Automatic assembling method for snap springs and device

An automatic assembly and circlip technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as manual replacement of circlips, gearbox performance failure, uncontrollability, etc., to reduce manual operation workload, labor The effect of reducing the bit beat and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings. Those skilled in the art should understand that the following does not constitute a limitation to the protection scope of the present invention.

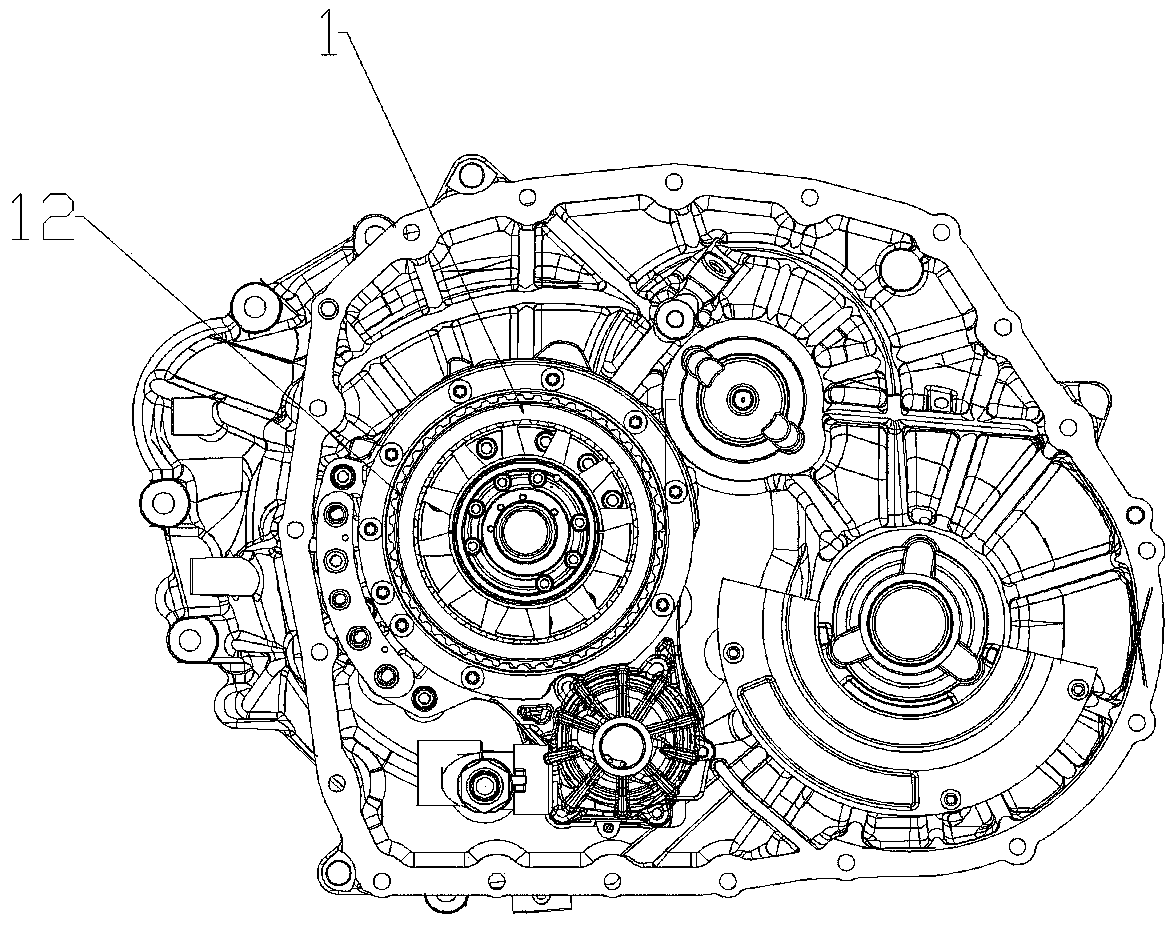

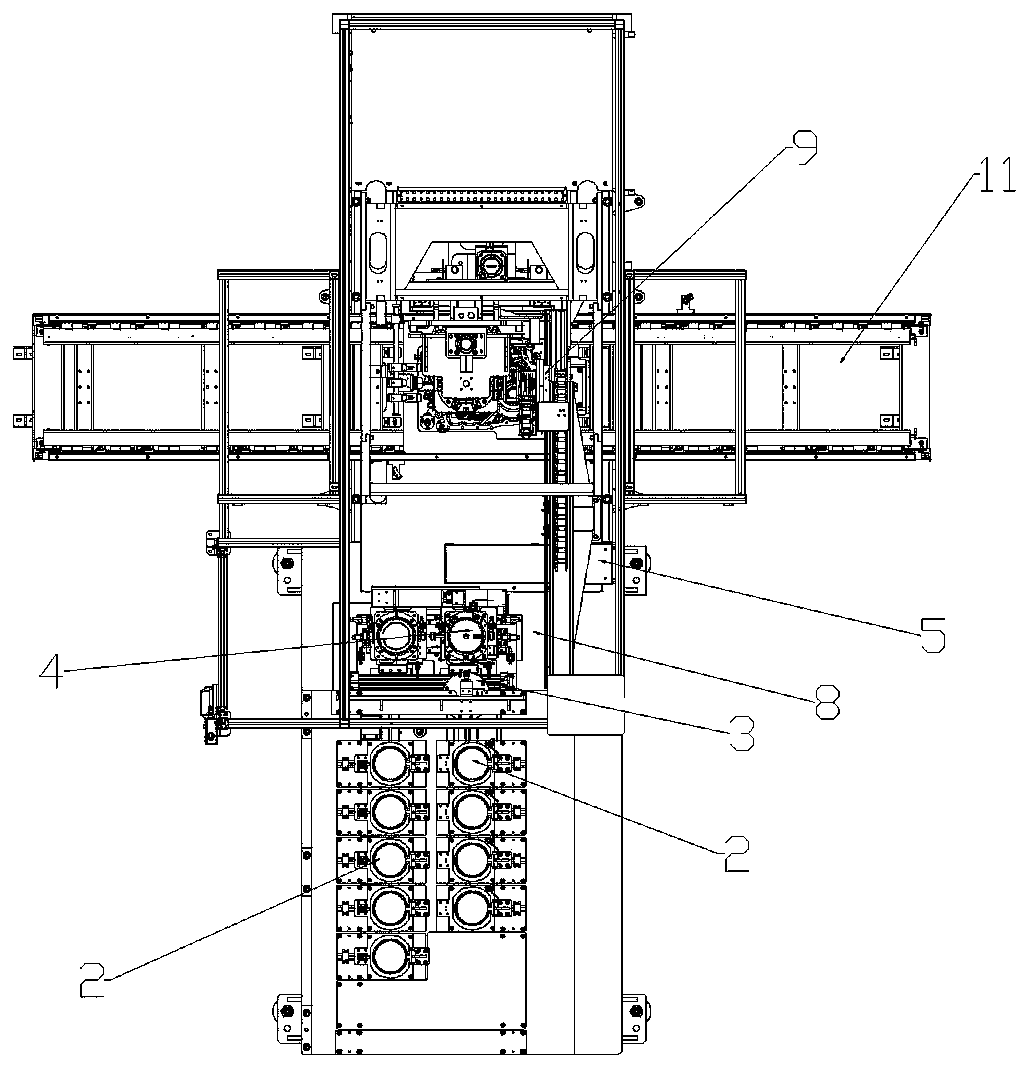

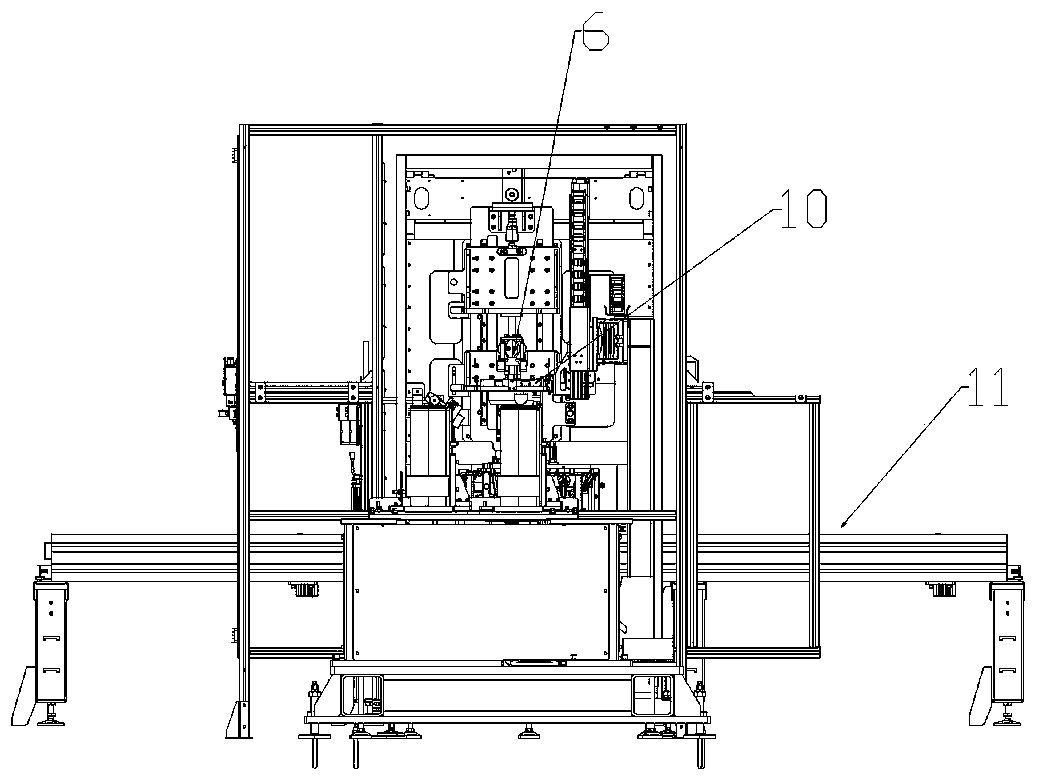

[0026] Examples such as figure 2 , image 3 , Figure 4 As shown, a device for implementing an automatic circlip assembly method includes an adjusting circlip 1 arranged on a bracket 11, a circlip magazine 2, a circlip thickness detection device 3, a circlip receiving device 4, and a circlip picking device. Material device 5, circlip pressure head 6, camera error prevention device 7, circlip retrieving device 9, circlip positioning and ring collection guide device 10 and bracket 11, the adjustment circlip series is generally 10, and the equipment is equipped with 10 clamps Spring feed bin 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com