Annular inclined perforating machine

A punching machine, ring-shaped technology, applied in mechanical equipment, sugarcane machining, fixed drilling machines, etc., can solve the problems of uneven depth, inclination, inconvenient processing, poor product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the accompanying drawings and preferred embodiments, a detailed description of the specific implementation, structure, features and effects of the present invention is as follows.

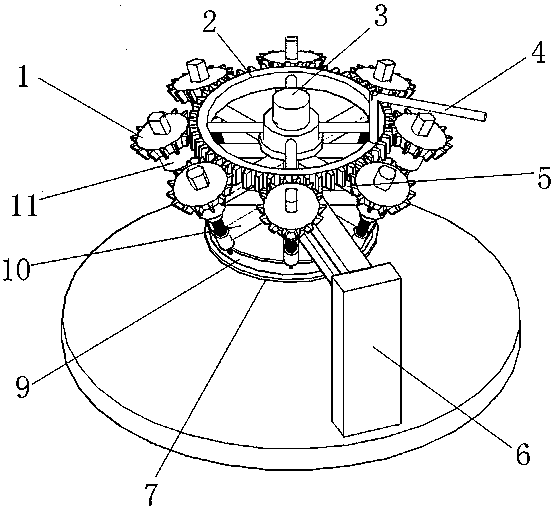

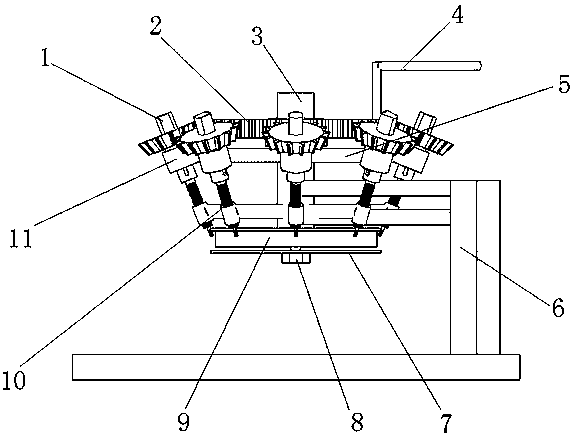

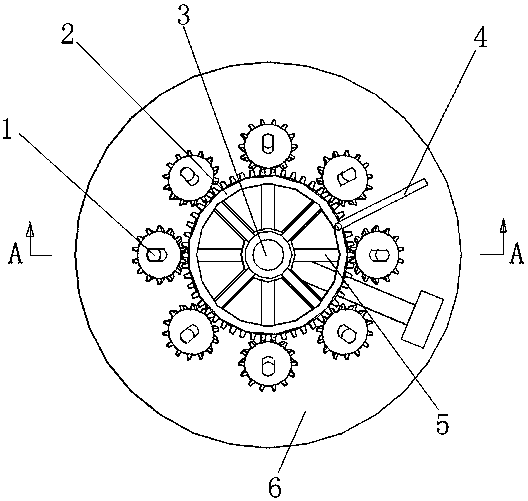

[0026] A kind of annular inclined punching machine of the present invention is characterized in that: several inclined rotary drill bits 1 are installed around the gear A2, the upper ends of several rotary drill bits 1 are inserted into several rotary sleeves 11, and several rotary sleeves 11 are fixedly connected to one end of connecting bar A5 , the other end of the connecting bar A5 is fixedly connected to the shaft A3, the upper end of the shaft A3 is connected to the gear A2 through a bearing, the lower end is fixedly connected to the positioning seat 9, one end of the connecting bar B10 respectively, the other end of the connecting bar B10 is fixedly connected to the lower end of the rotary drill bit 1, and the middle part of the shaft A3 is arranged below Posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com