A self-cleaning anti-static high temperature resistant filter bag fabric and preparation method thereof

An anti-static, high-temperature-resistant technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as complex preparation processes, achieve the effects of wide source of raw materials, improved self-cleaning performance, and low reflection coefficient decline rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, a method for preparing a self-cleaning and antistatic high temperature resistant filter bag fabric comprises the following steps:

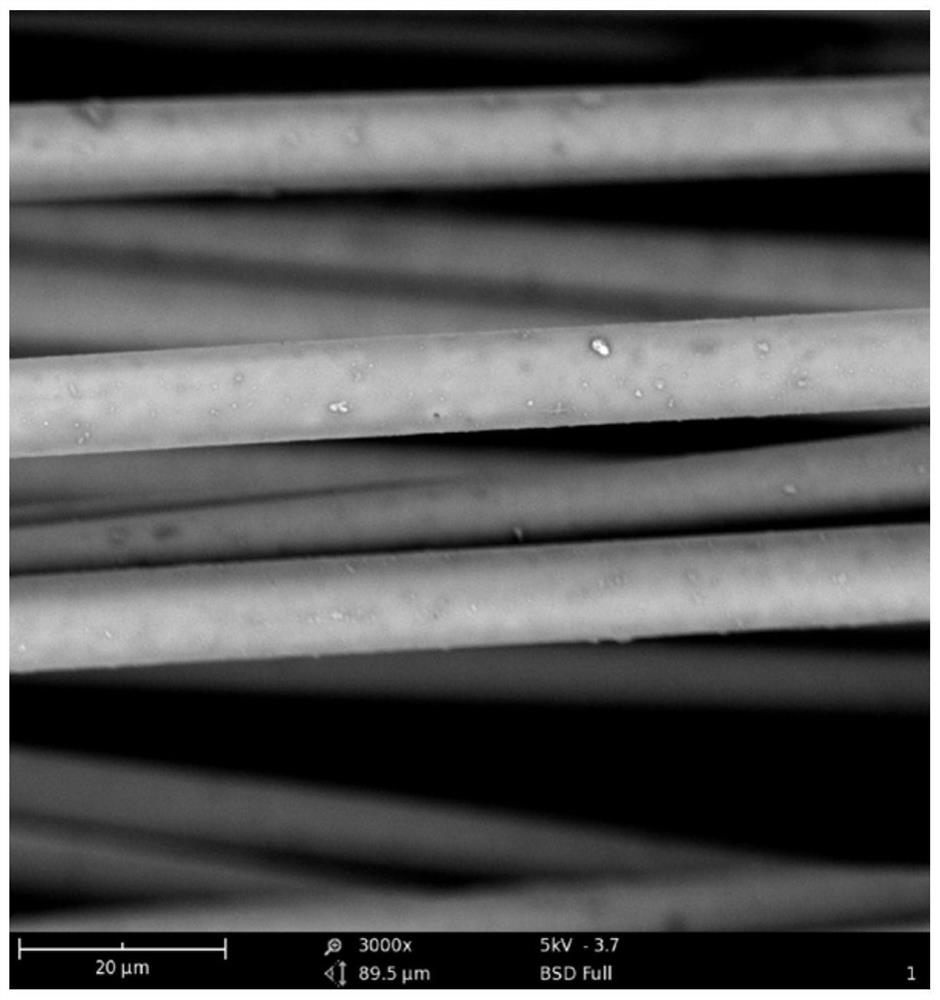

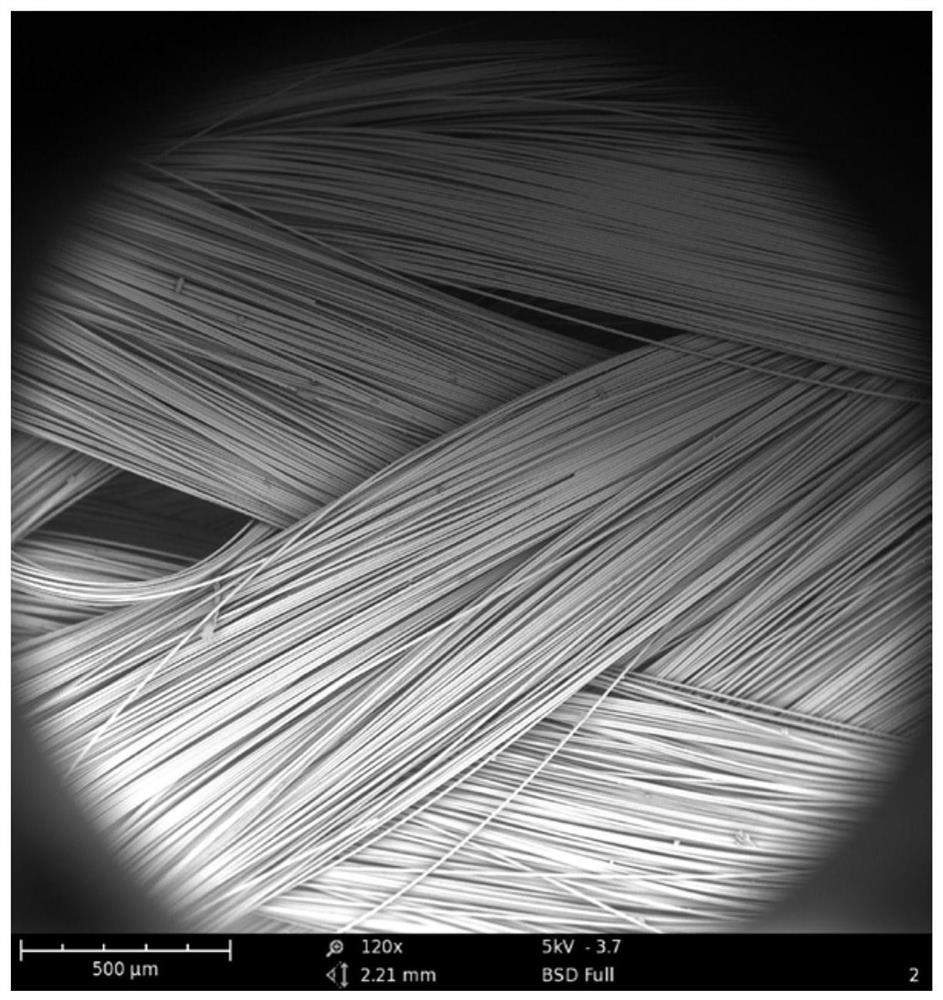

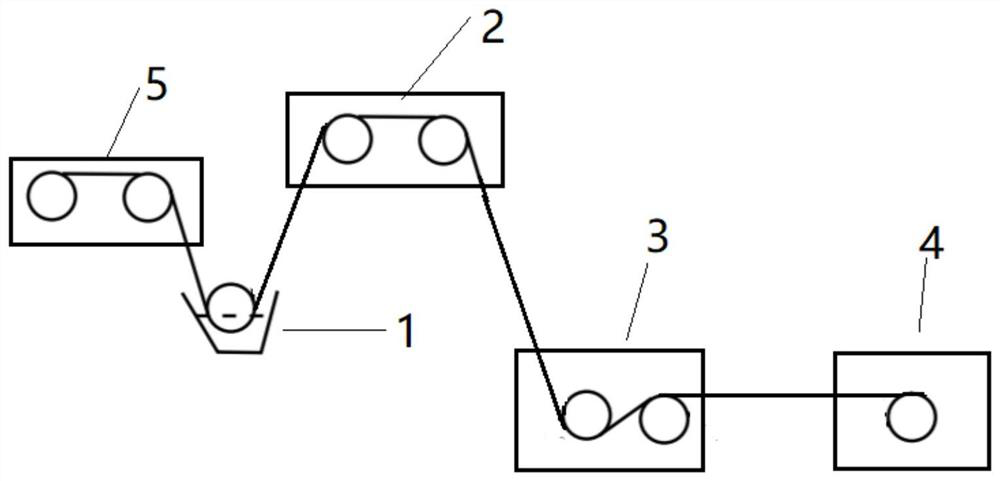

[0028] (1) Preparation of TiN ceramic fiber: Weigh 10mL of titanium tetrachloride and 150mL of isopropanol and react at 60°C for 4 hours to prepare titanium isopropoxide (Ti(O i C 3 h 7 ) 4 ); Dissolve 20mL of titanium isopropoxide in 300mL of absolute ethanol to prepare a mixed solution a; dissolve 10mL of 10% hydrochloric acid and 150mL of deionized water in 250mL of absolute ethanol to prepare a mixed solution b; add the mixed solution b dropwise to Stirring the mixed solution a, adding it dropwise for 2 hours, to obtain the initial titanium sol; place it at 30° C. for 4 hours, and when the viscosity reaches 55.8 Pa·s, obtain the titanium sol to be spun; The sol is added to the spinning system for spinning, and the spun threads are washed, oiled, and dried to obtain silk threads; the silk threads are dried at 70°C ...

Embodiment 2

[0033] In this embodiment, a method for preparing a self-cleaning and antistatic high temperature resistant filter bag fabric comprises the following steps:

