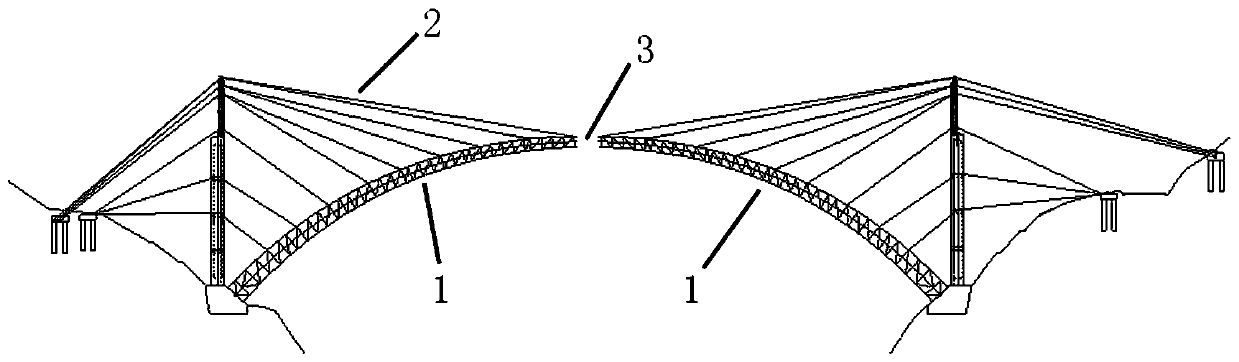

Forced closure construction method for vault of steel tube arch bridge mounted in cable-stayed buckling and cantilevered assembly mode

A steel tube arch bridge and cable-stayed buckle technology, which is applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of structural influence, rough closing process, large deviation of construction effect design goals, etc., to improve long-term service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

