Heat-absorbing shading waterproof oil-proof antifouling curtain fabric and preparation method thereof

A waterproof, oil-proof, and anti-fouling technology, which is applied in glass manufacturing equipment, anti-coloring pollution/anti-fouling fibers, manufacturing tools, etc., can solve the problems of inconvenient cleaning and poor heat absorption function, and achieve good waterproof performance and durability Strong stain resistance, good waterproof, oil-proof and anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

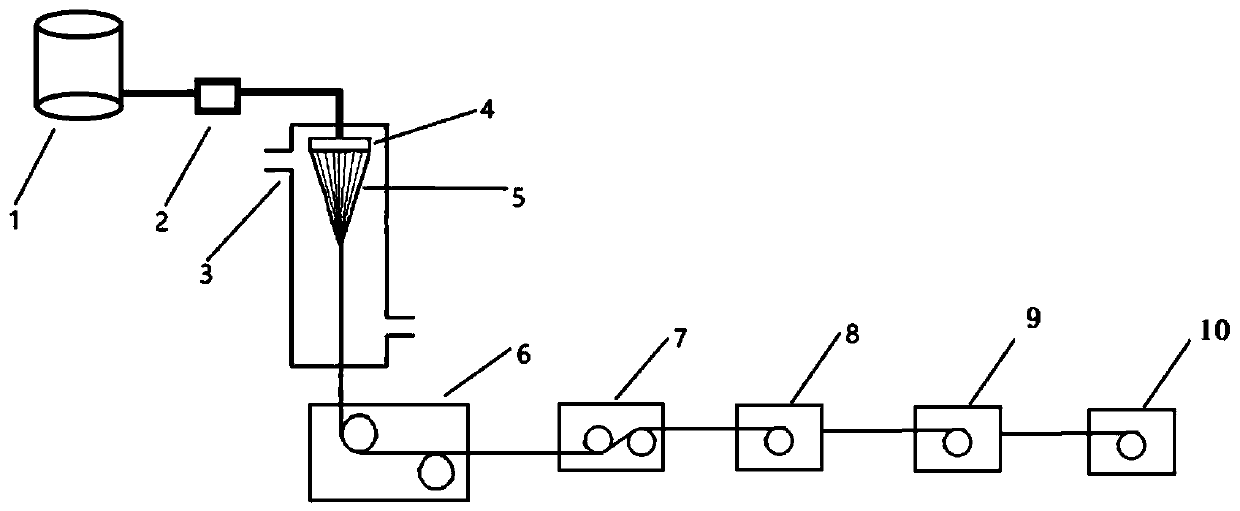

Method used

Image

Examples

Embodiment 1

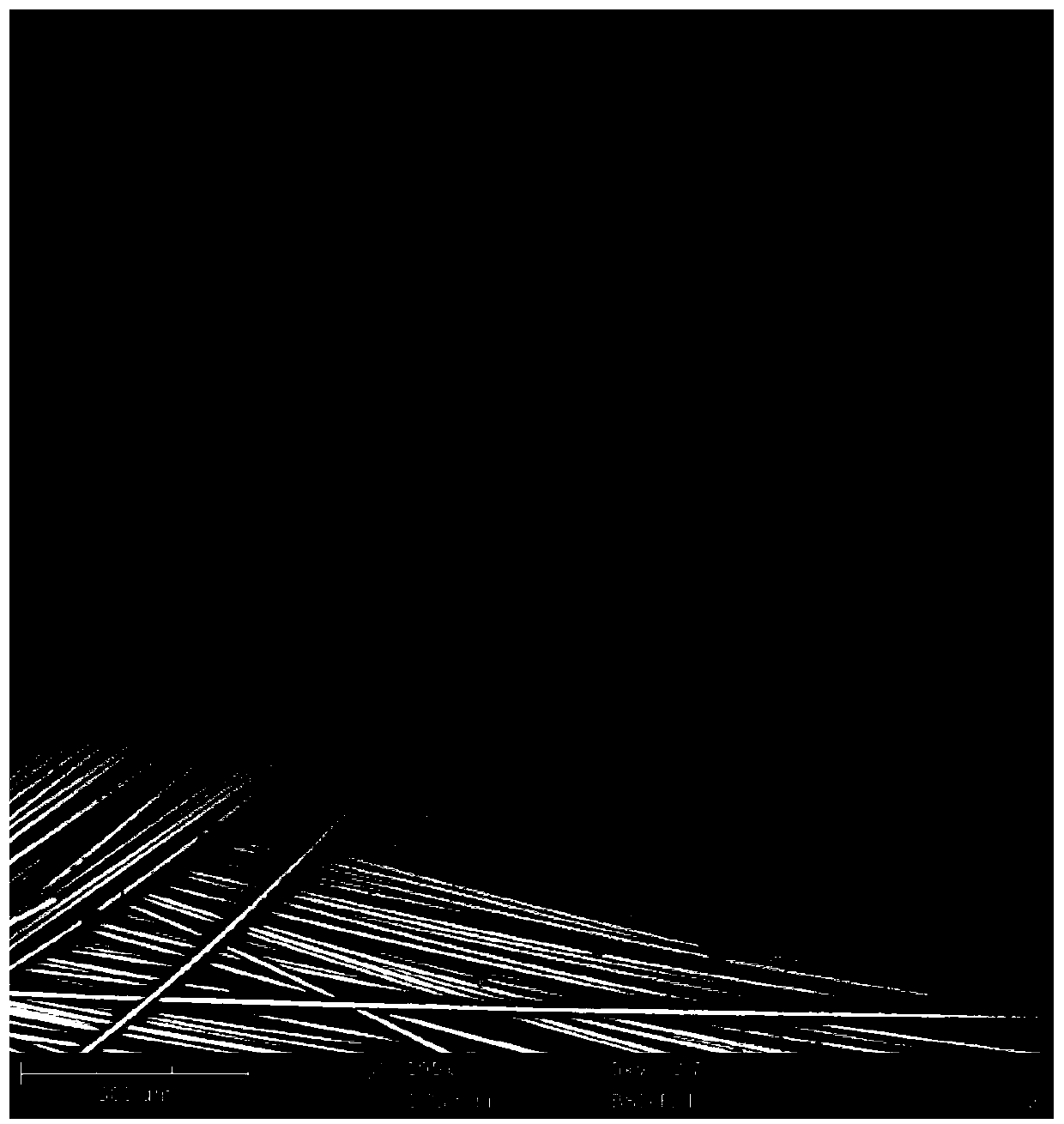

[0029] In this embodiment, a method for preparing heat-absorbing, light-shielding, water-repellent, oil-repellent and anti-fouling curtain fabric includes the following steps:

[0030] (1)ZrO 2 -TiO 2 Preparation of sol: Weigh 10g zirconium nitrate pentahydrate and dissolve it in 300mL absolute ethanol to prepare mixed solution a; Weigh 20mL tetrabutyl titanate and dissolve it in 300mL absolute ethanol to prepare mixed solution b ; Mix 20 mL of mixed solution a and 300 mL of mixed solution b uniformly to prepare mixed solution c; dissolve 150 mL of deionized water and 30 mL of 10% aqueous hydrochloric acid in 300 mL of absolute ethanol to prepare mixed solution d; add mixed solution d until stirring The mixed solution c, the dripping time is 2 hours, after the dripping, continue to stir for 3 hours to prepare the initial ZrO 2 -TiO 2 Sol; put it at 30℃ for 6 hours, when its viscosity reaches 55.6Pa·s, the ZrO to be spun is obtained 2 -TiO 2 Sol.

[0031] (2)ZrO 2 -TiO 2 Preparation...

Embodiment 2

[0035] In this embodiment, a method for preparing heat-absorbing, light-shielding, water-repellent, oil-repellent and anti-fouling curtain fabric includes the following steps:

