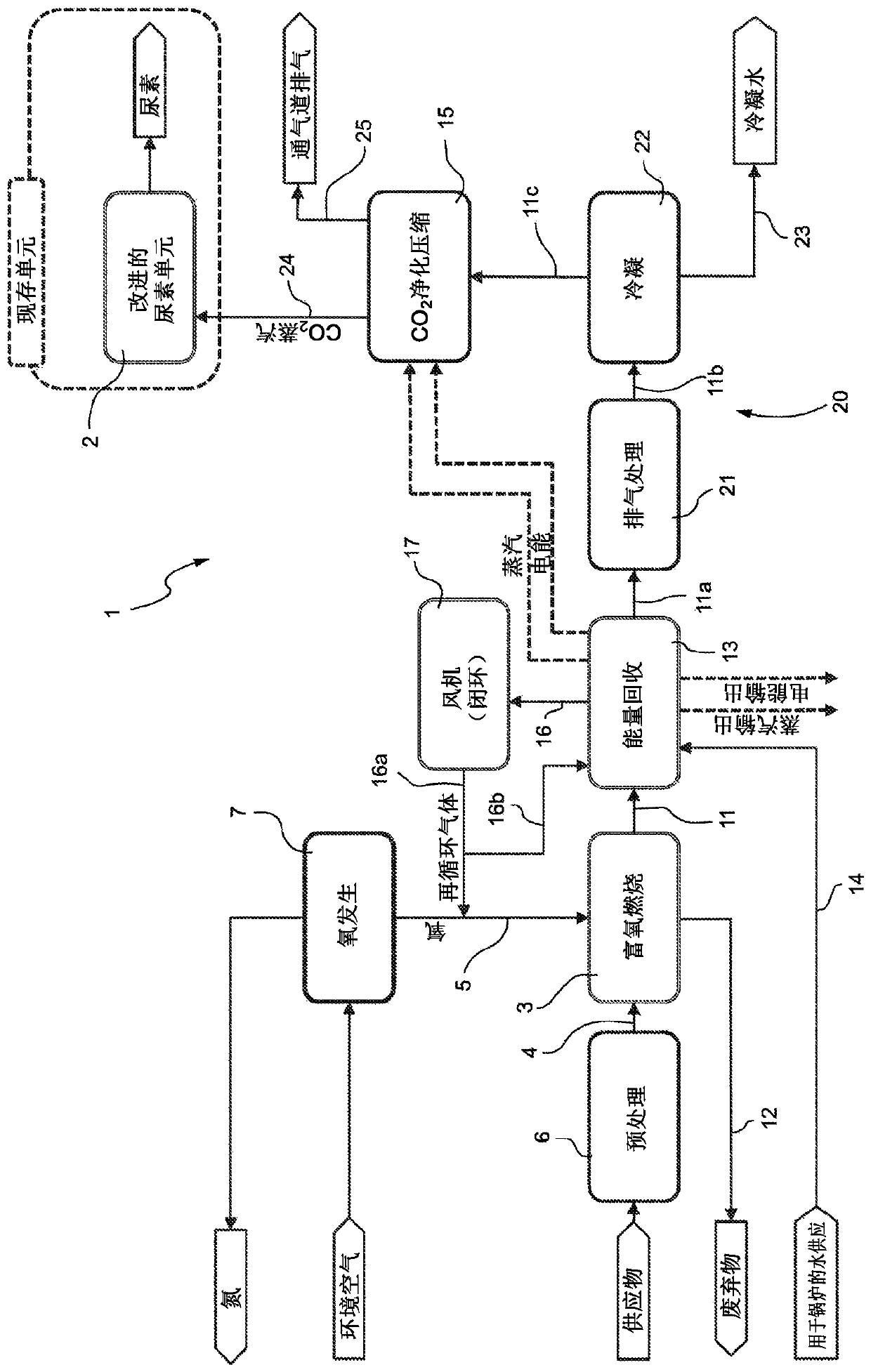

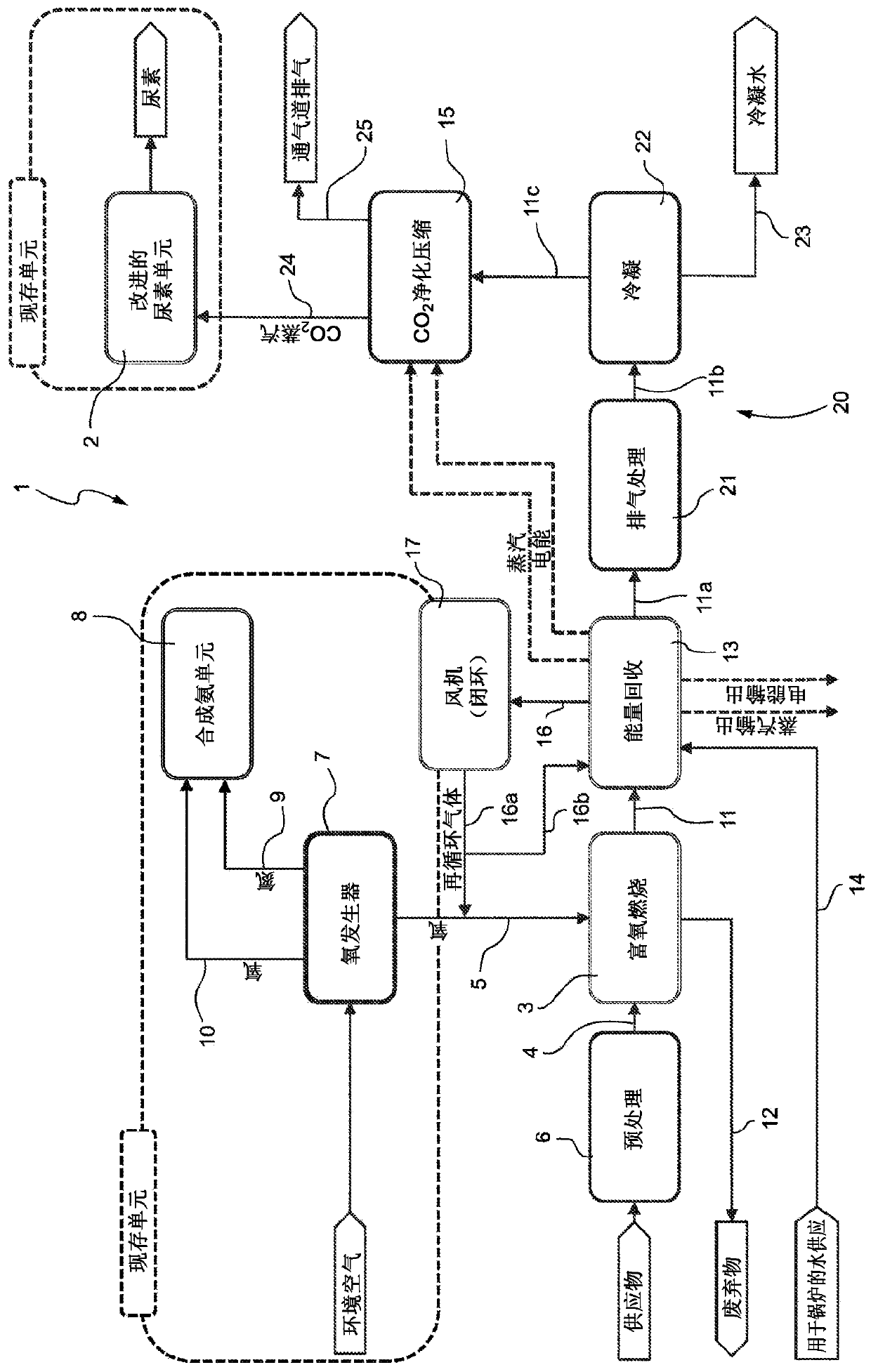

[0044] exist figure 1 Among them, 1 represents the urea production plant as a whole, which includes a urea unit 2, which is used to produce urea through the reaction of ammonia and carbon dioxide, and an oxygen-enriched combustion unit 3, which converts the carbon dioxide (CO2) produced in this unit 2 ) to the urea unit 2 for supplying feedstock to the urea synthesis reaction of ammonia and carbon dioxide.

[0045] The urea unit 2 (which can also be an existing unit, “enhanced” with the integration of the oxyfuel unit 3 ) is basically known per se and is therefore not described or shown in detail for the sake of simplicity.

[0046] The urea unit 2 in which the urea production process takes place can be of various types.

[0047] For example, but not necessarily, the urea unit 2 may be configured to take place in a conventional urea process known as the "SnamprogettiTM Urea Technology", but it should be understood that the invention is also applicable to other urea production...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap