Eight-type multi-station die

A multi-station, mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of manual picking and placing parts safety hazards, multiple labor and equipment costs, high product scrap rate, etc., to save labor and equipment. The effect of cost, easy and reliable disassembly and assembly of inserts, and high product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

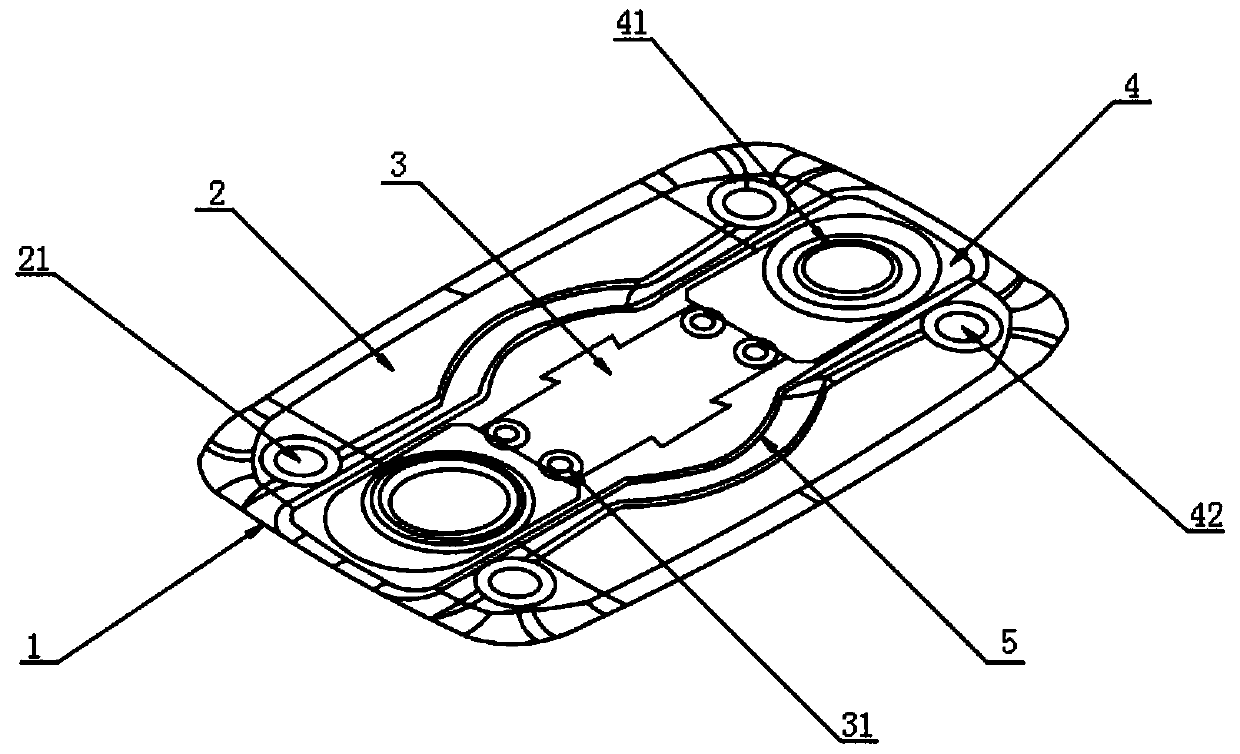

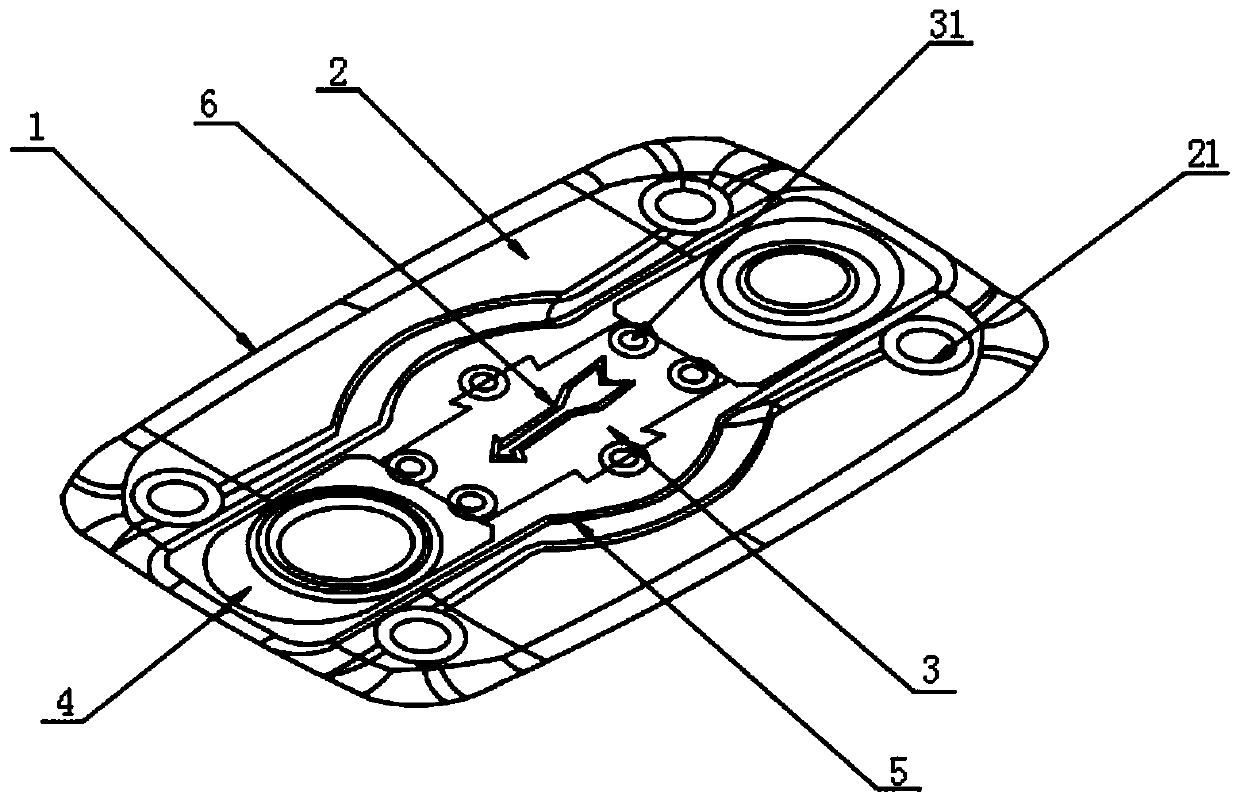

[0025] The present invention provides such Figure 1-5 A kind of eight-type multi-station mold shown comprises a base 1, and the top of the base 1 is fixed with a main mold 2, and the top of the main mold 2 is provided with a middle punch 3, and both sides of the middle punch 3 are An outer concave-convex mold 4 is provided, and the outer concave-convex mold 4 is fixedly arranged at both ends of the top of the main mold 2. A trapezoidal groove 5 is provided between the main mold 2 and the base 1, and a middle concave-convex mold is provided on the top of the middle convex mold 3. Die mosaic seat 6, concave-convex mold mosaic seat 7 is provided on the top of the outer concave-convex mold 4, positioning seat 8 is provided on the front side and rear side surface of the base 1, and connecting seat 9 is provided on the surface of both sides of the base 1 .

[0026] Further, the surface of the main mold 2 is evenly provided with a main mold positioning hole 21, and the outside of t...

Embodiment 2

[0030] Further, the top of the outer concave-convex mold 4 is provided with an inlay hole 41, and the outer side of the outer concave-convex mold 4 is provided with a concave-convex mold positioning hole 42, and the concave-convex mold positioning hole 42 is arranged between the outer concave-convex mold 4 and the base 1 and Set for tilt.

[0031] Further, the trapezoidal groove 5 is hollow, the trapezoidal groove 5 is obliquely provided with stoppers on both sides, the outside of the trapezoidal groove 5 is provided with an opening, and the opening is provided at one end of the base 1 .

[0032] Beneficial effects of this embodiment: before use, the mold is fixed by connecting different types of positioning bolts through the positioning holes, and the waste generated during the production process will slowly fall in the main mold 2 and slide down to the inside of the inclined trapezoidal groove 5, After the production is completed, the waste chips can be quickly cleaned by cl...

