Automatic cutting device for square plate section at end of pipe pile.

A technology of automatic cutting device and pipe pile, which is applied to shearing devices, accessories of shearing machines, maintenance and safety accessories, etc. , increase the accuracy, provide the effect of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

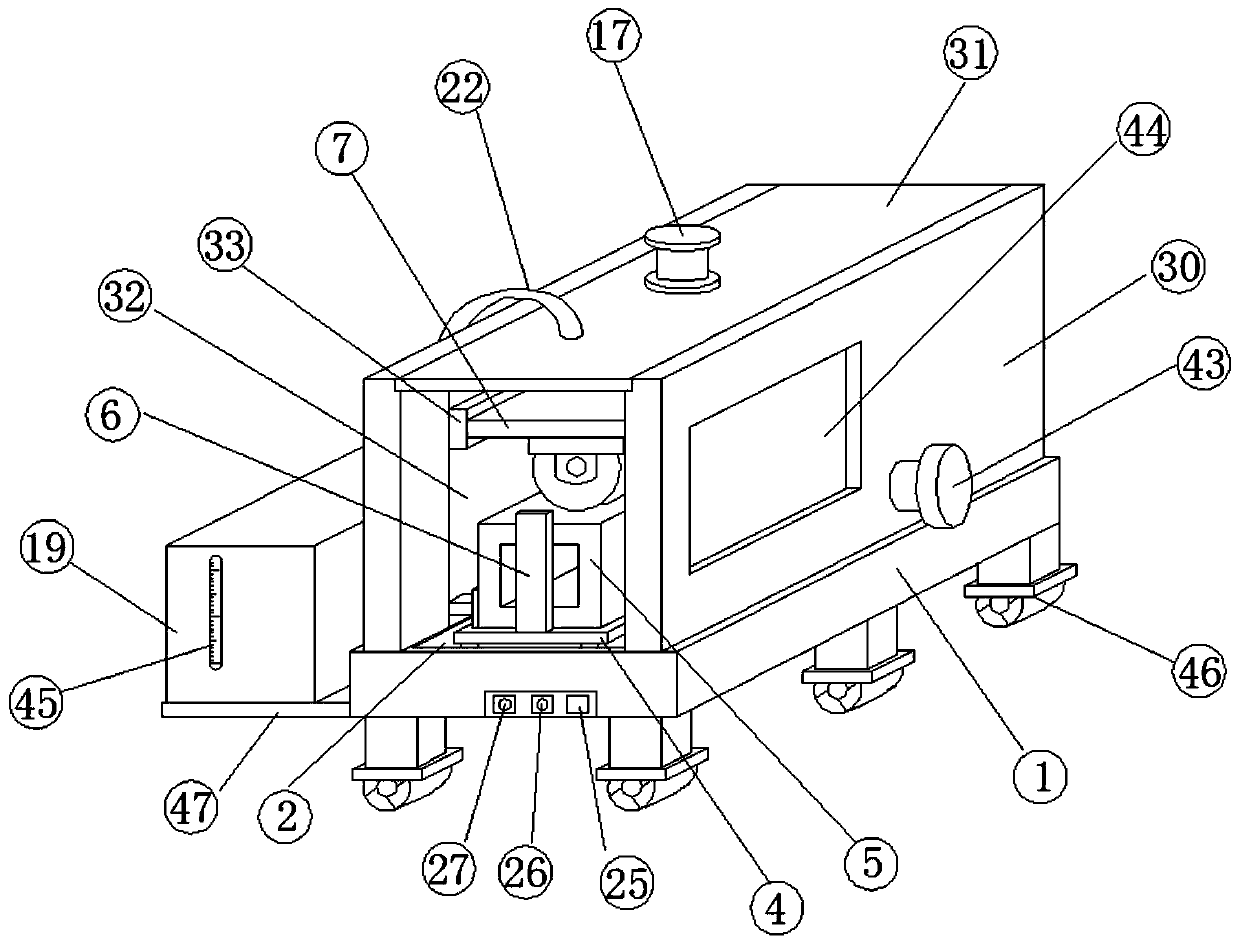

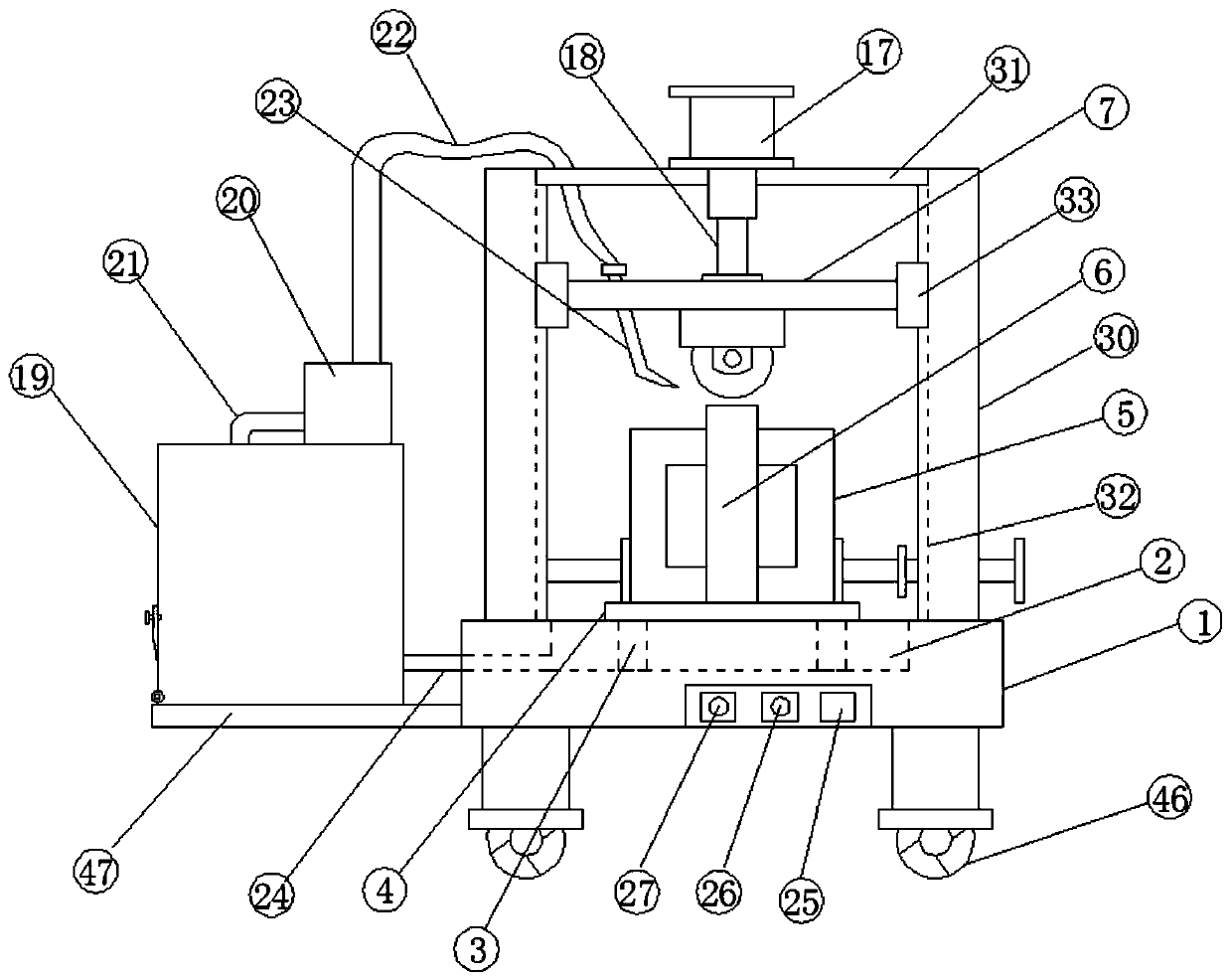

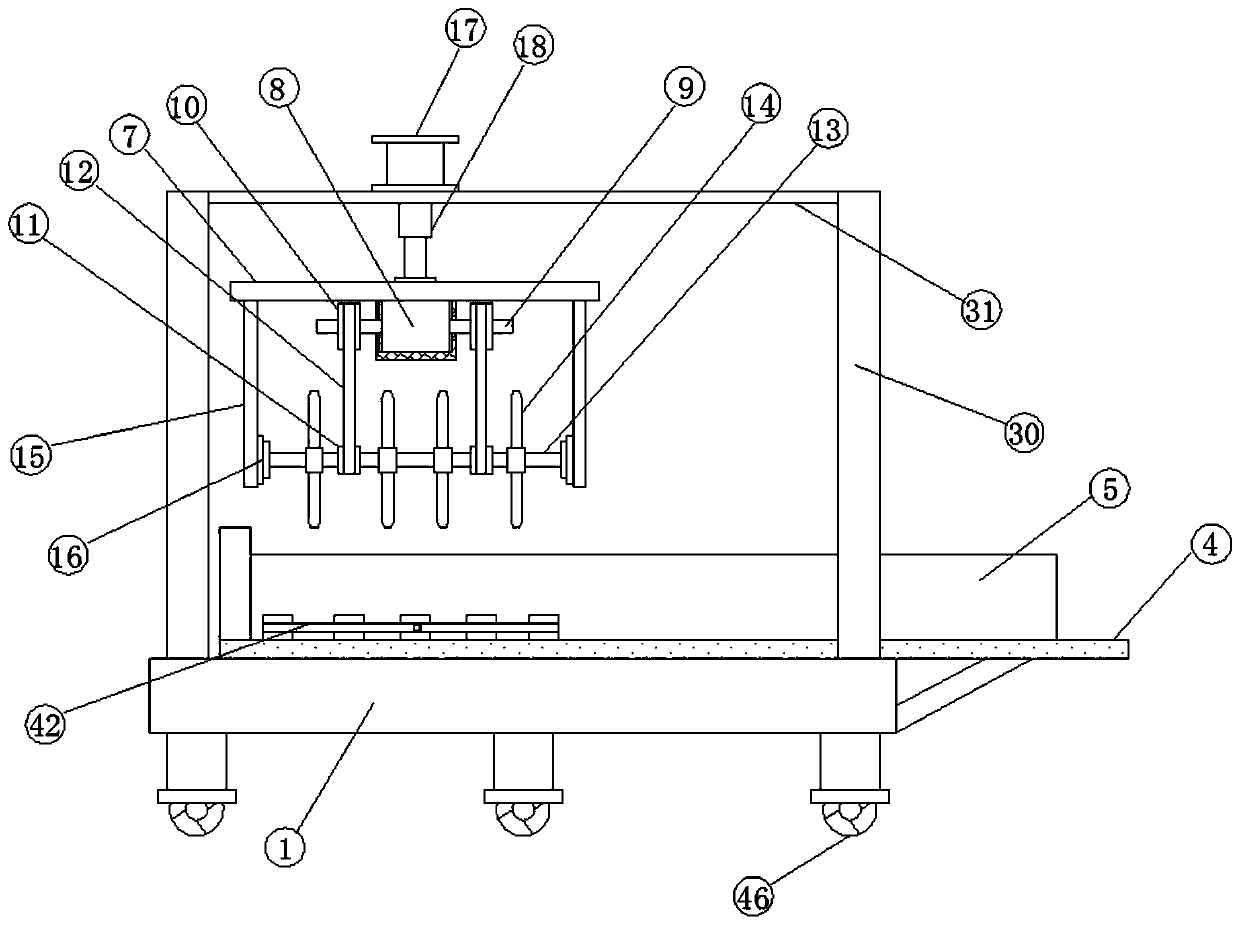

[0032] see Figure 1-5 , according to an embodiment of the present invention, an automatic cutting device for square plate segments at the end of pipe piles includes an operating table 1, a water receiving tank 2 is provided in the middle of the operating table 1, and a support is fixed inside the water receiving tank 2 Column 3, the end of the support column 3 away from the water tank 2 is fixed with a placement table 4, the placement table 4 is provided with a square plate 5, and the two sides of the square plate 5 are provided with clamping