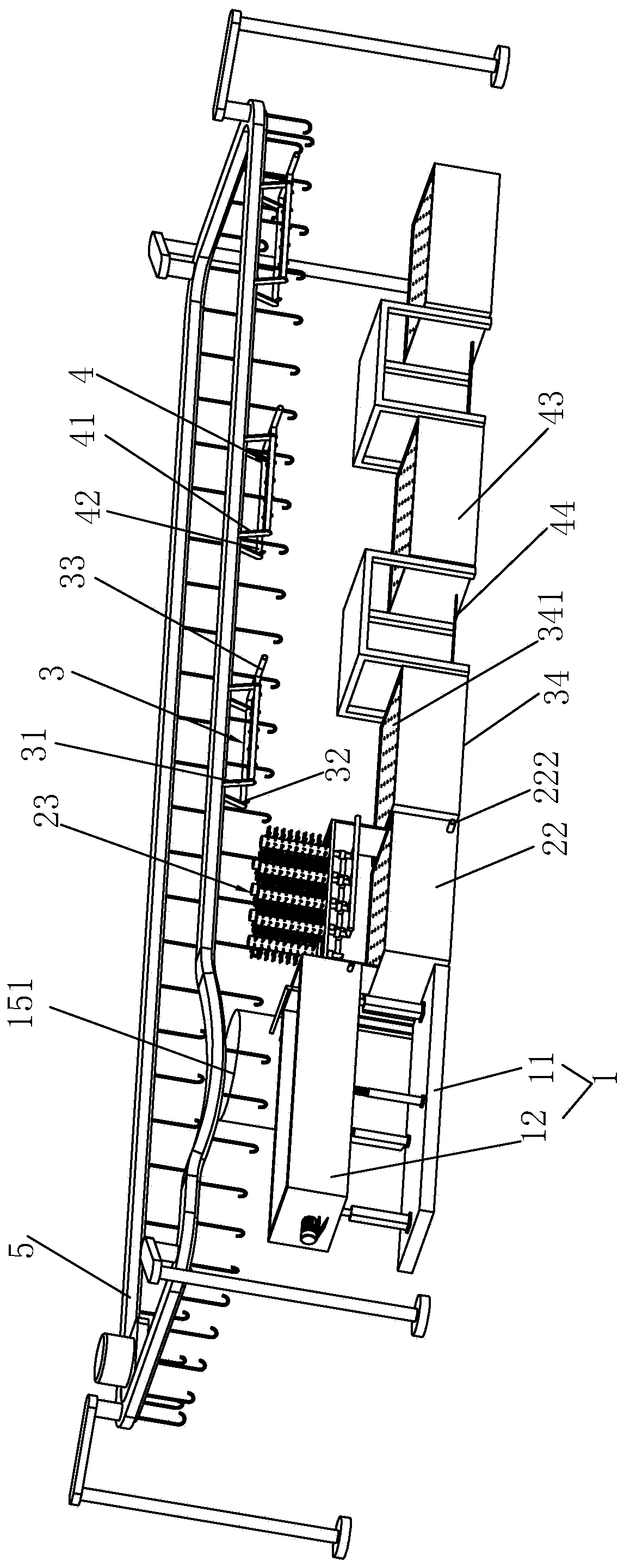

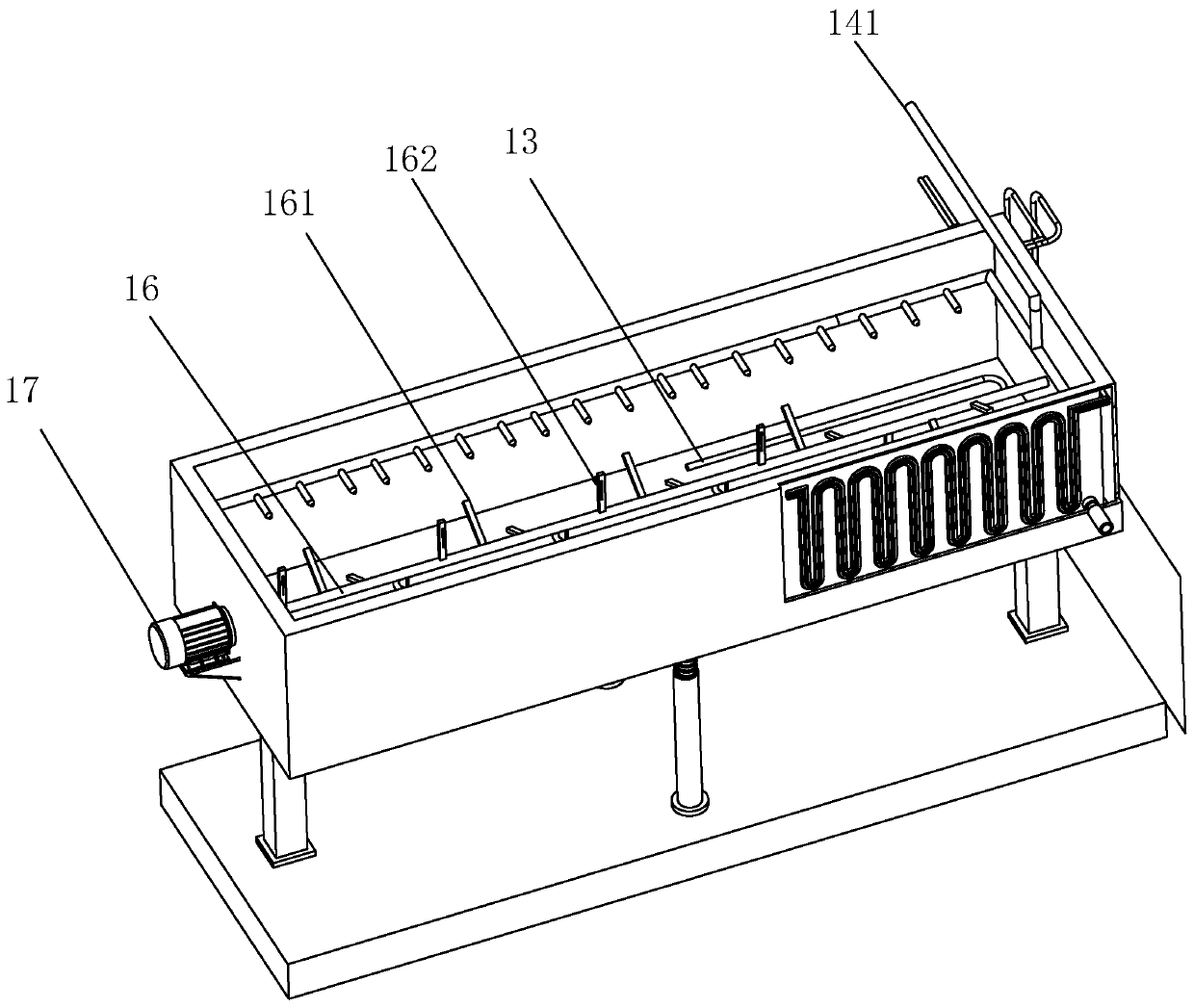

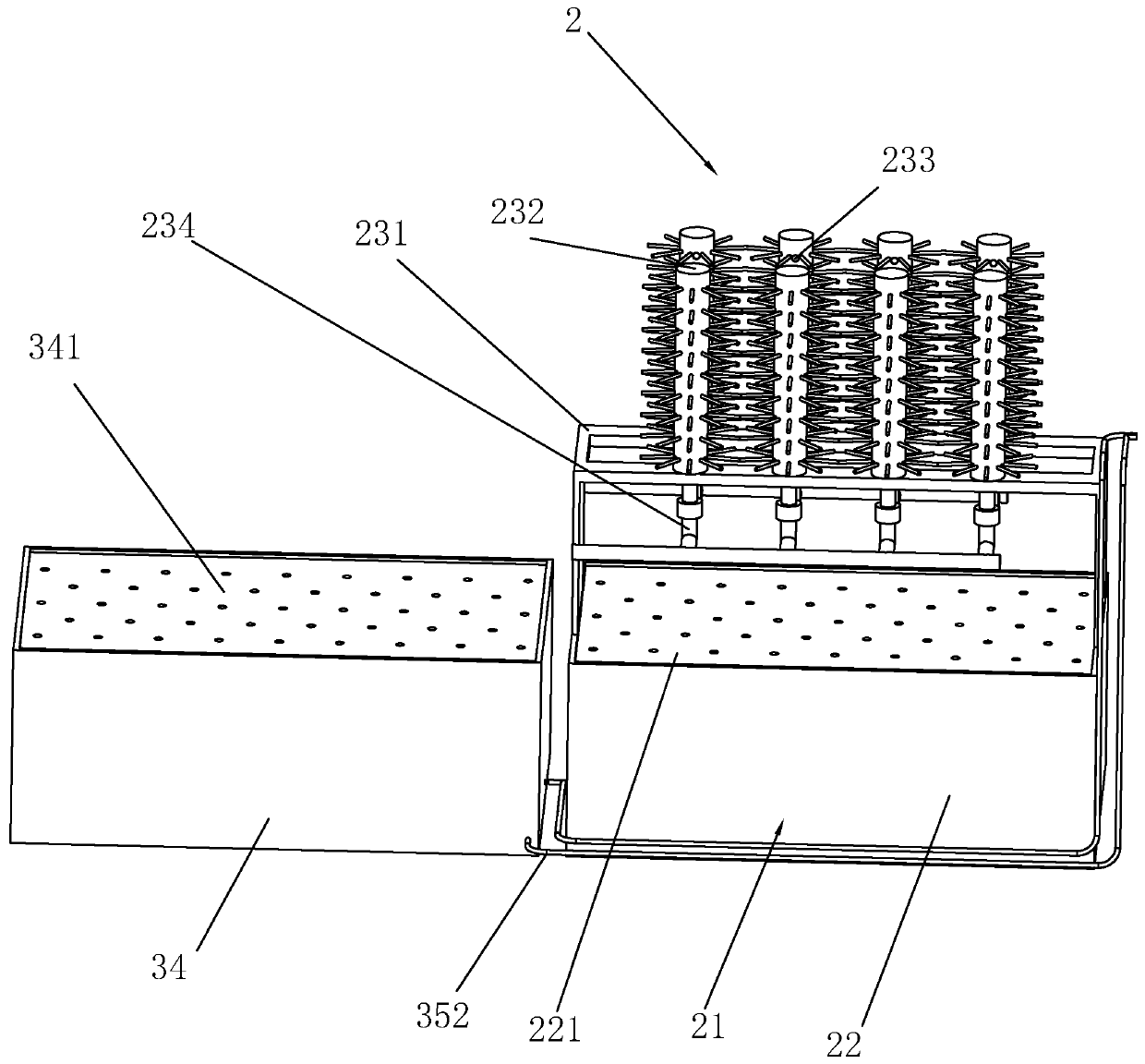

Production technology and equipment system for broiler slaughtering and cutting

A technology of slaughtering and segmentation and production technology, which is applied in the direction of slaughtering, dividing poultry, and processing meat, etc. It can solve problems such as uneven soaking, skin damage, and difficult to clean, so as to shorten the time of scalding, facilitate hair removal, and save procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A production process for slaughtering and dividing broilers, comprising the steps of:

