Special cast-in-place pile drilling machine for road bridge construction

A technology for bridge construction and cast-in-place piles, applied in bridges, bridge construction, rotary drilling rigs, etc., can solve problems such as affecting the performance of the filling column, the inclination of the drill bit, and the unbalanced force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

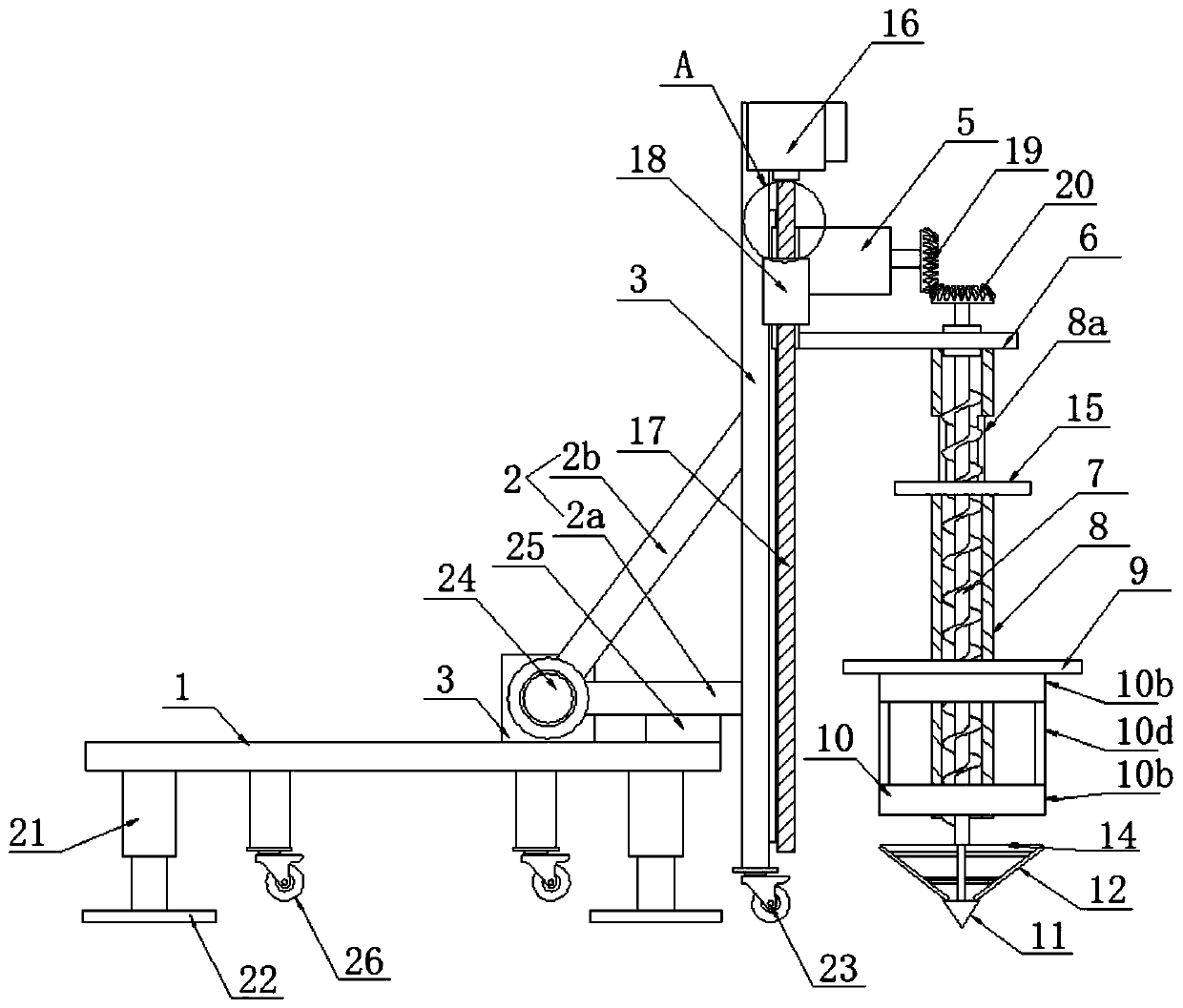

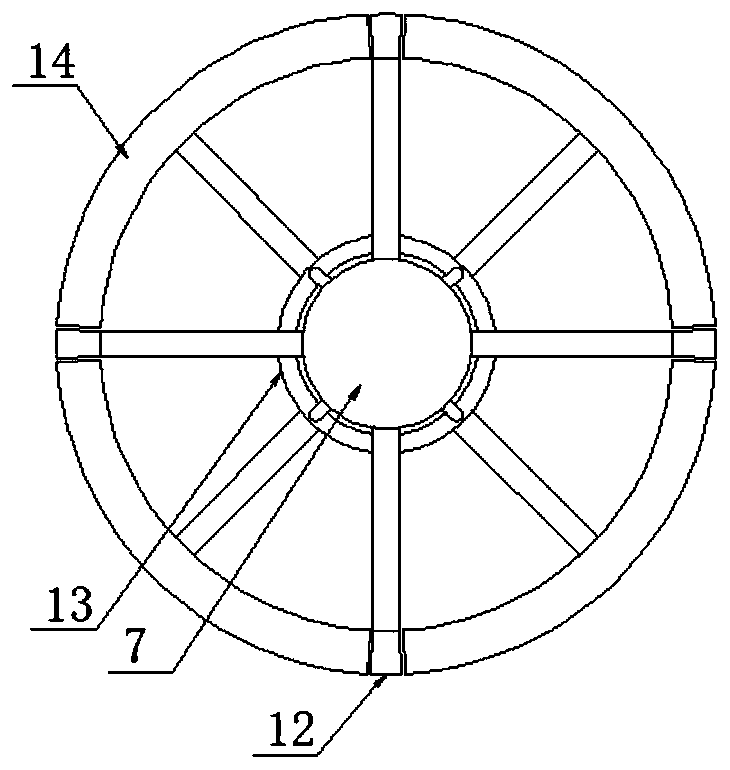

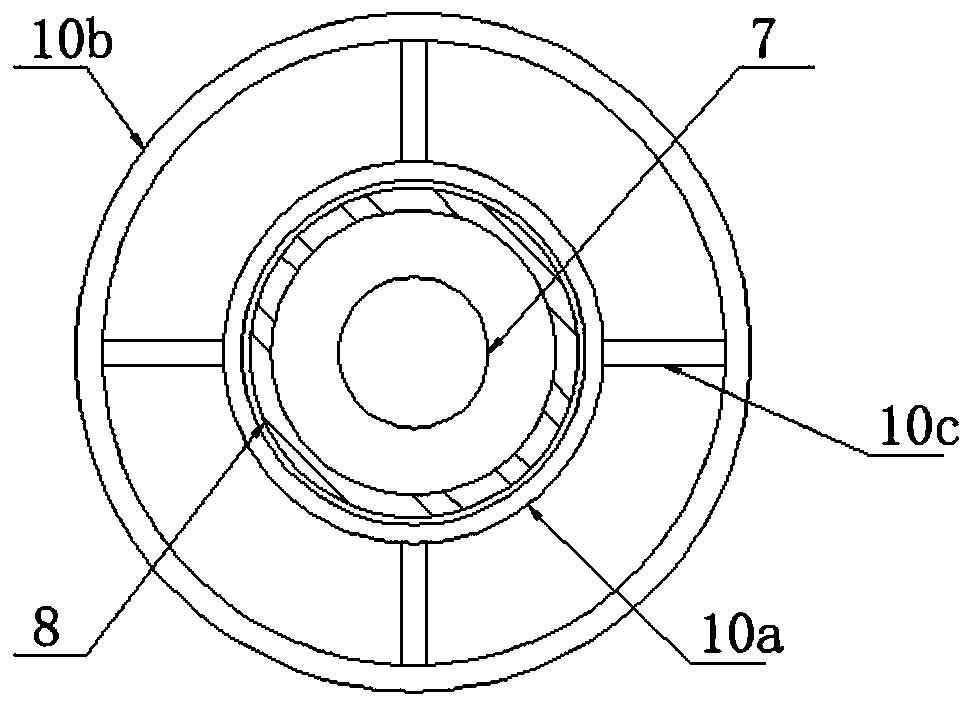

[0021] Such as figure 1 — Figure 4 As shown, a special cast-in-situ pile drilling machine for road and bridge construction is mainly composed of a fixed frame 1, a turning frame 2, a rotating plate 3, a sliding plate 4, a first motor 5, a supporting plate 6, a conveying auger 7, and a limit cylinder 8 , the first baffle plate 9, positioning cylinder 10, drill bit 11, alloy blade 12, moving ring 13, arc plate 14, second baffle plate 15, second motor 16, screw mandrel 17, threaded cylinder 18, first bevel gear 19 , second bevel gear 20, four hydraulic cylinders 21, support plate 22, support runner 23, fixed rotating shaft 24, backing plate 25, moving wheel 26 are formed.

[0022] The left side of the rotating plate 3 is connected to the fixed mount 1 through the turning frame 2, so that the rotating plate 3 can be placed on the fixed mount 1 horizontally...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap