Piston device with speed response mechanism

A technology with speed and piston, which is applied in the direction of fuel control, charging system and engine components of turbine/propulsion device, which can solve problems such as unfavorable engine ignition, sudden change of fuel supply, rich oil flameout, etc., and achieve the goal of improving the success rate of ignition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

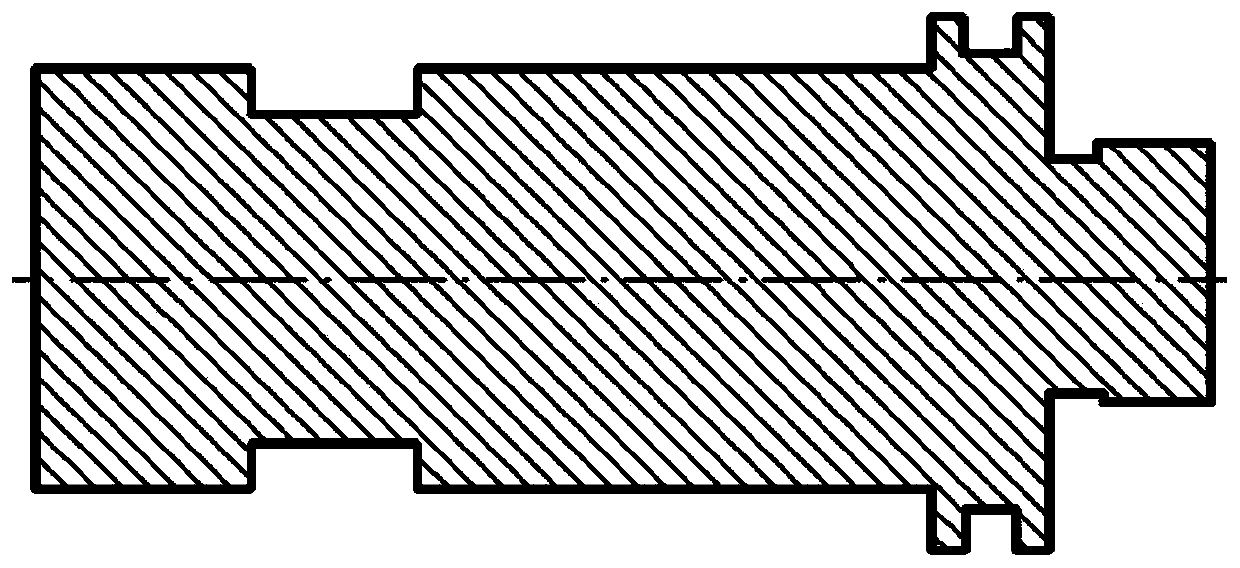

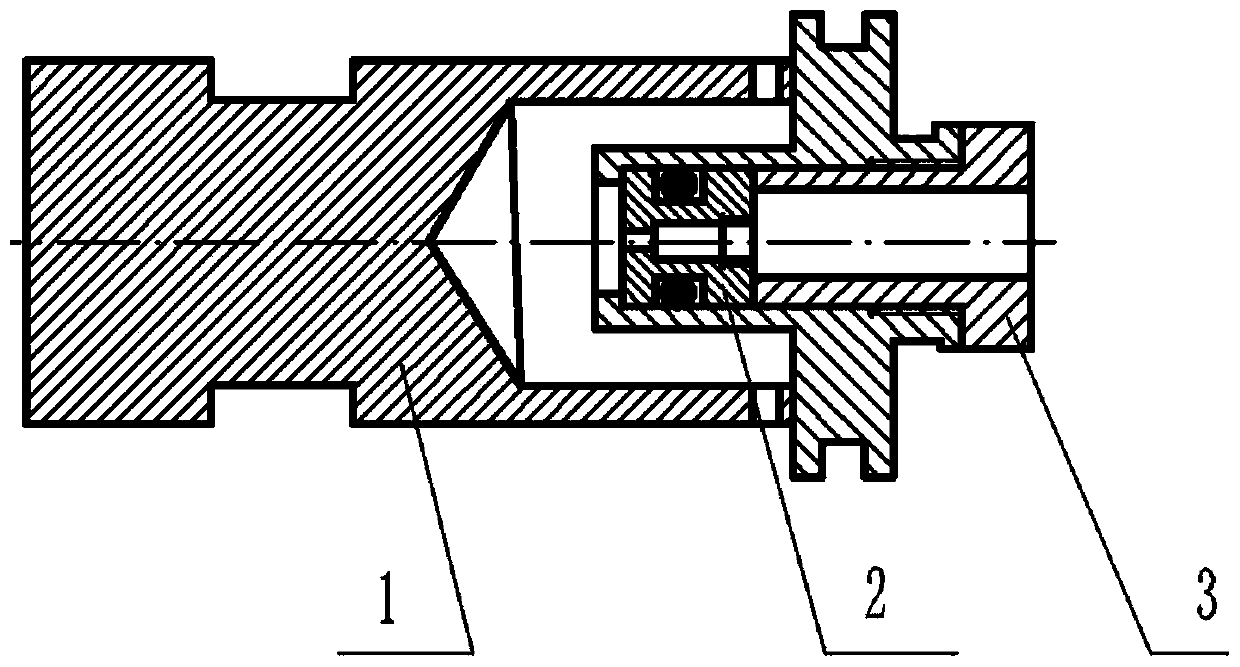

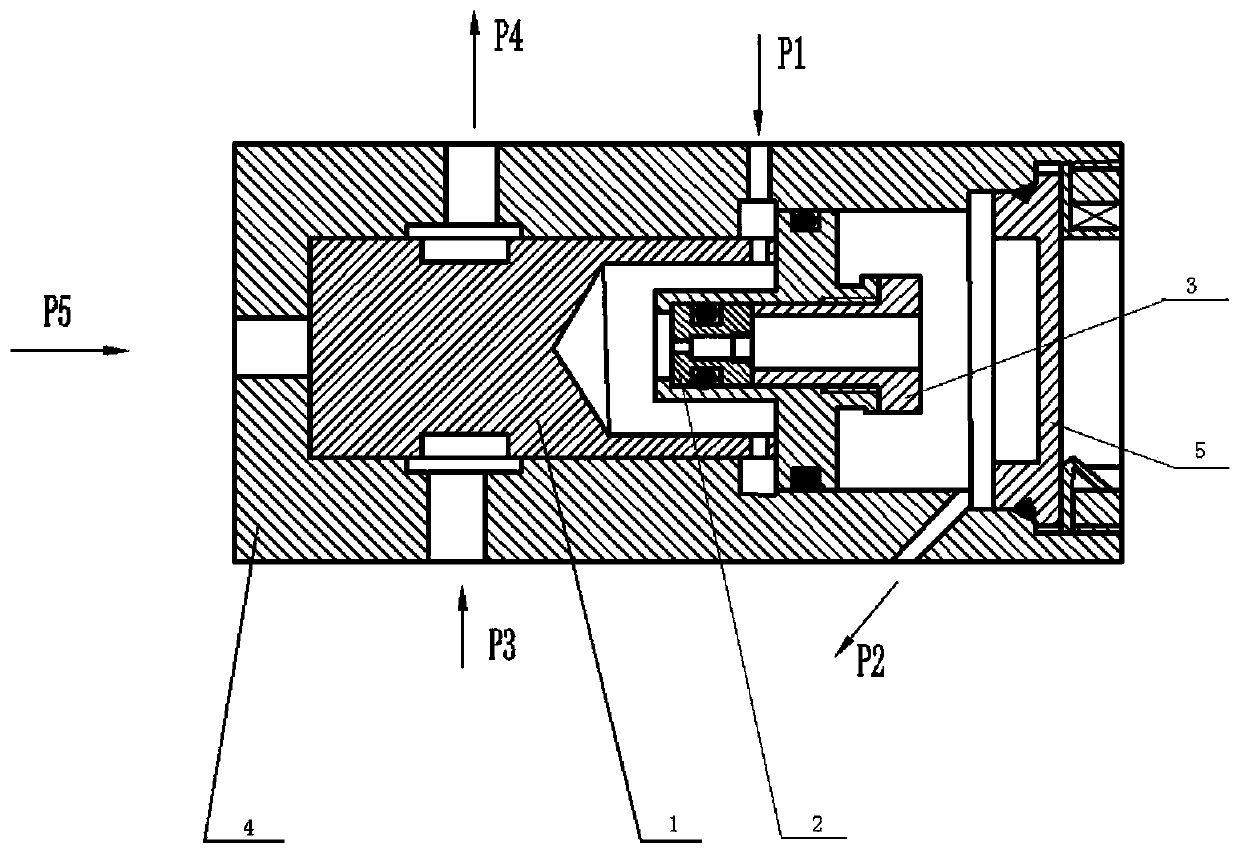

[0019] see image 3 The present invention provides a piston device with a speed response mechanism, which includes a housing 4 and a piston placed inside the housing 4 that can move along the axial direction of the housing 4. The housing 4 is provided with a working oil passage inlet P3 and The outlet of the working oil circuit is P4, and the piston is provided with a ring-shaped working oil circuit channel; the piston includes a piston head 1 and a flow-adjustable piston seat fixedly connected to the piston head 1; the housing 4 is provided with a regulating oil circuit inlet P1 and regulating oil The outlet P2 of the regulating oil circuit; the inlet P1 of the regulating oil circuit communicates with the outlet P2 of the regulating oil circuit through the flow-adjustable piston seat; Move along the axial direction of the housing 4, and when it reaches the predetermined position of the housing 4, the inlet P3 of the working oil circuit communicates with the outlet P4 of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com