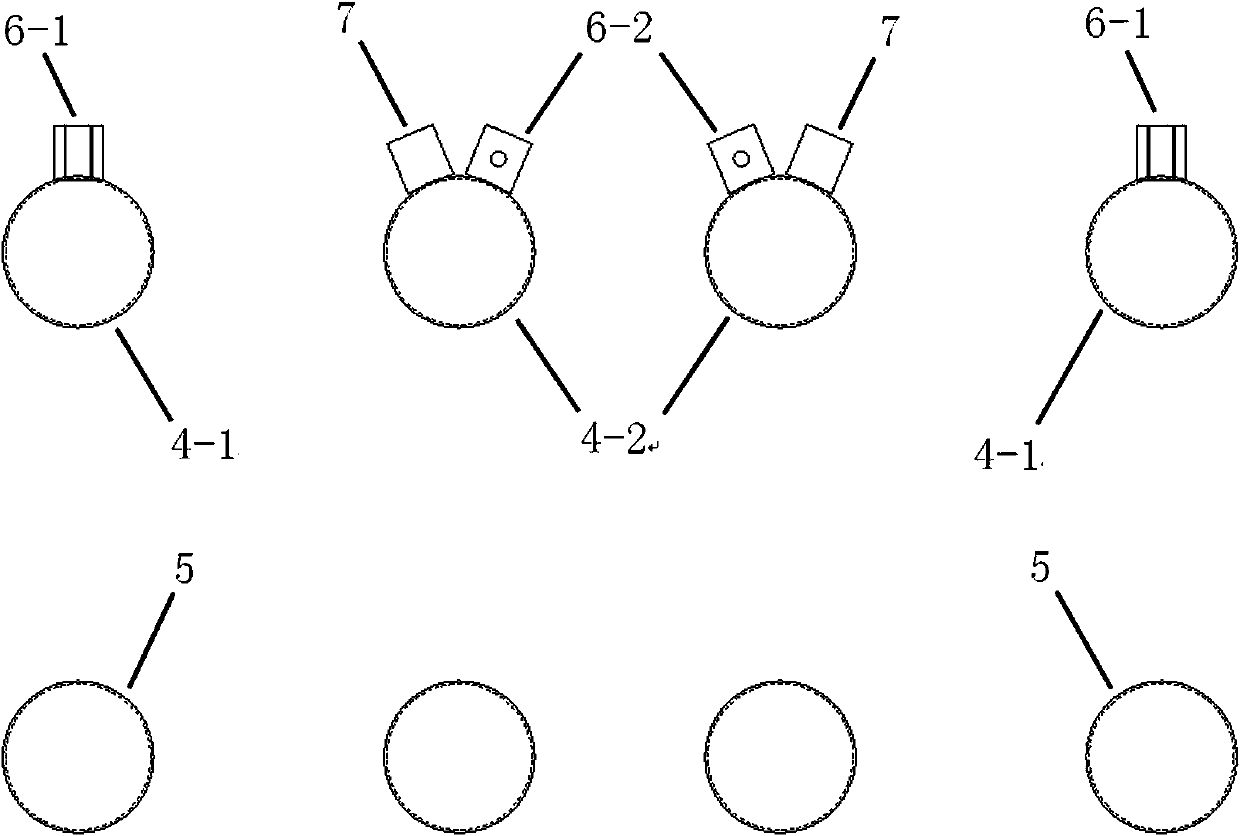

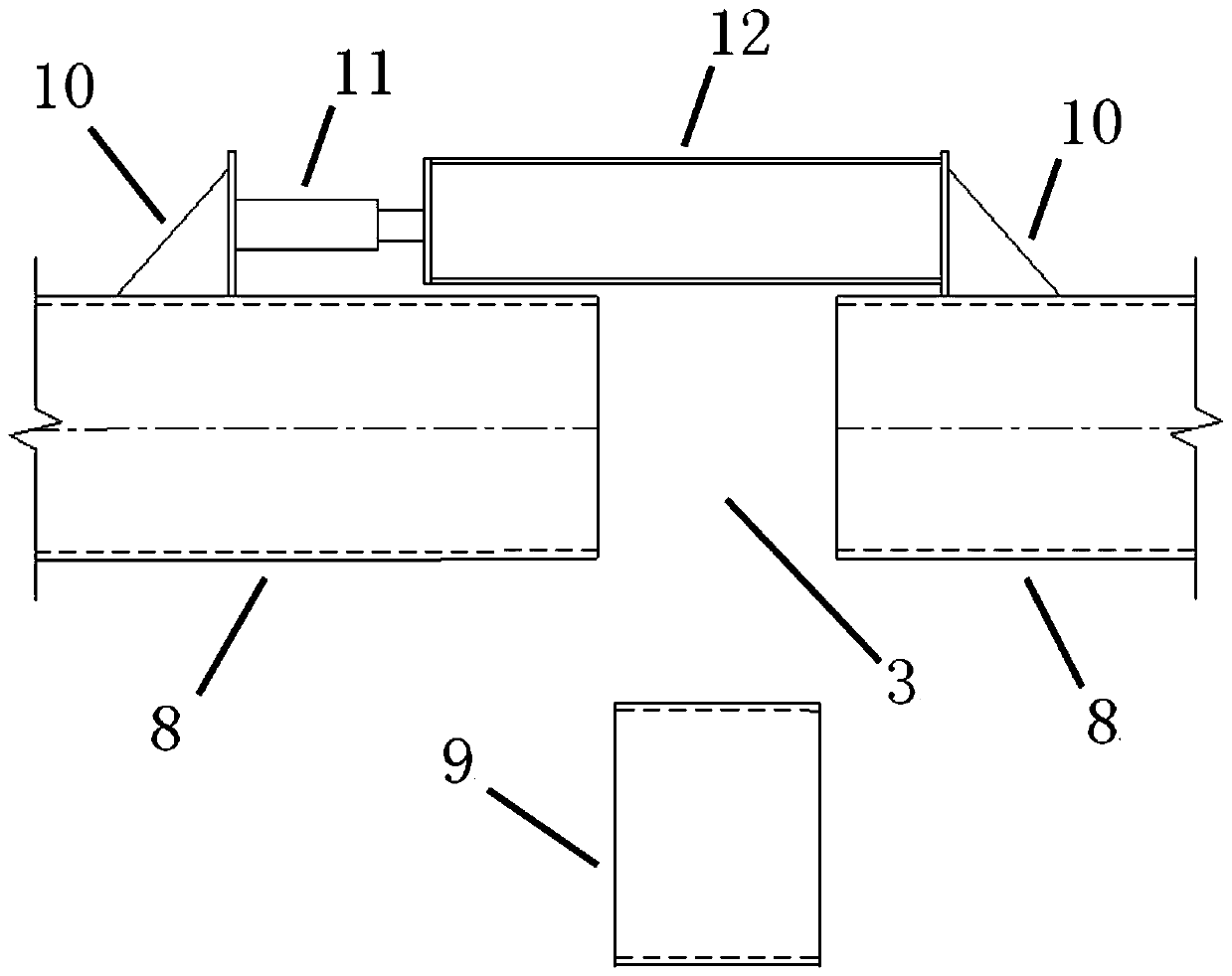

[0041] A large-span steel pipe arch bridge in a mountainous area has 8 main chord steel pipes with a diameter of φ750×24mm, 4 upper chords, and 4 lower chords. A short steel pipe with a length of 600~800mm is forced to close.

[0042] In the large cantilever state of the steel pipe arch bridge 1, the overall line shape before closing is adjusted through the fastening system 2, so that the elevation and lateral offset of the arch rib steel pipes 8 on both sides of the closing mouth 3 are controlled within the allowable range. The design requires forced closing of the vault at a temperature of 16°C. According to the actual climate conditions during the construction period, through three consecutive days of temperature observation, it is determined that the closing operation should be carried out at a time when the temperature is relatively stable at night. The average temperature during this time period is 23°C, this is the best closing temperature. Based on the predetermined c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com