Polishing and deburring device for side wall of metal short pipe

A short tube and metal technology, which is applied in the field of metal short tube side wall grinding and deburring devices, can solve the problems of low grinding efficiency, achieve high-efficiency dust removal, and environmental protection in the deburring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

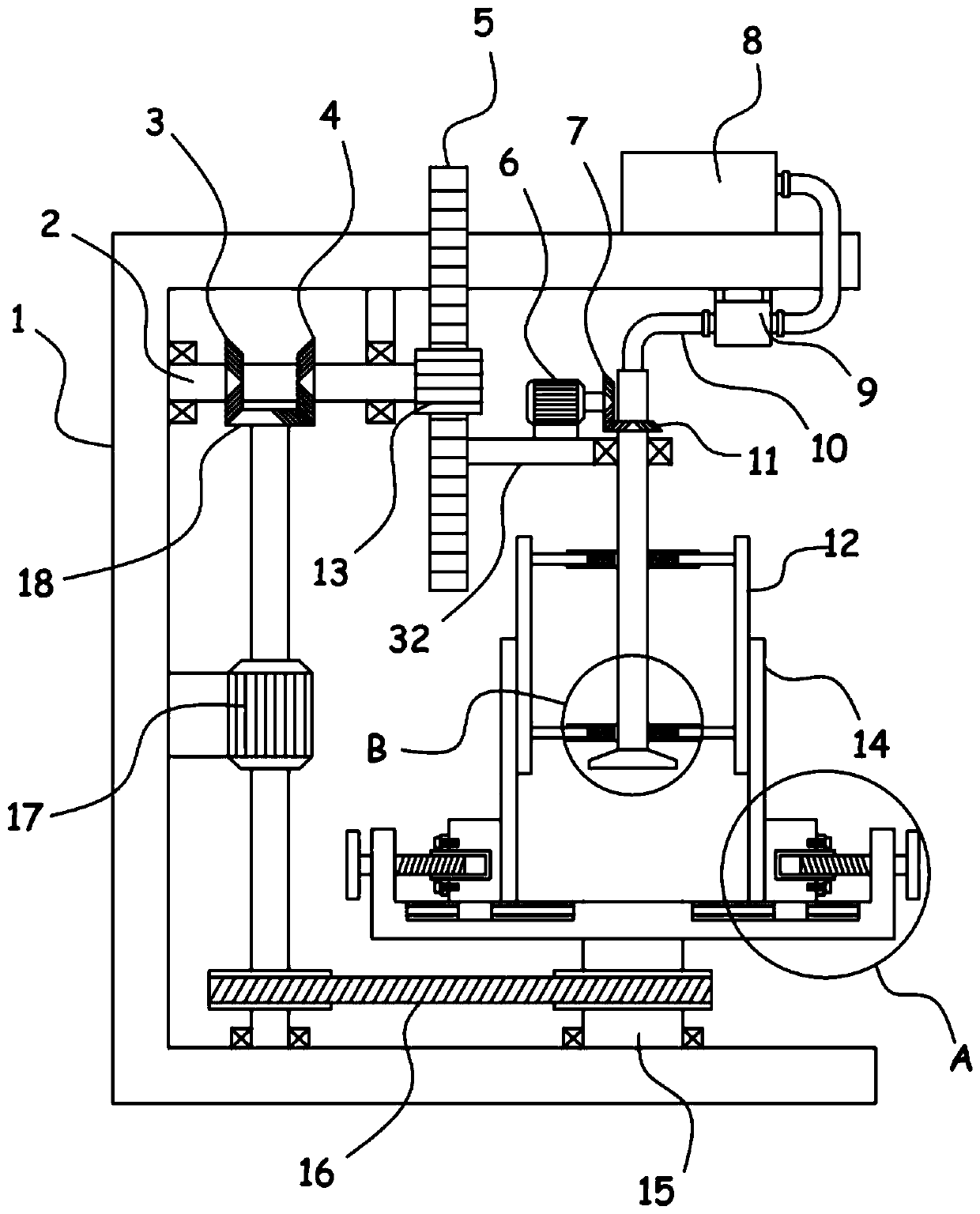

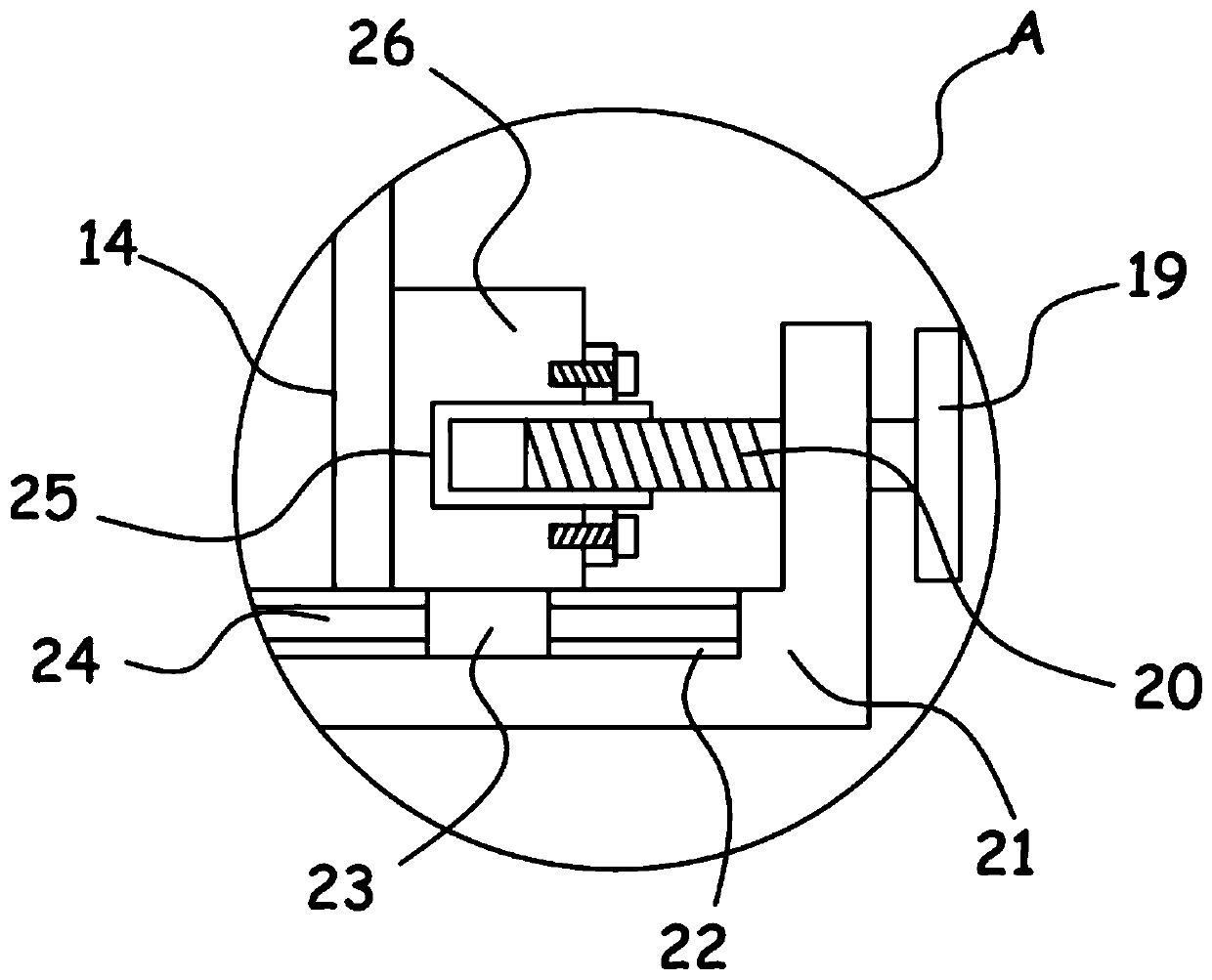

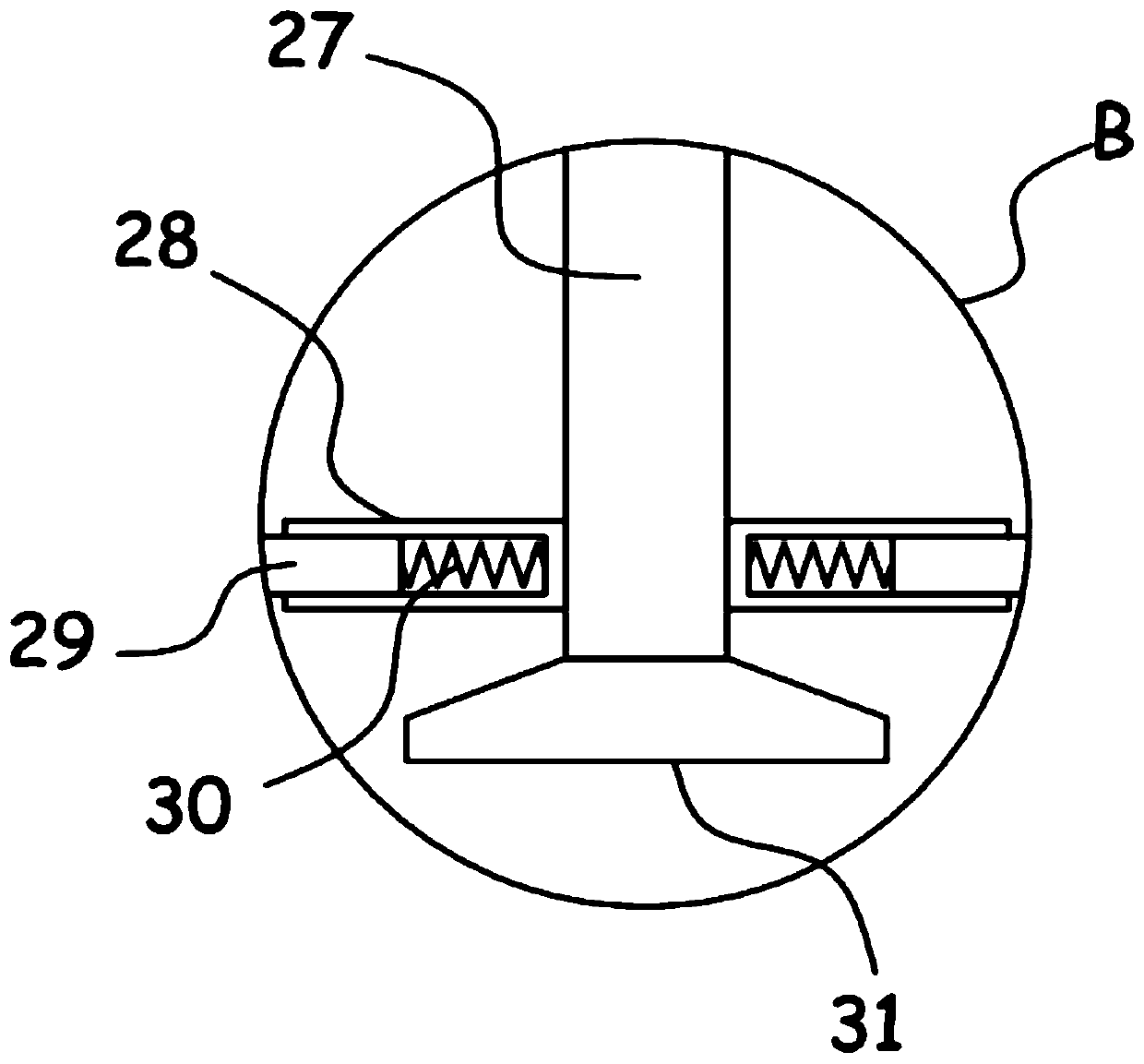

[0025] see Figure 1-4 , a metal short pipe side wall grinding and deburring device, comprising a support frame 1, a rotating shaft 15 is installed on the support frame 1, a support frame 21 is coaxially fixed on the upper end of the rotating shaft 15, and a support frame 21 is provided on the support frame 21 for metal The short tube 14 clamps