Visual detection system and method for through hole of transparent plate

A technology of transparent plate and visual inspection, which is applied in the directions of measuring devices, analyzing materials, and optical testing for flaws/defects, etc. It can solve problems such as low product yield, low production efficiency, and inability to analyze online, so as to improve processing quality and real-time Good performance, improve production efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

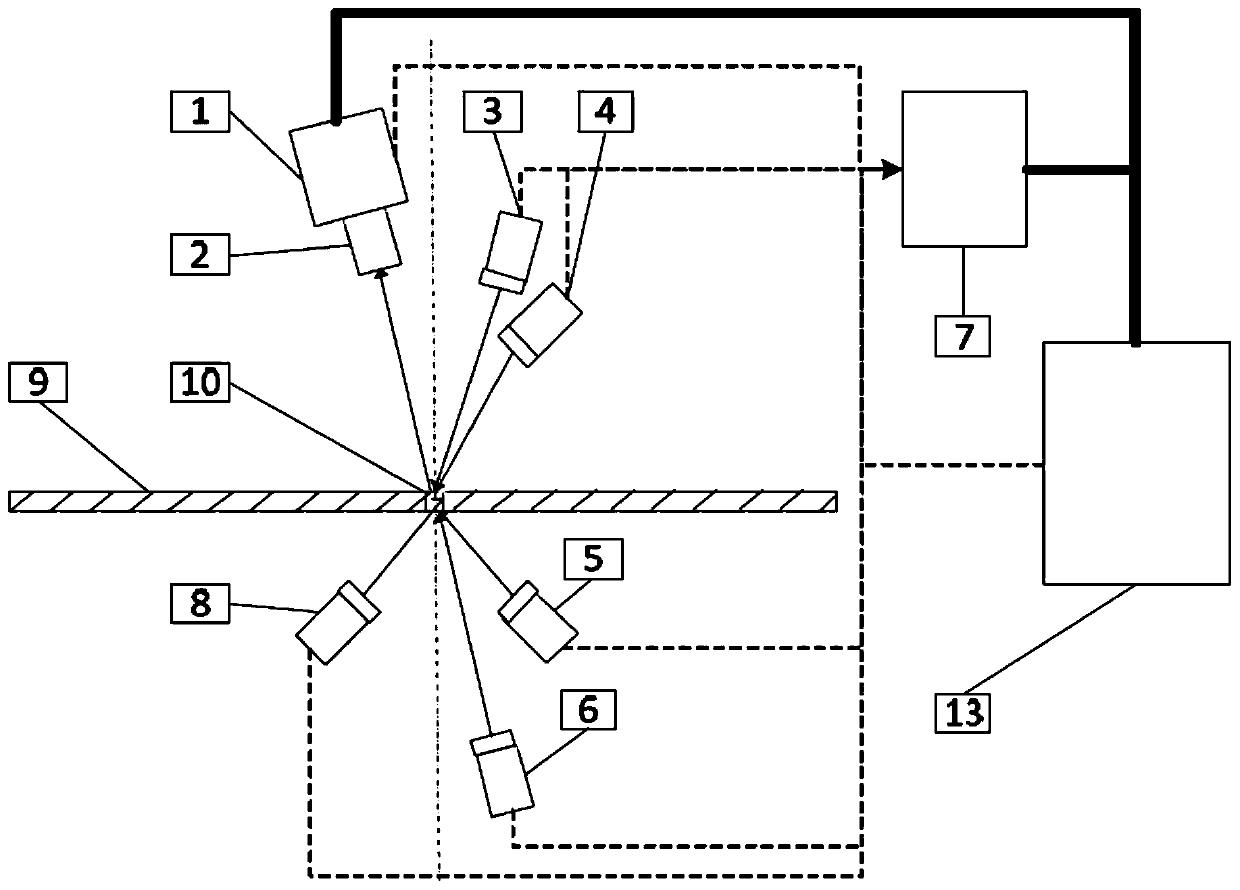

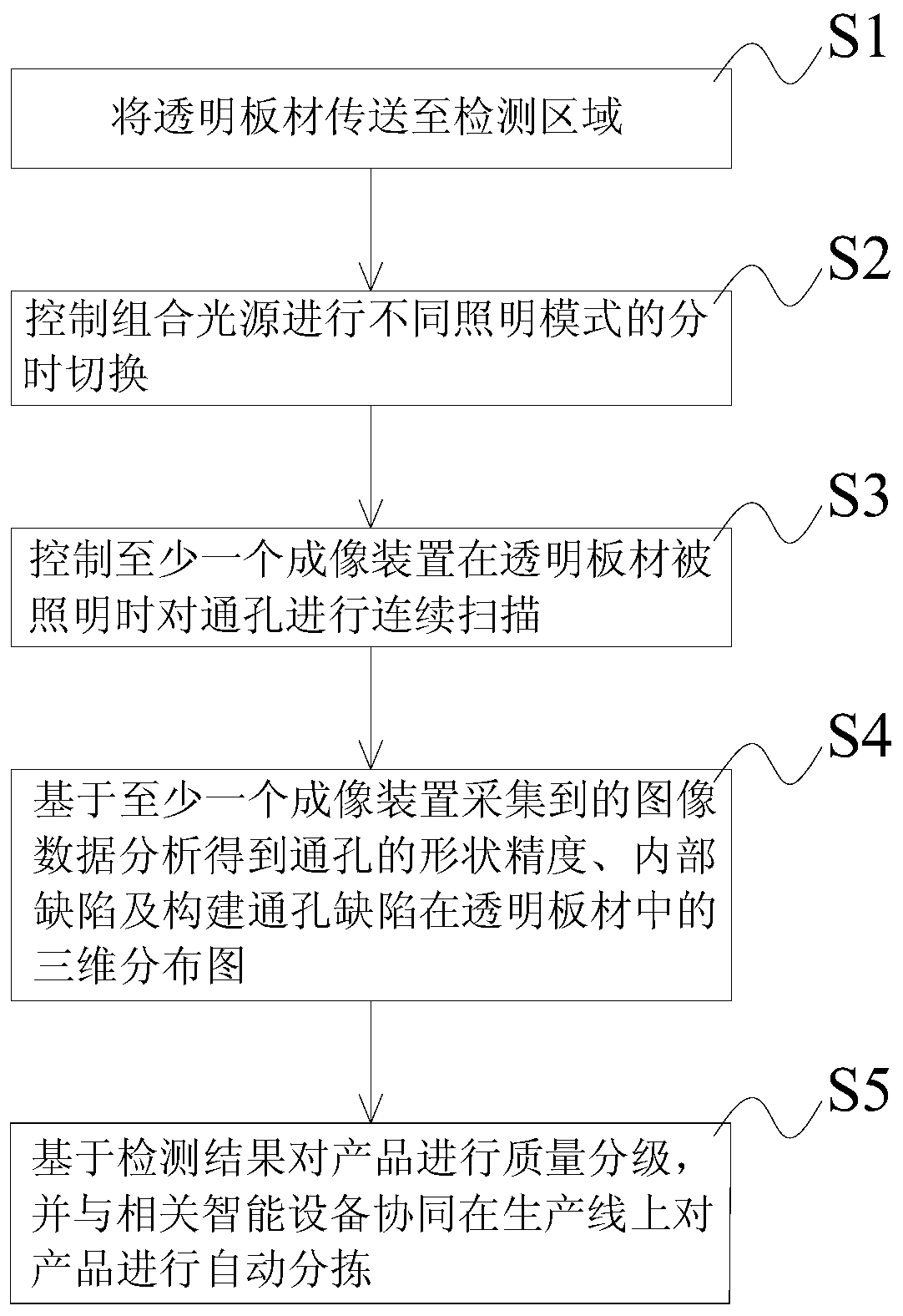

[0061] For ease of understanding, such as figure 1 As shown, the preferred embodiment of the present invention provides a visual inspection system for through-holes in transparent plates comprising:

[0062] At least one imaging device 1 is used for imaging and scanning the through hole 10 on the transparent plate 9;

[0063] Combined light sources for providing lighting;

[0064] A conveying device, used for relative movement between the transparent plate 9 and the imaging device 1;

[0065] A controller 7, configured to control the combined light source to perform time-sharing switching of illumination modes and control at least one imaging device 1 to perform image acquisition in different illumination modes;

[0066] The processor 13 is used to generate con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com