High-voltage transmission line rescue robot and using method

A technology of high-voltage transmission lines and rescue robots, which is applied in the direction of overhead lines/cable equipment, manipulators, manufacturing tools, etc., can solve the problems of high energy consumption, small load capacity of robots, and many driving joints, so as to prevent shaking and save rescue time , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

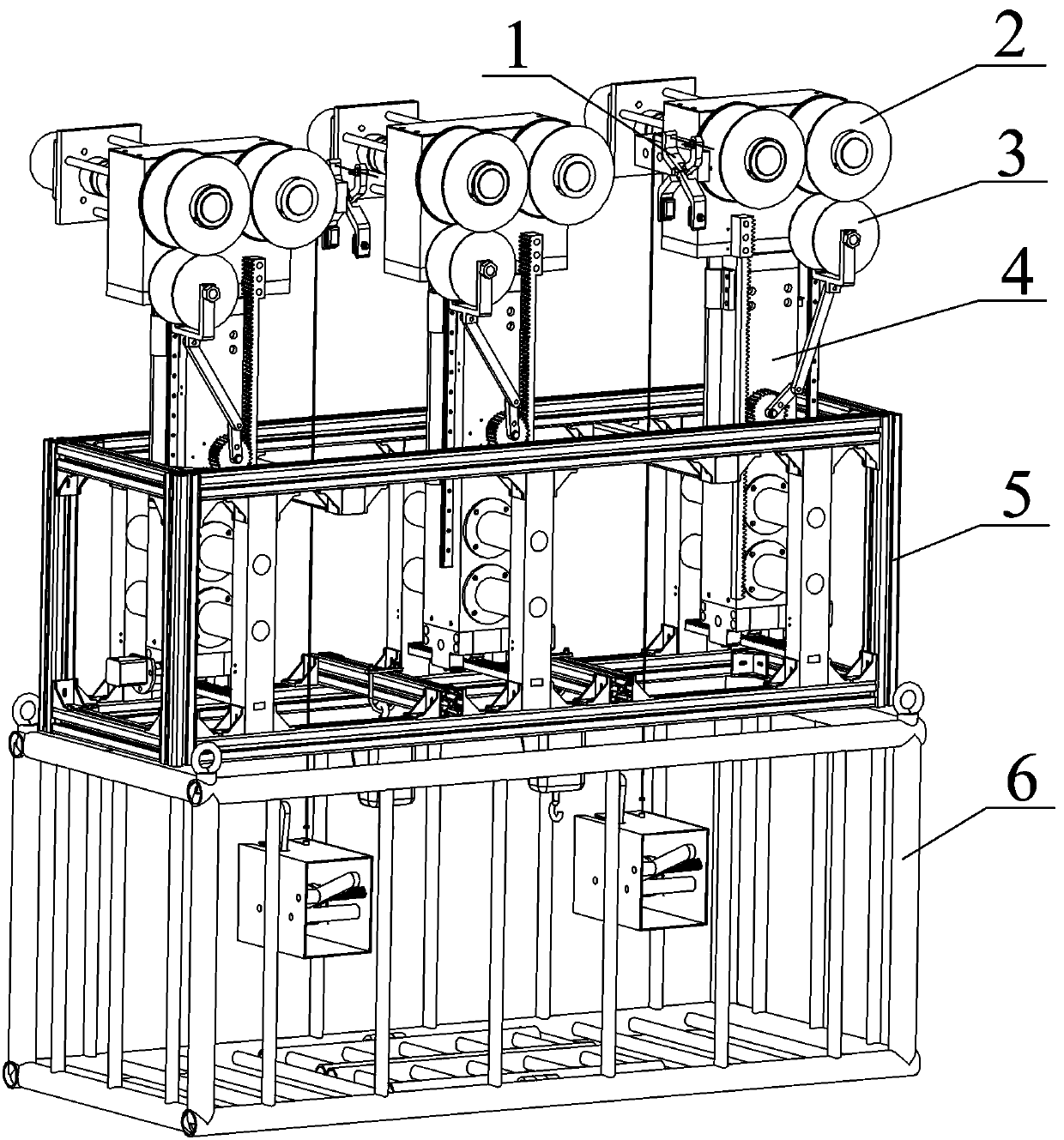

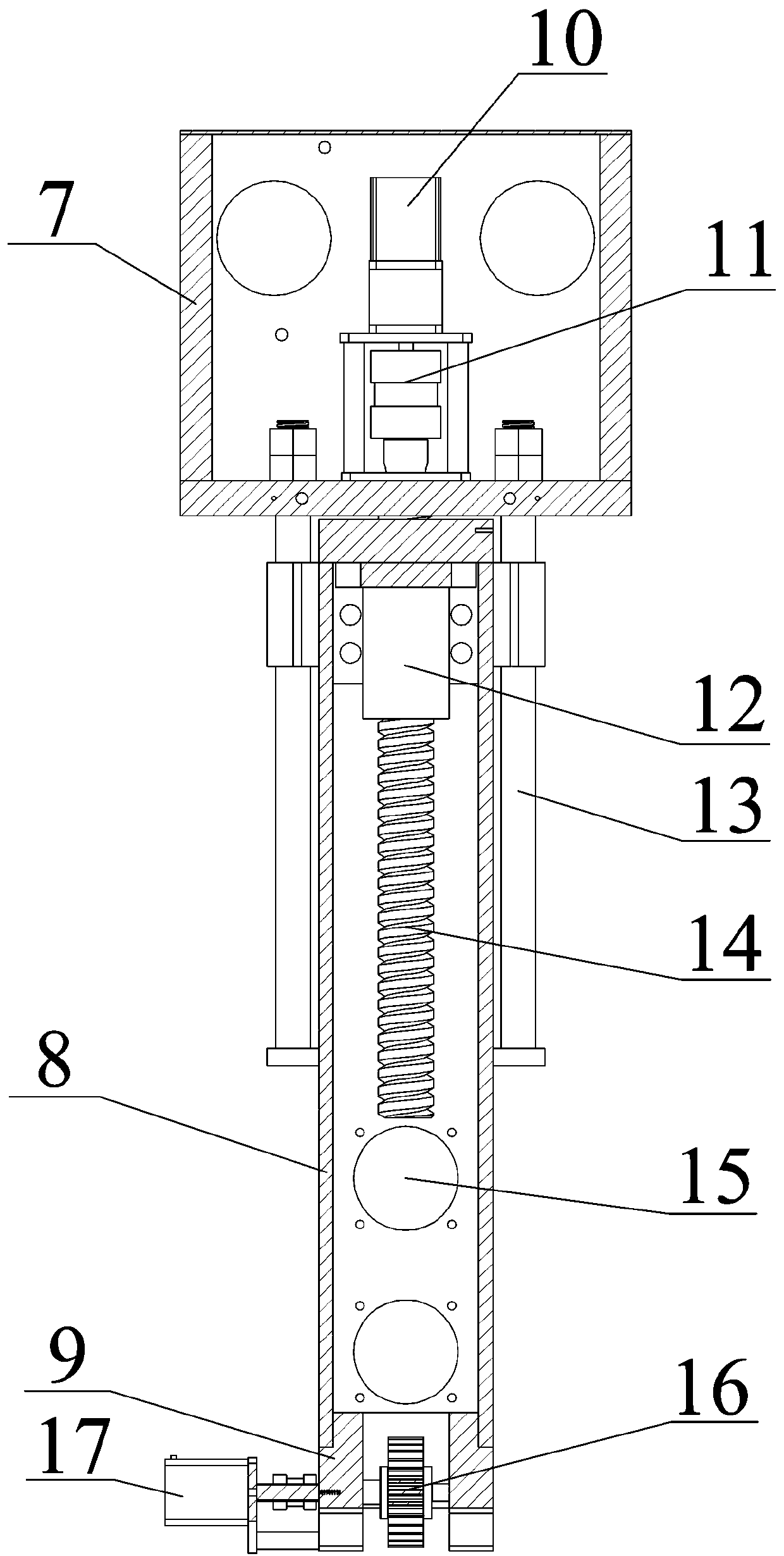

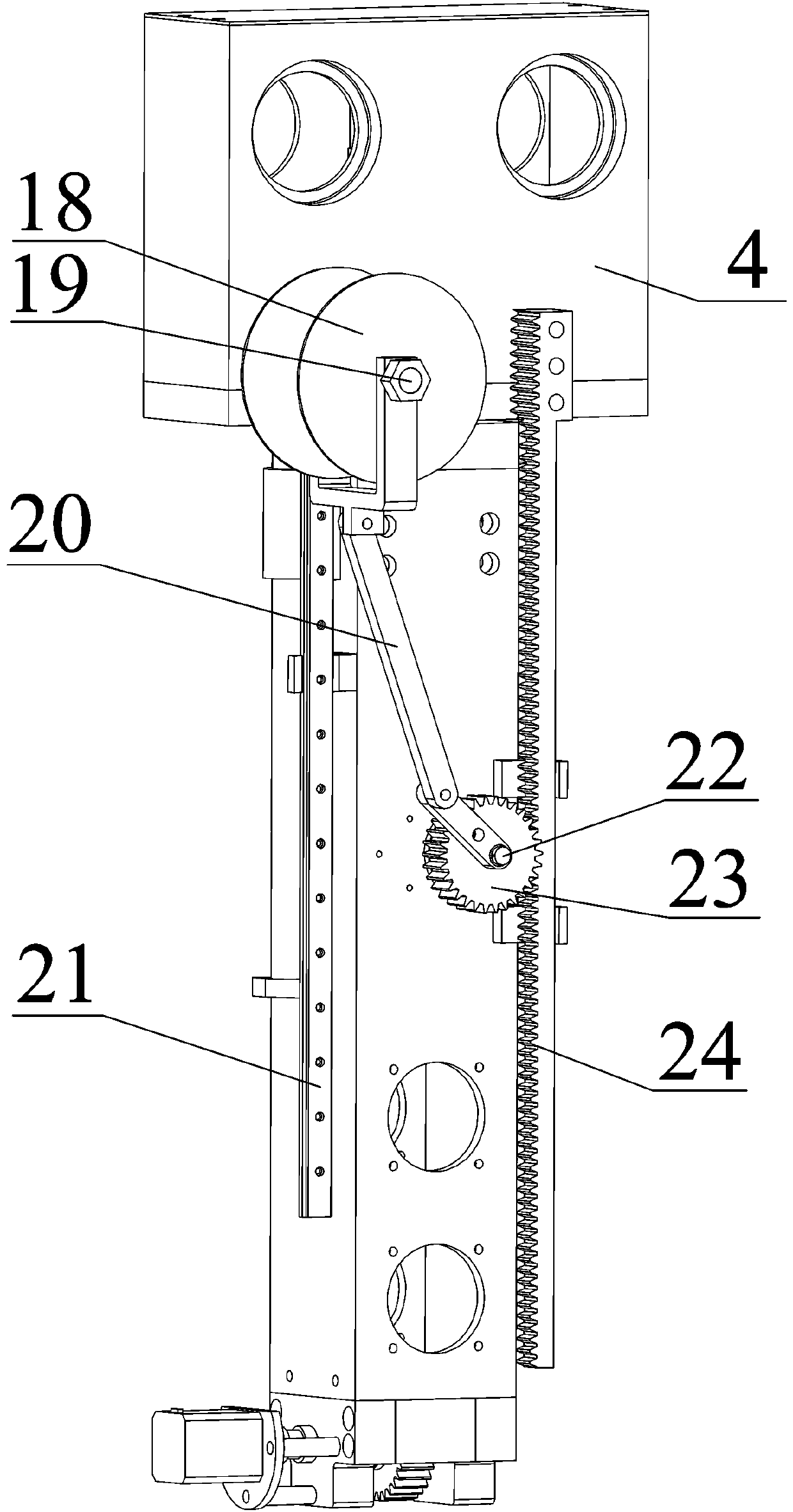

[0034] Such as figure 1 As shown, a high-voltage transmission line rescue robot is composed of a braking mechanism 1, a traveling mechanism 2, a clamping mechanism 3, a mechanical arm 4, a support frame 5 and a hanging basket 6. Wherein, the mechanical arm 4 is composed of three parts: the upper part 