a fixed clamping mechanism, and the support frame 1 is driven and connected with a horizontal plate 32 arranged horizontally through a lifting mechanism, and a servo motor 6 is fixed on the horizontal plate 32, and the servo motor 6 is driven and connected with a The grinding slat 12 attached to the inner wall of the metal short pipe 14, the top of the support frame 1 is fixed with a dust collection box 8, and the short metal pipe 14 is provided with a dust suction mechanism communicating with the dust collection box 8.

[0026] The device supports the metal short pipe 14 through the supporting frame 21 provided, and the clamping mechan...

Embodiment 2

[0032] On the basis of Embodiment 1, in addition, the elevating mechanism includes a straight toothed rack 5 fixed vertically with the horizontal plate 32, a transmission gear 13 is meshed and connected to the straight toothed rack 5, and a driven gear 13 is coaxially fixed on the transmission gear 13. Axis 2, a biaxial motor 17 is fixed on the support frame 1, an output shaft of the biaxial motor 17 is coaxially fixed with an incomplete bevel gear 18, and the incomplete bevel gear 18 is alternately meshed and connected with a sleeve fixed on the driven shaft 2 The driven bevel gear I3 and the driven bevel gear II4.

[0033] The double-axis motor 17 can drive the rotation of the incomplete bevel gear 18, and the incomplete bevel gear 18 is alternately meshed with the driven bevel gear I3 and the driven bevel gear II4, so that the driven shaft 2 can drive the transmission gear 13 to perform forward and reverse alternately. , and then realized that the straight rack 5 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com