Refrigerant replacing r-134a and its preparation method and application

The technology of a refrigerant, R-152, is applied in the field of the refrigerant that replaces R-134A and its preparation, which can solve the problems of high drying and cleaning requirements of the refrigeration system, no environmental protection features, unfavorable refrigeration system, etc., and achieves good energy saving effect. , The effect of large latent heat of evaporation and avoiding equipment waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

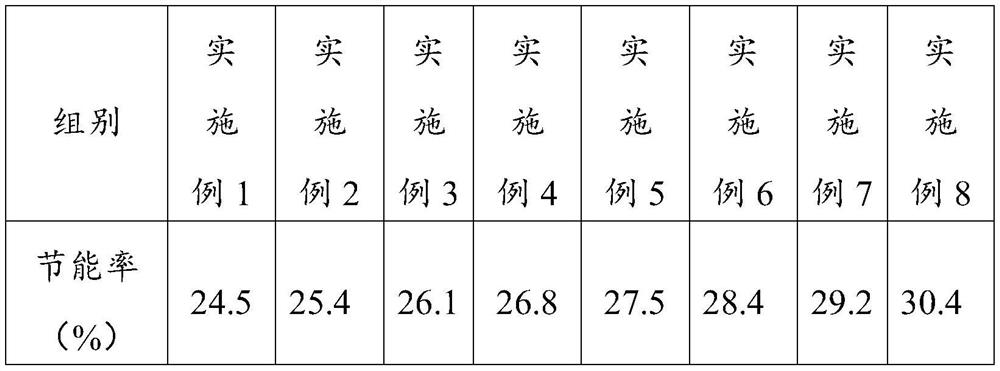

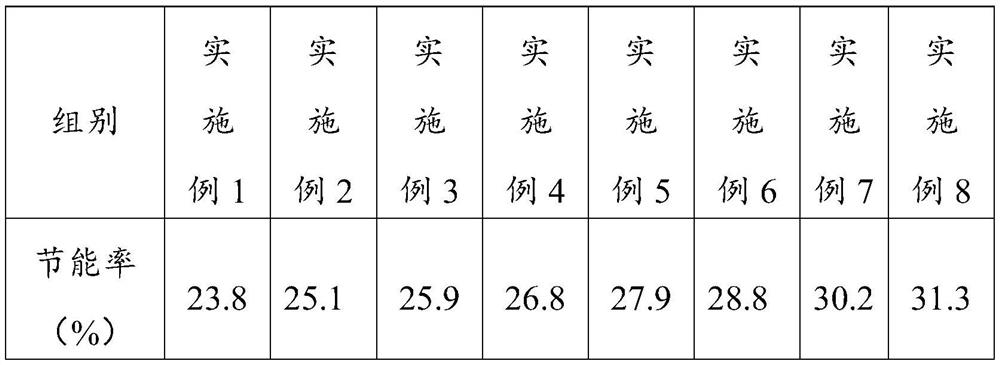

Examples

Embodiment 1

[0042] A refrigerant replacing R-134A, which is prepared by fully mixing the following raw materials in parts by weight: 22.5 parts of fluoroethane; 31.7 parts of propylene; 23.6 parts of difluoroethane; 22.2 parts of trifluoroiodomethane.

[0043] Its preparation method is as follows:

[0044] S1. Carry out rectification and purification of the three raw materials on the production line, and the height of the rectification tower must reach the height and standard for producing 99.96% of refrigerant raw materials;

[0045] S2. The purity of the three raw materials is tested by an Agilent color analyzer to ensure that the purity reaches 99.96% of refrigerant grade;

[0046] S3. Connect the fully automatic mixing tank, and connect the fully automatic and multi-functional microwave vacuum mixing tank. The model of the fully automatic and multi-functional microwave vacuum mixing tank is: YDL--6000L. The multifunctional microwave vacuum mixing tank has a fast heat reflux speed, ca...

Embodiment 2

[0054] A refrigerant replacing R-134A, which is prepared by fully mixing the following raw materials in parts by weight: 24.5 parts of fluoroethane; 29.6 parts of propylene; 22.8 parts of difluoroethane; 23.1 parts of trifluoroiodomethane and its preparation method Refer to the examples.

Embodiment 3

[0056] A refrigerant that replaces R-134A, which is made by fully mixing the following raw materials in parts by weight:

[0057] 25.8 parts of fluoroethane; 27.8 parts of propylene; 24.6 parts of difluoroethane; 21.8 parts of trifluoroiodomethane

[0058] Its preparation method refers to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com