Automatic loading and unloading robot for parts processing

A technology of automatic loading and unloading, parts processing, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor scalability, waste of space in the center and corner of the workshop, and the direction of the turntable is not adjustable, and achieves ingenious design and firm clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

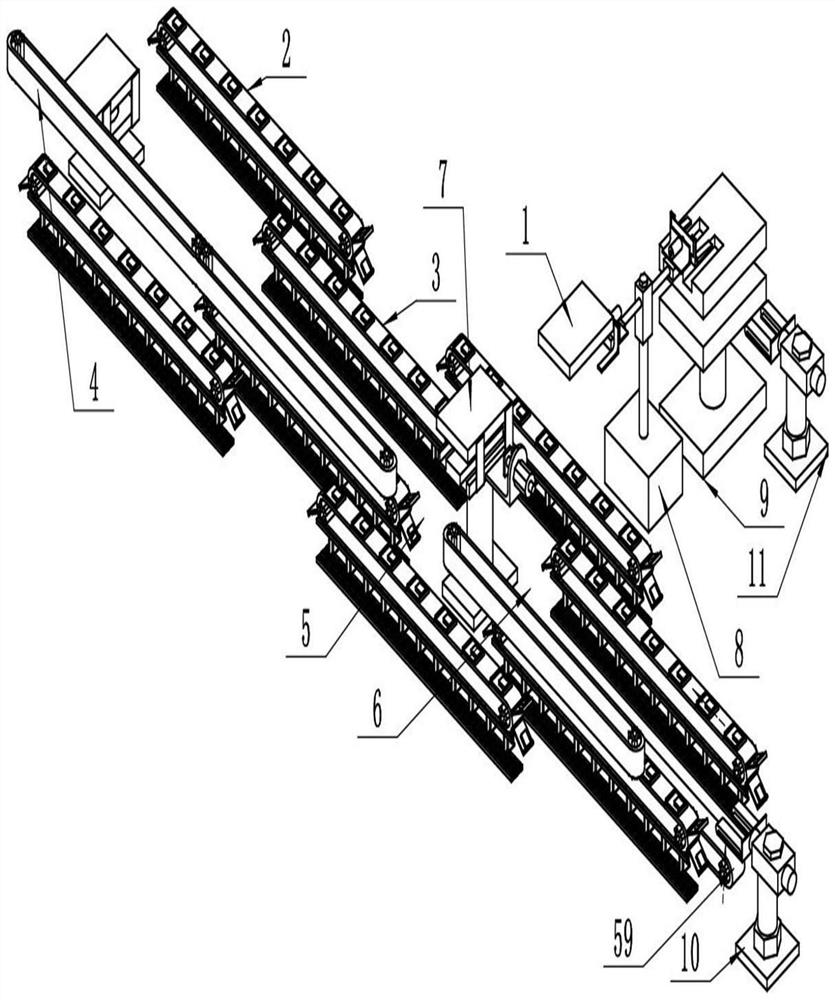

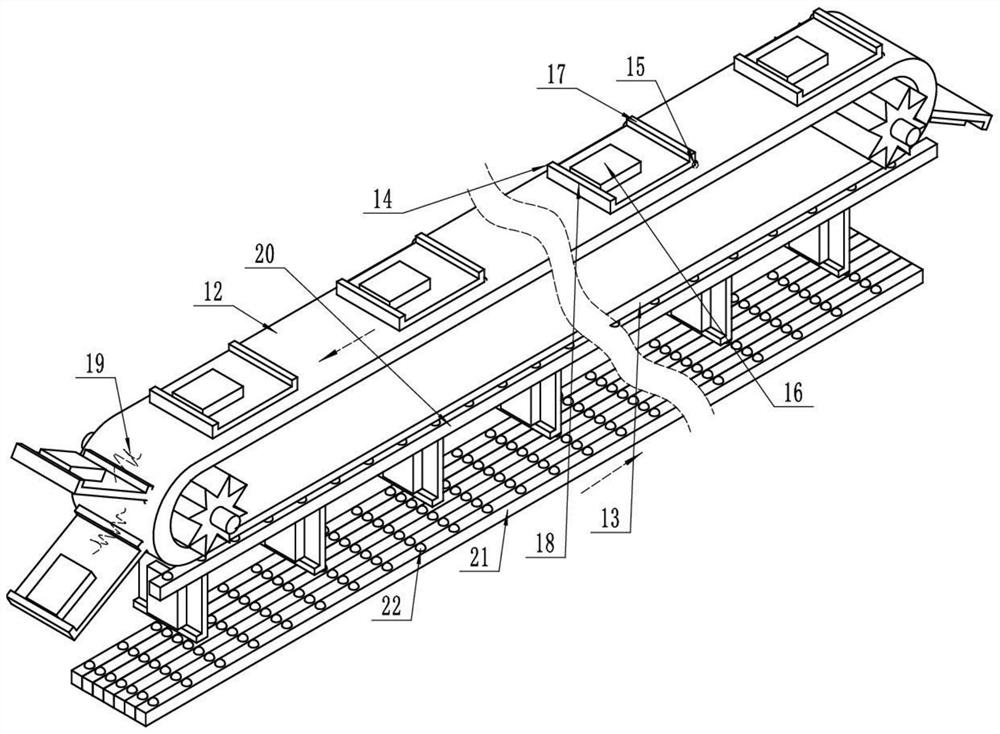

[0062] Such as Figure 1-6 As shown, the automatic loading and unloading robot for parts processing in this embodiment is used to transmit the workpiece 1 to be loaded and unloaded to realize the connection between each station; it includes the first outer pair of conveyor belts 2 and the adjacent first A second inner pair of conveyor belts 3 between the outer pair of conveyor belts 2;

[0063] The output end of the first first outer pair of conveyor belts 2 is located between the input end and the output end of the second inner pair of conveyor belts 3; the input end of the second first outer pair of conveyor belts 2 is located at the input end of the second inner pair of conveyor belts 3 between the output terminal;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com