Goaf circulating grouting and filling system for treating solid waste

A technology for solid waste and gobs, which is applied in the field of solid waste treatment systems, can solve the problems of high cost, restrictions on the promotion and application of filling technology, and large investment, and achieve the effect of low cost, small impact, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

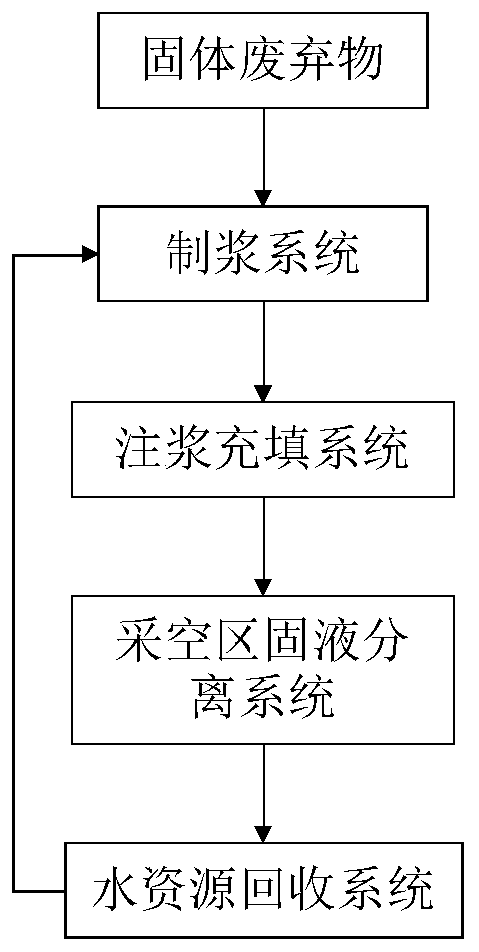

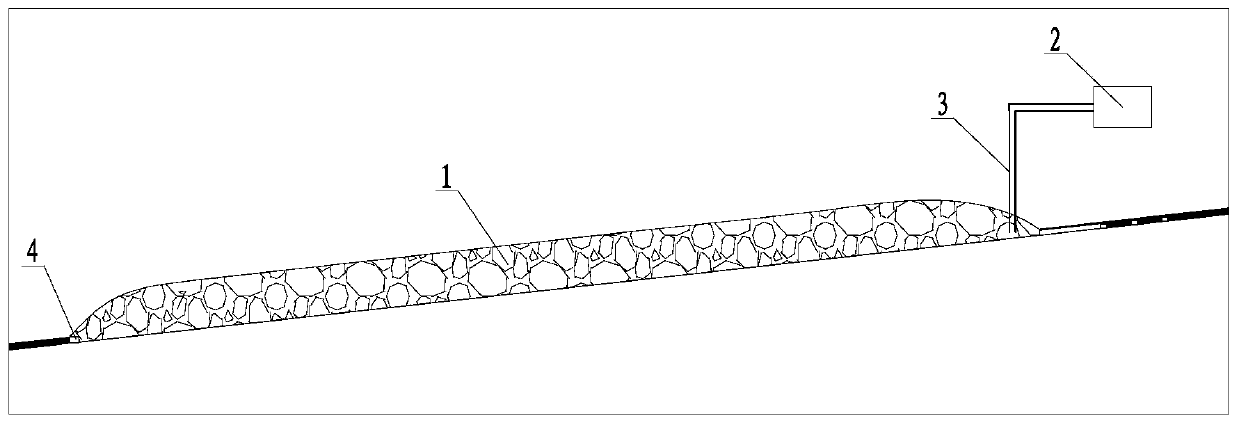

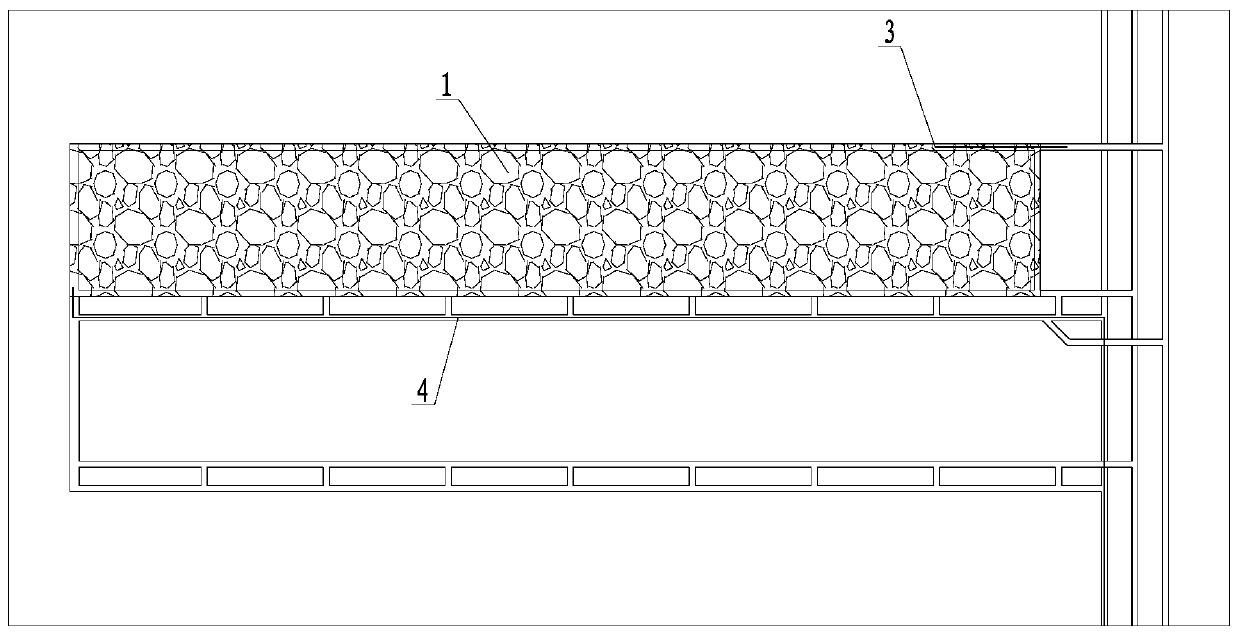

[0021] Such as Figure 1 to Figure 3 As shown, the gob circulating grouting filling system for treating solid waste provided by the present invention includes a slurrying system 2 , a grouting filling system 3 and a water resource recovery system 4 .

[0022] Among them, the pulping system 2 is used to grind the solid waste to be treated into tiny particles with a set particle size, and mix it with water to make a slurry with a specific concentration; the grouting filling system 3 is used to make the pulping system 2 The formed slurry is injected into the goaf 1 from the high level, and the filtration characteristics of the goaf and the sedimentation characteristics of the slurry are used to make the solid-liquid separation occur in the process of the slurry flowing from the high level to the low level in the goaf 1, and the solid particles are deposited in the gob. G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com