Shaping method of titanium alloy medical inner fixing plate

A fixed plate and titanium alloy technology, applied in the field of medical devices, can solve the problems of low fitting accuracy of target bone tissue, material waste, and unpredictable bending shape information of the titanium alloy internal fixation plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures. The technical solution of the present invention is further explained by taking the mandible as an example. .

[0067] The shaping method of the titanium alloy medical internal fixation plate provided in this embodiment comprises the following steps:

[0068]Step 1: Obtain the corresponding unbent titanium alloy initial shape of the mandible and the existing 3D virtual model of the mandible of the target patient.

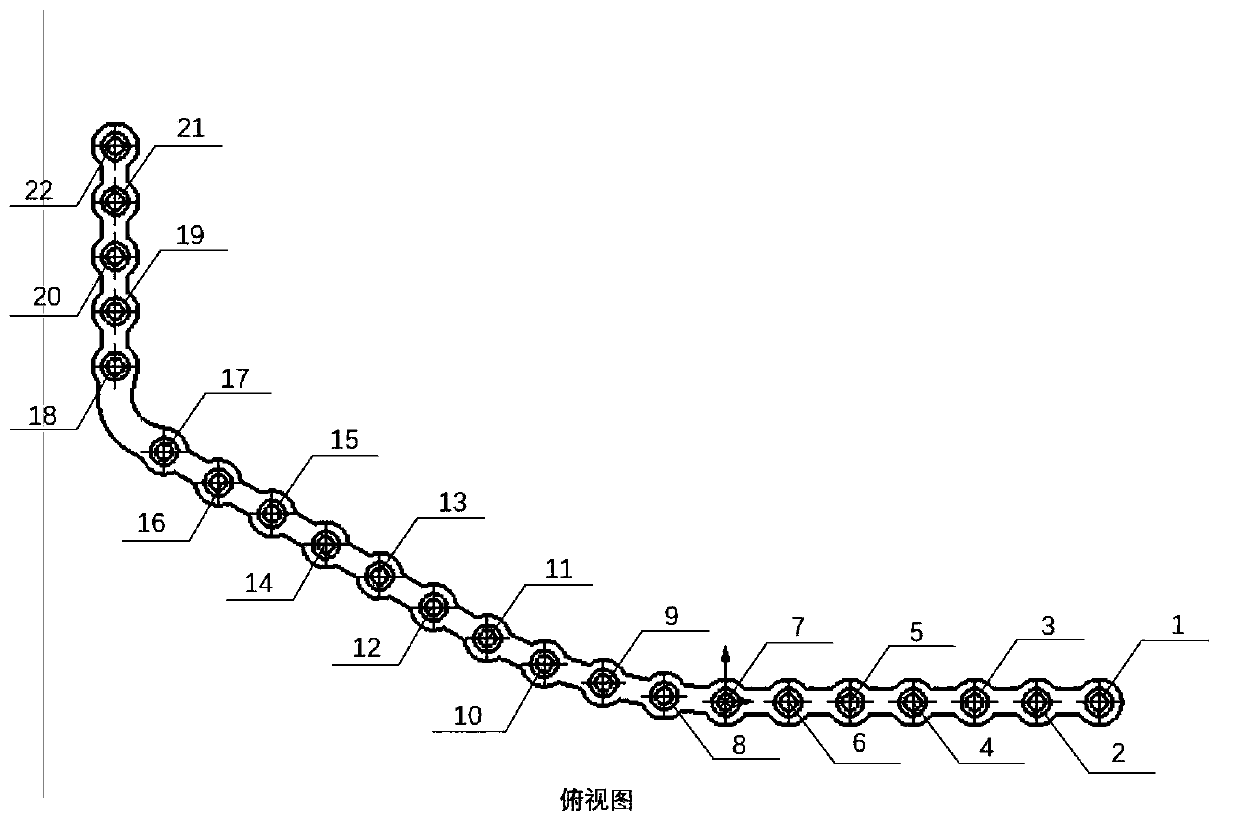

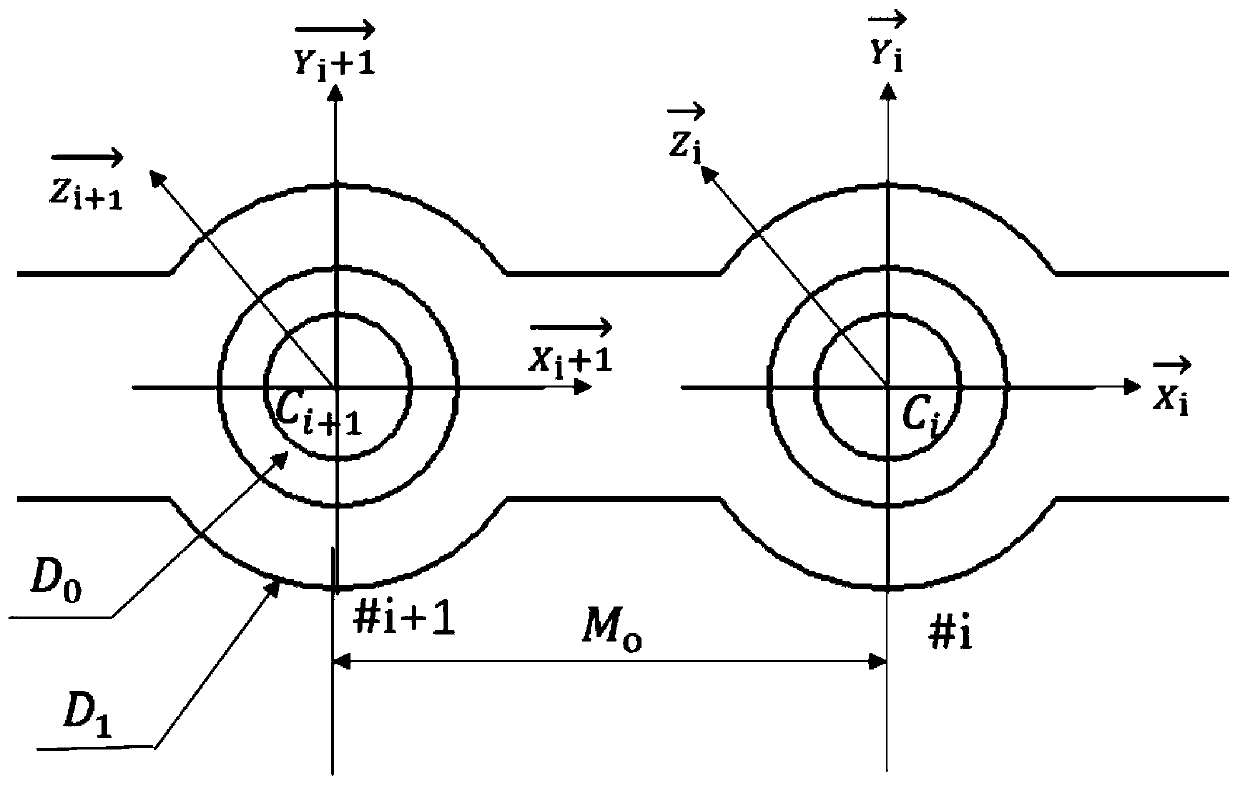

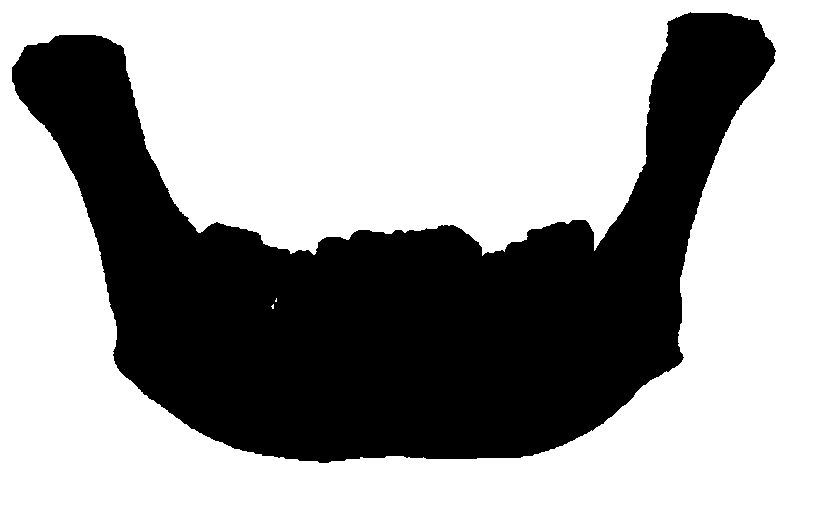

[0069] Such as figure 1 , 2 The unbent titanium alloy initial shape figure corresponding to the mandible shown is a known standard shape, and the labels 1-22 in the figure represent the 1st to 22nd bending discs respectively; image 3 , 4 Shown is the existing three-dimensional virtual model of the mandible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com