[0048] Step 1: Pre-treatment of live chickens, hang the chickens upside down, bleed and drain the blood, and set aside; the operation of hanging the chickens is to grasp the hock joints of the chickens, hold the chicken wings to grab the chickens out of the cage, and then grab the right sides of the chickens with the left hand Legs, the right hand grasps the left leg of the chicken, aim at the hook to hang the chicken, and hang it firmly, with gentle movements to reduce screaming and damage; before the live chicken is bled, hang it upside down in a dark room to keep the live chicken quiet. Gently hold the chicken head, cut off the left neck artery and vein, and do not injure the trachea and esophagus; after the bloodletting is completed, drain the blood in the dark room for 5 minutes to achieve sufficient bloodletting.

[0049] Step 2: The chicken treated in step 1 is scalded in wate...

Embodiment 2-9

[0059] The difference between embodiment 2-9 and embodiment 1 lies in the difference of processing parameters.

[0060] The processing parameter of table 1 embodiment 1-9

[0061]

[0062]

[0063] detection

[0064] 1. The plucking rate of the chicken carcass is controlled at 5%, the remaining rate of hair roots is controlled at 2%, and the leg hair is controlled at 25%.

[0065] The detection result of table 2 embodiment 1-9

[0066]

[0067] It can be drawn from Table 2 that the hair removal effects of the chickens processed under the process parameters of Examples 1-9 are all better and meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com