Embodiment 3

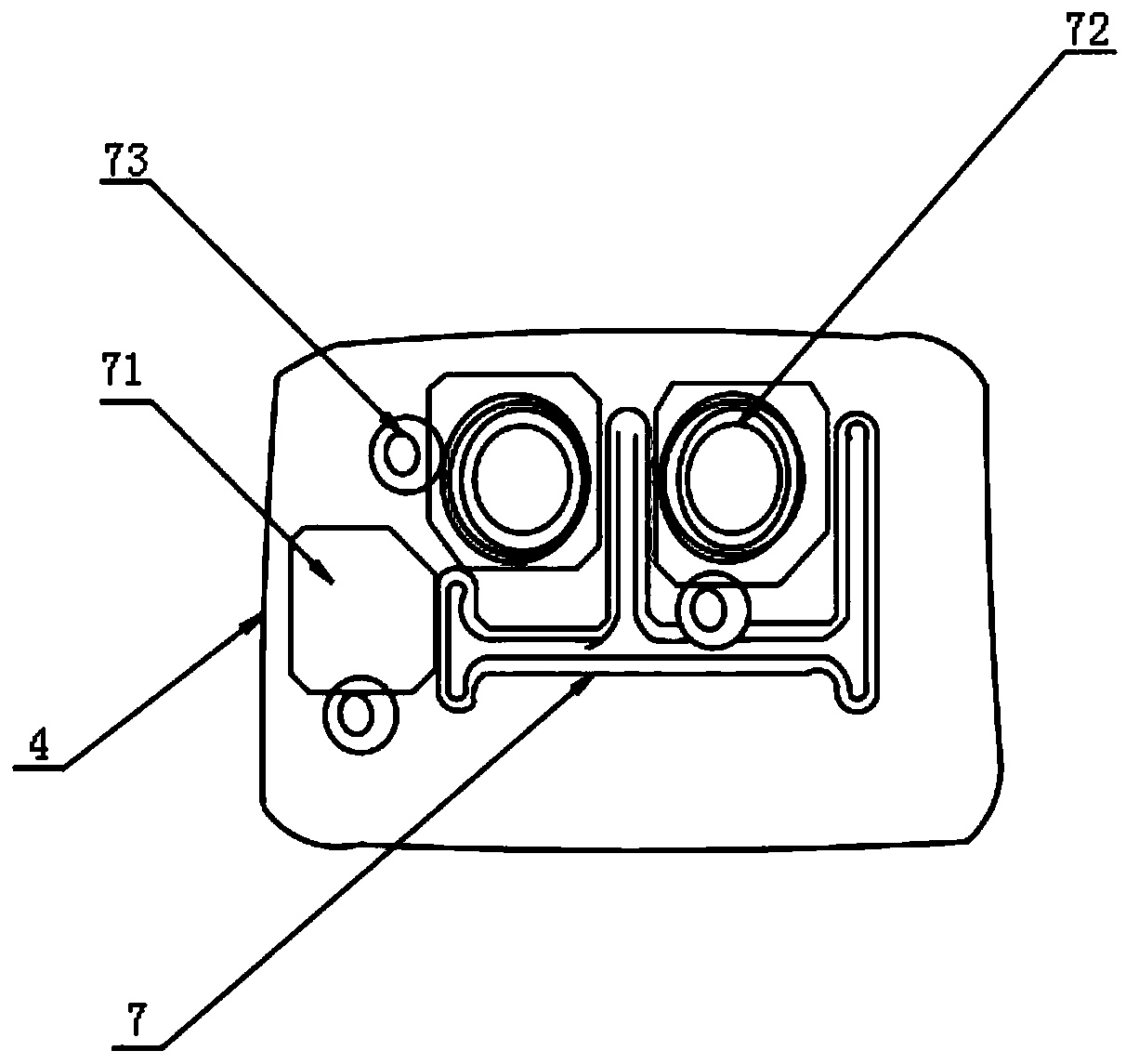

[0034] Further, the outside of the concave-convex mold inlay seat 7 is provided with a mosaic seat positioning plate 71, and the top of the concave-convex mold inlay seat 7 is provided with alignment holes 72, and the alignment holes 72 are matched with the inlay holes 41. A fastening hole 73 is provided outside the positioning hole 72 .

[0035] Further, a positioning plate is connected to the outside of the positioning seat 8, the positioning seat 8 is used to limit the position of the base 1, and a connection hole is provided on the top of the connecting seat 9, and the connecting seat 9 is used to connect processing tools .

[0036] Beneficial effects of this embodiment: the positioning seat 8 is used to limit the position of the base 1, the connecting seat 9 is used to connect the processing equipment, and the automatic integration of three-dimensional manipulator feeding is adopted, which avoids the safety hazard of manual pick-up and production. High efficiency, saving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com