Plate cutting and positioning device

A positioning device and plate technology, which is applied to positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low work efficiency of plate positioning methods, and achieve the effects of simple operation, improved work efficiency, and enhanced positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

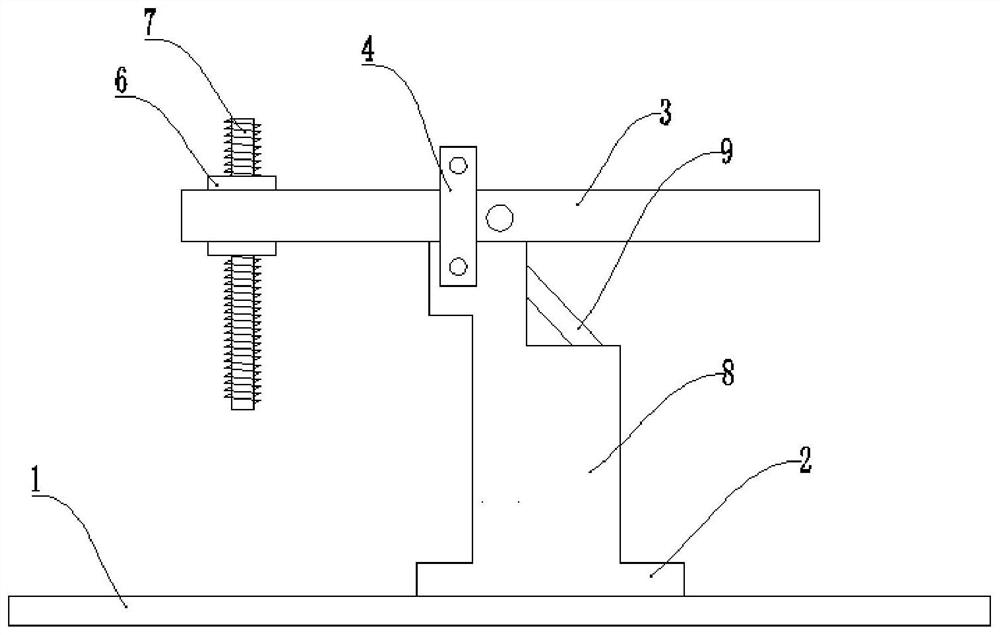

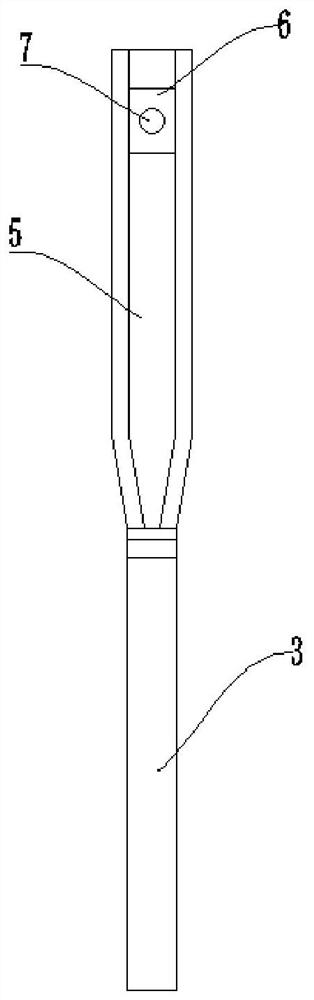

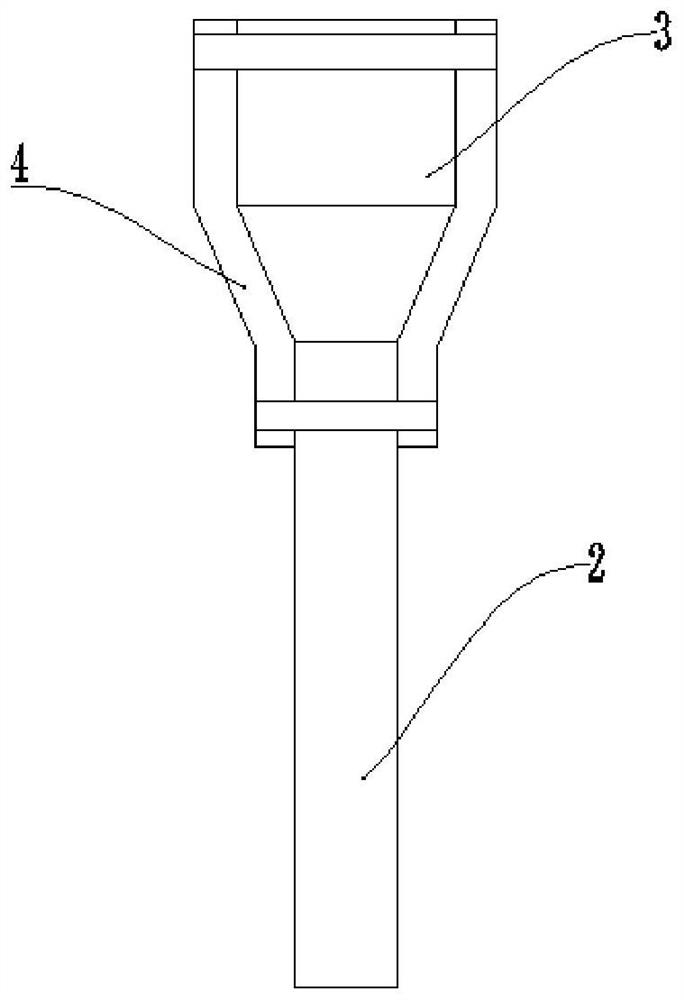

[0037] Basic as attached figure 1 , attached figure 2 And attached image 3 As shown: the plate cutting positioning device, including machine base 1, three positioning mechanisms for pressing both ends of the plate are equidistantly arranged on machine base 1 along the horizontal direction, the positioning mechanism includes support arm 2 and swing arm 3, support arm 2 and machine The seat 1 is fixedly connected, the middle part of the swing arm 3 is hinged with the top of the support arm 2, and the swing arm 3 and the support arm 2 are perpendicular to each other.

[0038] The support arm 2 is provided with a limit mechanism for limiting the position of the swing arm 3. The limit mechanism includes iron sheets 4 fixed on both sides of the support arm 2. The upper ends of the two iron sheets 4 are also affixed. The distance between 4 gradually decreases from top to bottom, and the swing arm 3 swings in the gap between the two iron pieces 4; the width of the left end of the ...

Embodiment 2

[0045] Basic as attached Figure 4 And attached Figure 5 As shown: the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that both sides of the slider 6 are provided with a stop mechanism for stopping the slider 6, and the stop mechanism includes the same The piston cylinder 10 fixed to the slider 6 and the piston plate 11 slidingly connected with the piston cylinder 10; the piston cylinder 10 is connected with an air outlet pipe 12; both sides of the chute 5 are provided with guide holes 13 along the length direction of the chute 5 The air outlet pipe 12 is slidingly connected with the guide hole 13, and the lower end of the air outlet pipe 12 away from the end of the piston cylinder 10 is connected with an air bag 14 for tightening the slider 6; First one-way valve 15; On the side wall of piston cylinder 10, be connected with inlet pipe 16, and the second one-way valve 17 that one-way flow to piston cylinder 10 direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com