[0034] (1) Preparation of TiN ceramic fiber: Weigh 10mL of titanium tetrachloride and 100mL of isopropanol and react at 60°C for 4 hours to prepare titanium isopropoxide (Ti(O i C 3 h 7 ) 4 ); Dissolve 20mL of titanium isopropoxide in 200mL of absolute ethanol to prepare mixed solution a; dissolve 10mL of 10% hydrochloric acid and 100mL of deionized water in 200mL of absolute ethanol to obtain mixed solution b; add dropwise mixed solution b to Stirring the mixed solution a, adding it dropwise for 2 hours, to obtain the initial titanium sol; place it at 20°C for aging for 2 hours, and when the viscosity reaches 43.6 Pa·s, obtain the titanium sol to be spun; The sol is added to the spinning system for spinning, and the spun threads are washed, oiled, and dried to obtain silk threads; the silk threads are dried at 70°C f...

Embodiment 3

[0039] In this embodiment, a method for preparing a self-cleaning and antistatic high temperature resistant filter bag fabric comprises the following steps:

[0040] (1) Preparation of TiN ceramic fiber: Weigh 10mL of titanium tetrachloride and 200mL of isopropanol and react at 60°C for 4 hours to prepare titanium isopropoxide (Ti(O i C 3 h 7 ) 4 ); Dissolve 20mL of titanium isopropoxide in 400mL of absolute ethanol to prepare a mixed solution a; dissolve 10mL of 10% hydrochloric acid and 200mL of deionized water in 300mL of absolute ethanol to prepare a mixed solution b; add the mixed solution b dropwise to Stirring the mixed solution a, adding it dropwise for 2 hours, to obtain the initial titanium sol; place it at 40°C for 6 hours, and when the viscosity reaches 89.8 Pa·s, obtain the titanium sol to be spun; The sol is added to the spinning system for spinning, and the spun threads are washed, oiled, and dried to obtain silk threads; the silk threads are dried at 70°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com