devices, so One end of the placement table 4 is fixedly provided with a limit baffle 6, a cutting device is provided above the square plate 5, and the cutting device includes a lifting plate 7, and a side of the lifting plate 7 is provided with a biaxial motor 8, The output end of described biaxial motor 8 is provided with rotating shaft 9, and first gear 10 is fixedly arranged on described rotating shaft 9, and the below of described fi...

Embodiment 2

[0034] see figure 1 , 2 , 3, 5, for the clamping device, the clamping device includes several clamping blocks 41, one end of the clamping block 41 is fixedly provided with a connecting rod, and the end of the connecting rod far away from the clamping block 41 is connected with The push plate 42 is fixedly connected, the end of the push plate 42 away from the connecting rod is provided with a threaded rod 43, the threaded rod 43 runs through the support device, and the threaded rod 43 is threadedly connected with the support device, One end of the threaded rod 43 is connected to the push plate 42 through the second bearing seat, and the side of the square plate 5 away from the clamping block 41 is provided with an auxiliary device, and the clamping device can be placed on the placement table 4 The square plate plays the role of clamping, so as to realize the effect of stability when cutting the square plate 5, avoid shaking in the cutting process, greatly increase the accuracy...

Embodiment 3

[0036] see figure 1 , 2 , 5, for the auxiliary device, the auxiliary device includes a fixed rod 28, one side of the fixed rod 28 is fixed with a stopper 29, and the end of the stopper 29 away from the fixed rod 28 is in contact with the side The plate 5 contacts, and the end of the fixed rod 28 away from the stopper 29 is fixedly connected with the support device. The auxiliary device can play the role of limit resistance when the clamping device clamps the opposite plate, increasing the clamping force. stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com