Method for eliminating electrostatic adsorption of surface acoustic wave filter

A surface acoustic wave, electrostatic adsorption technology, applied in the direction of static electricity, electrical components, etc., can solve the problem that the static electricity of the surface acoustic wave filter cannot be completely eliminated, and achieve the effect of solving electrostatic adsorption, lasting anti-static, and overcoming static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

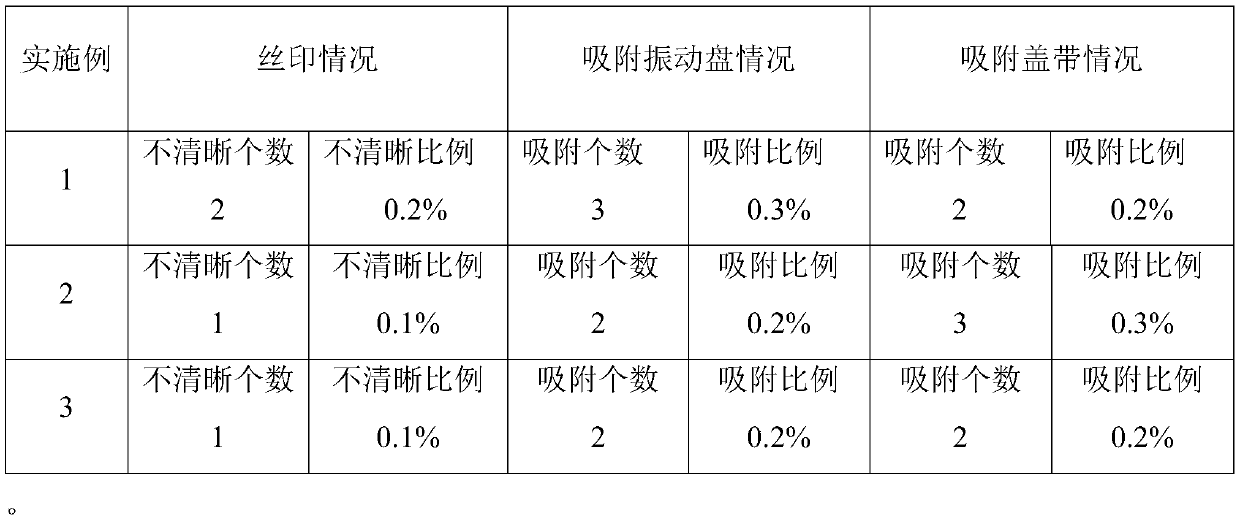

Embodiment 1

[0027] A. Take 9 liters of ethanol at room temperature and place it in a bucket with a volume of about 12 liters. Then, add 1 liter of electrostatic agent containing 50% polyacetylene, 30% polyaniline, and 20% polypyrrole to the bucket. Stir while adding; after the electrostatic agent is added, the mixed solution is fully stirred for 1 minute to completely dissolve the electrostatic agent in ethanol.

[0028] B. Take a 10-mesh filter screen and completely wrap about 10,000 surface acoustic wave filters to be processed. Under the premise of not leaking the surface acoustic wave filter, make the surface acoustic wave filter in the filter screen as large as possible. Disperse; Then, place the filter screen wrapped with the surface acoustic wave filter in the destaticizing solvent obtained in step A, so that the surface acoustic wave filter in the filter screen is completely immersed in the destaticizing solvent, soak For 1 minute, the polymer conductive material in the static rem...

Embodiment 2

[0038] A. Take 9.5 liters of ethanol at room temperature and place it in a bucket with a volume of about 12 liters. Then, add 0.5 liters of electrostatic agent containing 40% polyaniline, 30% polypyrrole, and 30% polythiophene to the bucket. Stir while adding; after the addition of the electrostatic agent is completed, the mixed solution is fully stirred for 2 minutes to completely dissolve the electrostatic agent in ethanol.

[0039] B. Take an 8-mesh filter screen, completely wrap the surface acoustic wave filter to be processed at about 20K, and make the surface acoustic wave filter in the filter screen as scattered as possible under the premise of not leaking the surface acoustic wave filter; Then, place the filter screen wrapped with the surface acoustic wave filter in the antistatic solvent prepared in step A, so that the surface acoustic wave filter in the filter screen is completely immersed in the antistatic solvent, and soak for 1 minute , so that the polymer conduct...

Embodiment 3

[0049] A. Take 9.9 liters of ethanol at room temperature and place it in a bucket with a volume of about 12 liters. Then, add 0.1 liter of electrostatic agent containing 30% polyacetylene, 40% polyaniline, and 30% polythiophene to the bucket. Stir while adding; after the addition of the electrostatic agent is completed, the mixed solution is fully stirred for 2 minutes to completely dissolve the electrostatic agent in ethanol.

[0050] B. Take a 12-mesh filter screen, completely wrap the surface acoustic wave filter to be processed at about 20K, and make the surface acoustic wave filter in the filter screen as scattered as possible under the premise of not leaking the surface acoustic wave filter; Then, place the filter screen wrapped with the surface acoustic wave filter in the antistatic solvent prepared by step A, so that the surface acoustic wave filter in the filter screen is completely immersed in the antistatic solvent, and soak for 2 minutes , so that the polymer condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com