Double-width decoiling automatic warehousing efficient intelligent combined cutting equipment

A shearing equipment, flat automatic technology, applied in the direction of shearing machine equipment, shearing device, metal processing equipment, etc., can solve the problems of no production line and low cutting technology efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

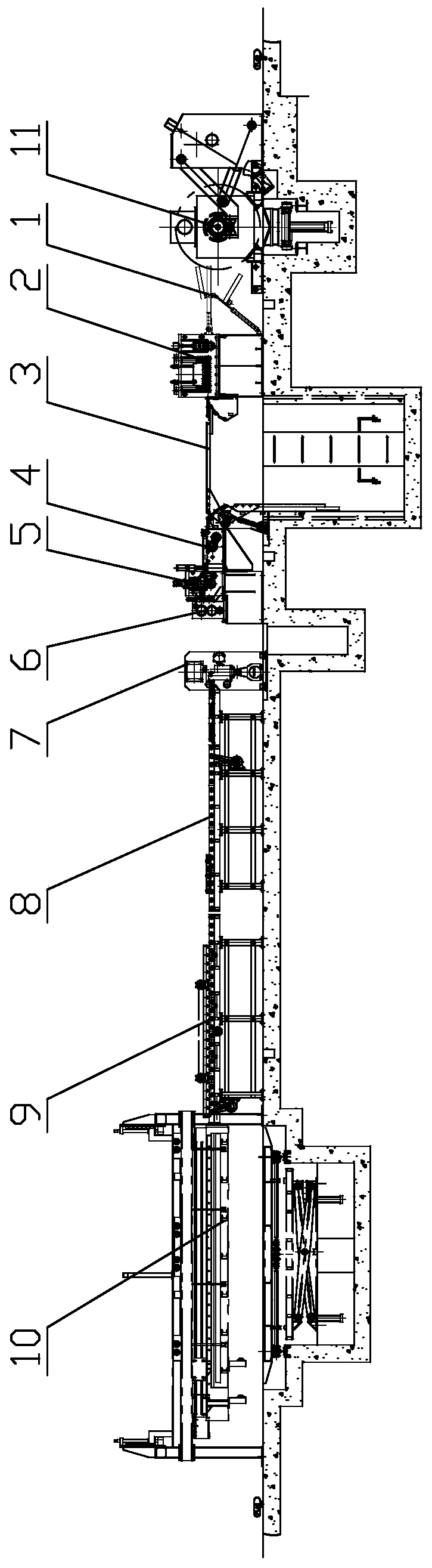

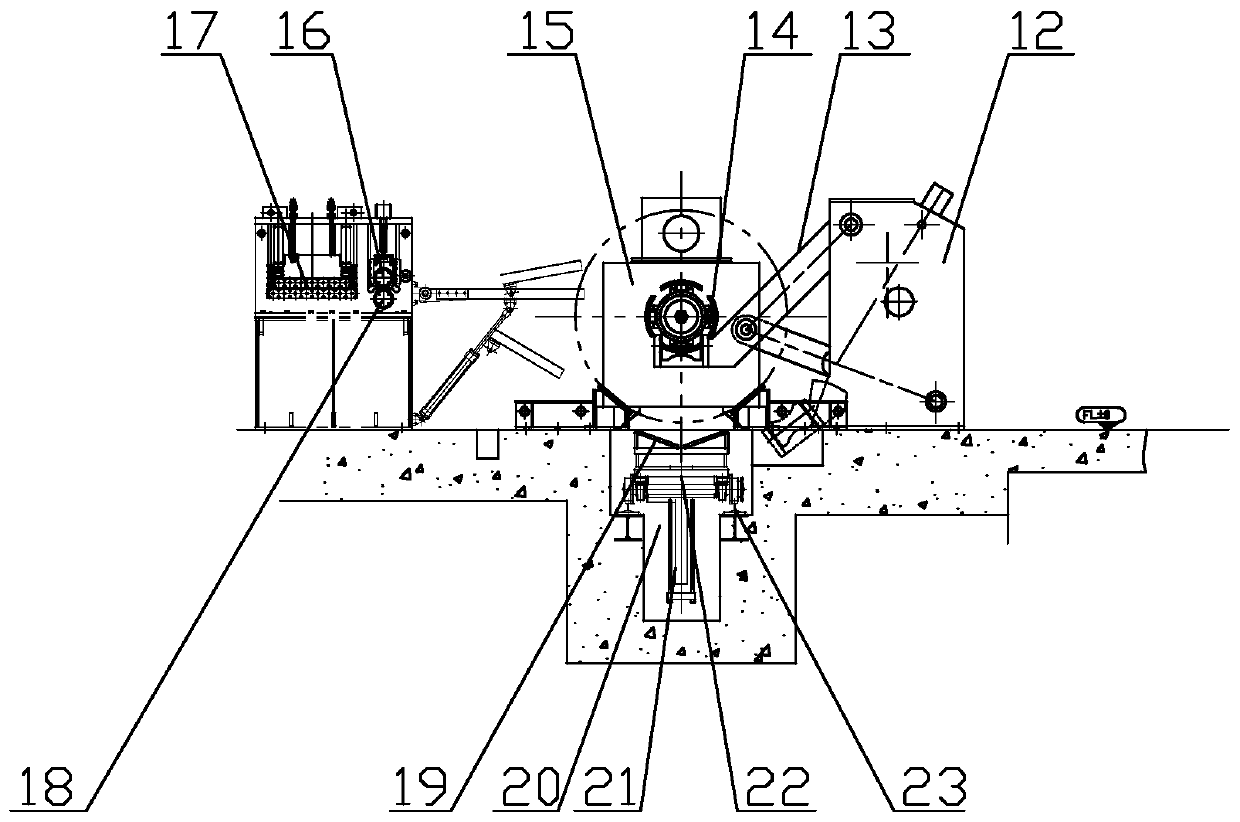

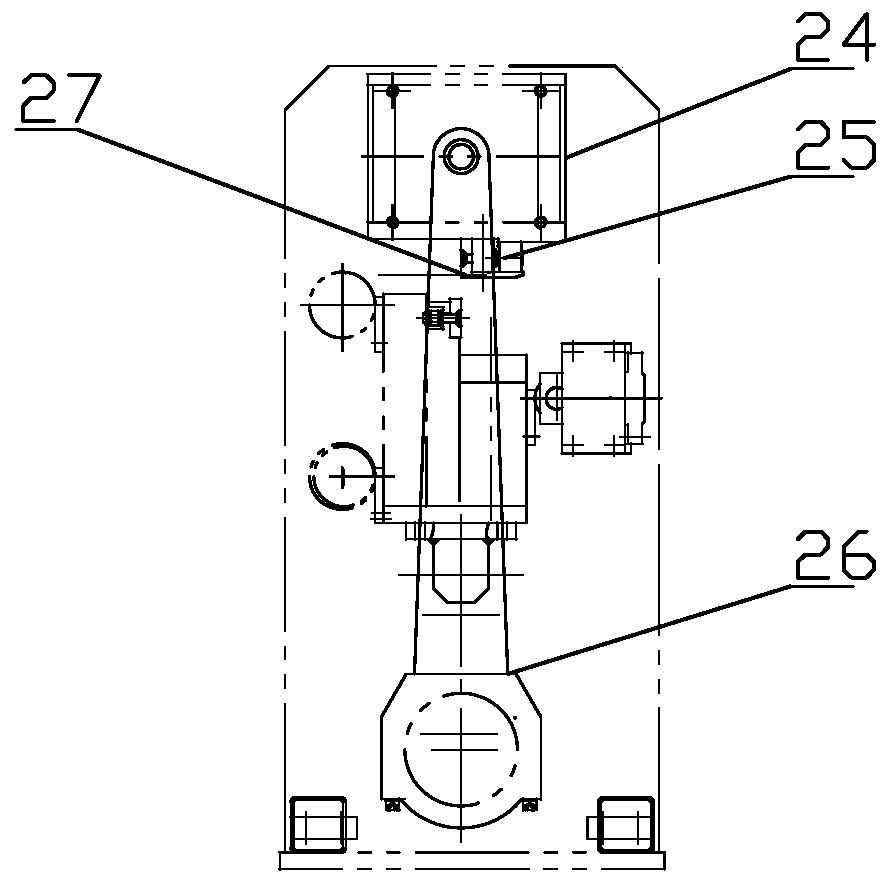

[0023] like Figure 1-4 As shown in the figure, the double-width opening and leveling automatic closing high-efficiency intelligent combined shearing equipment according to the present invention is provided with an uncoiler 11, and the uncoiler 11 is connected to the lead-in leveling machine 2, and the uncoiler 11 unfolds the material and passes through the lead-in leveling machine 2. The feeding device 1 installed on the top is fed into the lead-in leveling machine 2, and the lead-in leveling machine 2 is connected to the looper swing bridge 3, and the looper swing bridge 3 is connected to the rectifying device 4, the servo feeding device 5 and the slitting machine 6 in turn. The shearing machine 7 is connected to the blanking and stacking device 10 through the feeding roller table 8 and the material dividing roller table 9 in turn.

[0024] The double-width opening and leveling automatic closing high-efficiency intelligent combined shearing equipment, the uncoiler 11 has a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com