[0036] (1)ZrO 2 -TiO 2 Preparation of sol: Weigh 10g of zirconium nitrate pentahydrate and dissolve it in 200mL of absolute ethanol to prepare mixed solution a; Weigh 20mL of tetrabutyl titanate and dissolve it in 200mL of absolute ethanol to prepare mixed solution b ; Mix 20 mL of mixed solution a and 200 mL of mixed solution b uniformly to prepare mixed solution c; dissolve 100 mL of deionized water and 20 mL of 10% aqueous hydrochloric acid in 200 mL of absolute ethanol to prepare mixed solution d; add mixed solution d until stirring The mixed solution c, the dripping time is 2 hours, after the dripping, continue to stir for 3 hours to prepare the initial ZrO 2 -TiO 2 Sol; put it at 20℃ for 4 hours, when its viscosity reaches 38.9Pa·s, the ZrO to be spun is obtained 2 -TiO 2 Sol.

[0037] (2)ZrO 2 -TiO 2...

Embodiment 3

[0041] In this embodiment, a method for preparing heat-absorbing, light-shielding, water-repellent, oil-repellent and anti-fouling curtain fabric includes the following steps:

[0042] (1)ZrO 2 -TiO 2 Preparation of sol: Weigh 10g of zirconium nitrate pentahydrate and dissolve it in 400mL of absolute ethanol to prepare mixed solution a; Weigh 20mL of tetrabutyl titanate and dissolve it in 400mL of absolute ethanol to prepare mixed solution b ; Mix 20 mL of mixed solution a and 400 mL of mixed solution b uniformly to prepare mixed solution c; dissolve 200 mL of deionized water and 40 mL of 10% aqueous hydrochloric acid in 400 mL of absolute ethanol to prepare mixed solution d; add mixed solution d until stirring The mixed solution c, the dripping time is 3 hours, after the dripping, continue to stir for 4 hours to prepare the initial ZrO 2 -TiO 2 Sol; put it at 40℃ for 8 hours, when its viscosity reaches 66.8Pa·s, the ZrO to be spun is obtained 2 -TiO 2 Sol.

[0043] (2)ZrO 2 -TiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com