Activated sludge treatment equipment loaded with magnetic powder

A technology of activated sludge and treatment equipment, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, biological water/sewage treatment, etc., can solve the waste of magnetic powder, limited treatment effect, and influence on secondary sedimentation Problems such as the sedimentation effect of the pond, to improve the treatment effect and reduce the consumption of magnetic powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

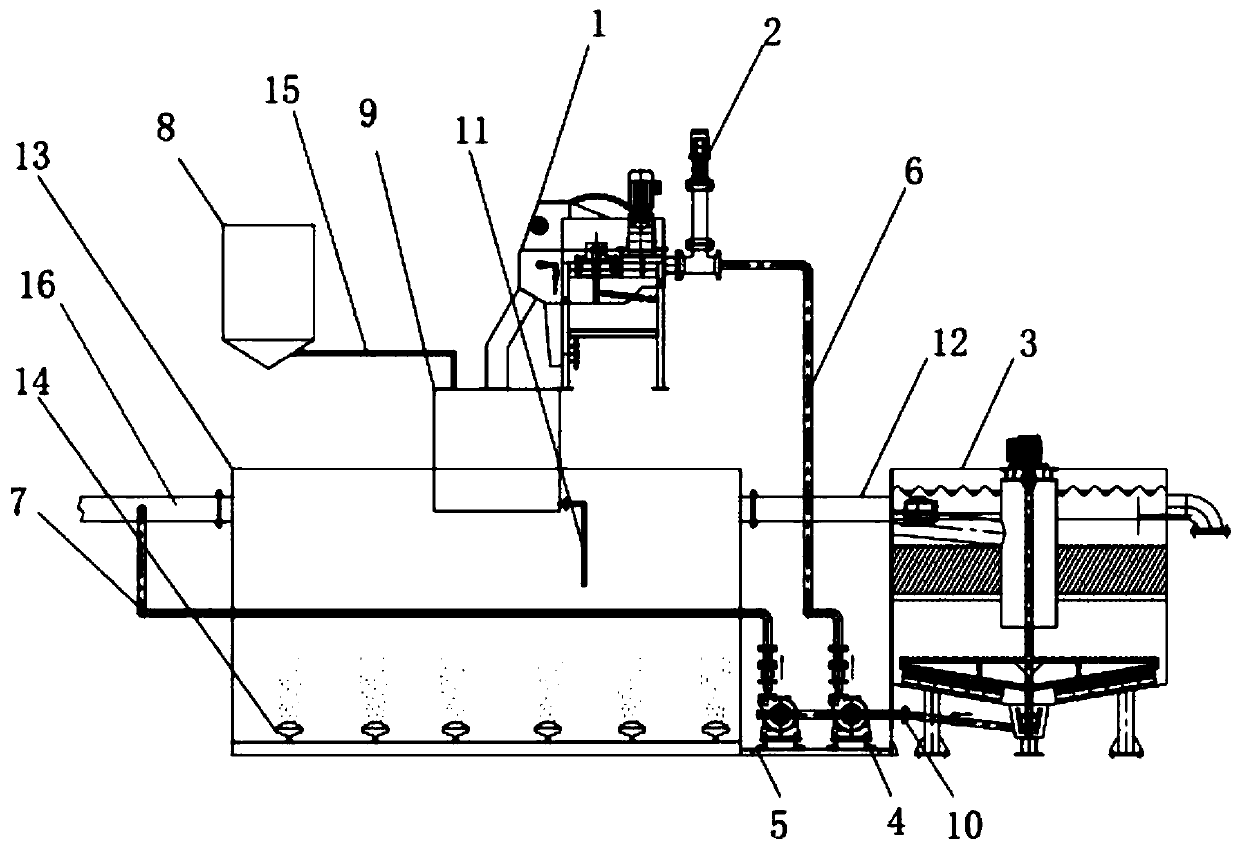

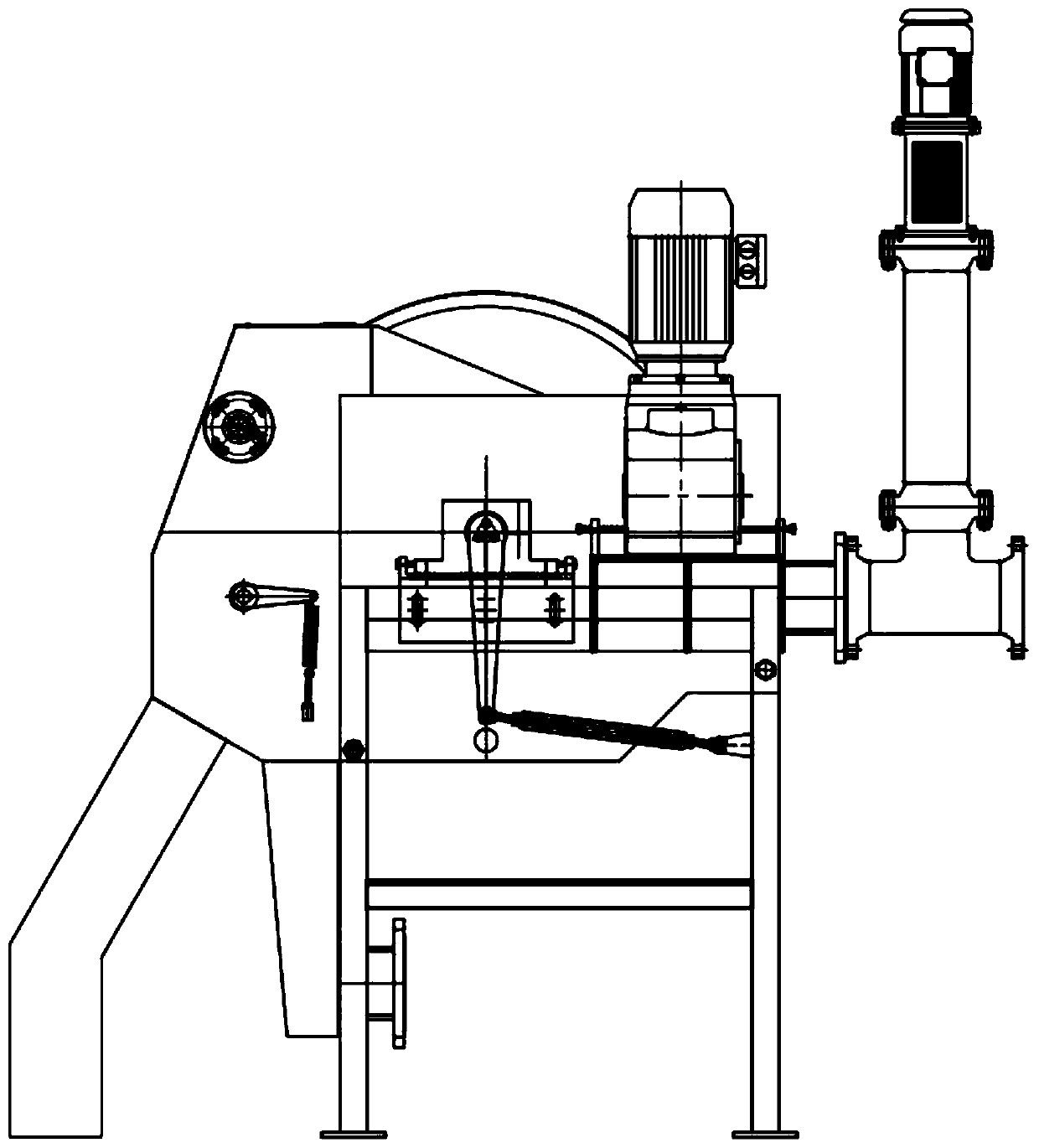

[0015] see figure 1 and figure 2 , activated sludge treatment equipment loaded with magnetic powder, including magnetic separator 1, high shear machine 2, magnetic coagulation sedimentation tank 3, excess sludge pump 4, sludge return pump 5, magnetic powder preparation tank 8, magnetic powder addition tank 9 , Aeration tank 13.

[0016] The aeration tank 13 is connected to the magnetic coagulation sedimentation tank 3 through the third pipeline 12, and the fourth pipeline 12 is arranged horizontally.

[0017] The magnetic coagulation sedimentation tank 3 is connected with the excess sludge pump 4 and the sludge return pump 5 through the sludge return pipeline 10 .

[0018] The sludge return pump 5 is connected to the outlet pipe 16 of the primary sedimentation tank through the first pipeline 7 , and the sludge return pump 5 discharges the sewage containing sludge into the outlet pipe 16 of the primary sedimentation tank.

[0019] The excess sludge pump 4 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com