Digital monitoring and management system for concrete pouring

A monitoring management, concrete technology, applied in the transmission system, processing of building materials, construction, etc., can solve the problems that the data cannot be collected and stored in time, affect the project delivery time, and cannot manage the globalization of concrete pouring operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

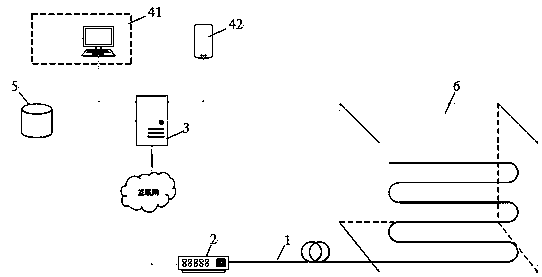

[0021] As shown in the figure, a concrete pouring digital monitoring and management system of the present invention includes a sensing optical fiber 1 , an optical fiber sensing detection unit 2 , a cloud server 3 , a client 4 and a database 5 .

[0022] The sensing optical fiber is arranged in the concrete pouring area 6, which can be a temperature sensing optical fiber or a vibration sensing optical fiber. According to the data that needs to be monitored during specific construction, the temperature sensing optical fiber and the vibration sensing optical fiber can also be monitored at the same time. to lay.

[0023] After laying, a 3D model is made on the pouring ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com