7 of the mechanical arm, the middle part 8 of the mechanical arm and the lower part 9 of the mechanical arm; The clamping and loosening of the wires; the traveling mechanism 2 is installed on the upper part 7 of the mechanical arm to drive the whole robot to travel on the wires; the brake mechanism 1 is installed on the side of the upper part 7 of the mechanical arm. Three groups of mechanical arms 4 are installed side by side on the support frame 5, and the left and right movement of the mechanical arm 4 is realized by the gear 16 and the rack 45 between the mechanical arm bottom 9 and the support frame 5. Hanging basket 6 is a place for personnel to stay.

[0035] Such as fi...

Embodiment 2

[0042] The method for using the high-voltage transmission line rescue robot includes the following steps:

[0043] Step 1, when a dangerous situation occurs, quickly transport the rescue robot body and the hanging basket 6 to the pole tower closest to the operator's drop point;

[0044] In the second step, the rescue robot body and the hanging basket 6 are assembled together, and the screw motor 10 is started to make the upper part 8 of the mechanical arm rise for a certain distance. At this time, the traveling wheel 31 and the clamping wheel 18 will be separated due to the linkage effect;

[0045] Step 3, use the hoisting device to hoist the rescue robot on the high-voltage transmission line. After the traveling wheel 31 is hung on the line, start the screw motor 10, and clamp the wire between the traveling wheel 31 and the clamping wheel 18;

[0046] Step 4: Start the walking wheel motor 27 to allow the rescue robot to move towards the fallen worker. When encountering an obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com