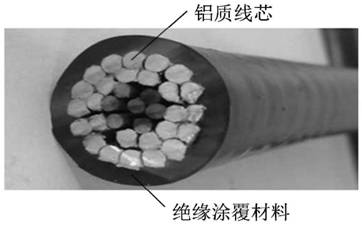

A light self-curing electrical insulation coating material, preparation method and power line

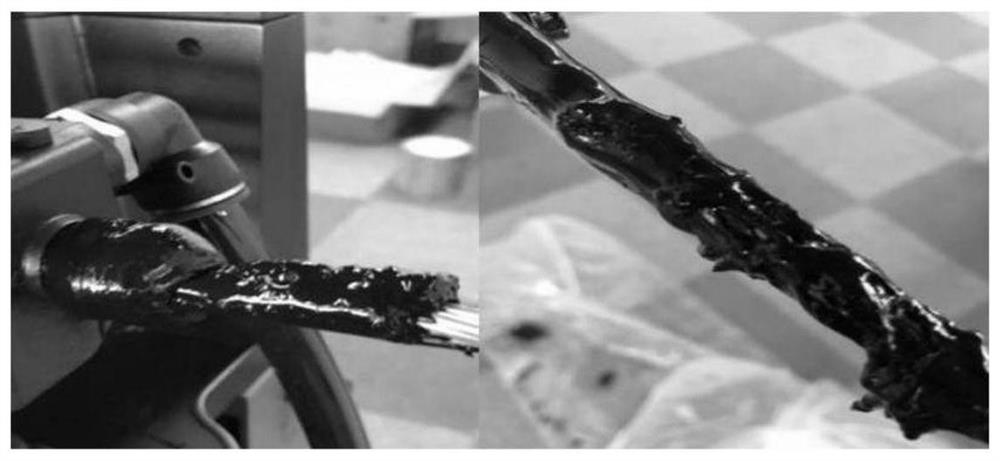

A self-curing, insulating coating technology, applied in the direction of power cables, insulated cables, power cables for overhead applications, etc., can solve problems such as only suitable for ready-to-use, short shelf life, chemical corrosion of copper and aluminum wires, etc., to achieve viscosity And thixotropy control is reasonable, the shape is stable, and the effect of improving feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the insulating coating material of the present embodiment is as follows:

[0039] By weight, 65 parts of α with a number average molecular weight of 80000, ω dimethoxy modified silicone resin, 6 parts of dimethyl silicone oil, 7 parts of hydrophobic fumed silica, 0.5 parts of chlorothalonil, 0.8 parts After the super wear-resistant carbon black is fully dispersed and uniform by the three-roll mill, it is transferred to the planetary double power mixer, and 20 parts of sphericity 97%, antistatic pressure 12Mpa, median particle size 60um, true density 0.20g are added at the same time / cm 3 Nano hollow glass microspheres, completely remove the water vapor in the material under vacuum heating and stirring environment, then slowly add 0.4 parts of hexamethyldisilazane, 1.5 parts of aminopropyltrimethoxysilane, 3 parts of methyl trimethyl A liquid mixture composed of oxysilane crosslinking agent and 1 part of bis(ethyl acetoacetate) diisopropyl tita...

Embodiment 2

[0042] The preparation method of the insulating coating material of the present embodiment is as follows:

[0043] By weight, 75 parts of α with a number average molecular weight of 100000, ω dimethoxy modified silicone resin, 7 parts of dimethyl silicone oil, 5 parts of hydrophobic fumed silica, 1 part of carbendazim, 0.4 parts After the super wear-resistant carbon black is fully dispersed and uniform by the three-roll mill, it is transferred to the planetary double power mixer, and 22 parts of sphericity 95%, antistatic pressure 30Mpa, median particle size 45um, true density 0.49g are added at the same time / cm 3Nano hollow glass microspheres, completely remove the water vapor in the material under vacuum heating and stirring environment, then slowly add 0.5 parts of ultrafine anhydrous calcium chloride, 1 part of glycidyl ether propyl triethylsilane, 2 parts A mixture of methyltrimethoxysilane crosslinking agent and 0.7 parts of bis(ethyl acetoacetate) diisopropyl titanate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com