A system and method for on-line real-time self-calibration of a clamp ammeter

A clamp ammeter, self-calibration technology, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve the problems that the measurement error accuracy and consistency of the clamp ammeter cannot be guaranteed, the measurement error becomes larger, and the error becomes larger, etc., to achieve The effect of improving convenience, improving accuracy, and saving rotation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

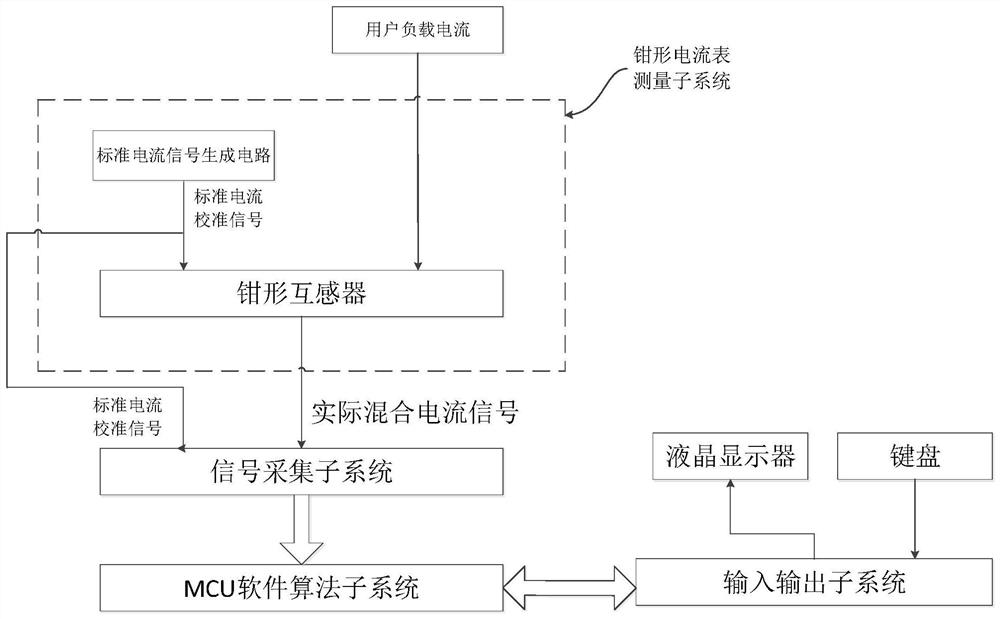

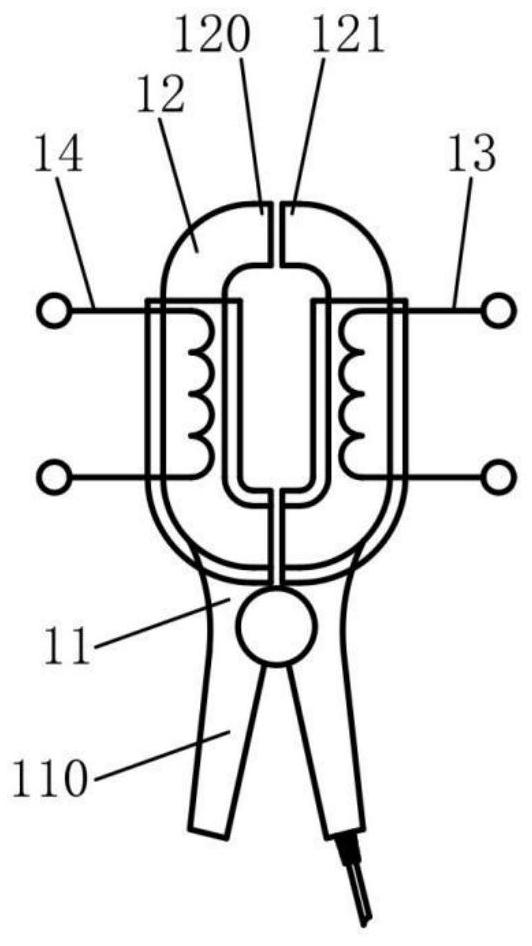

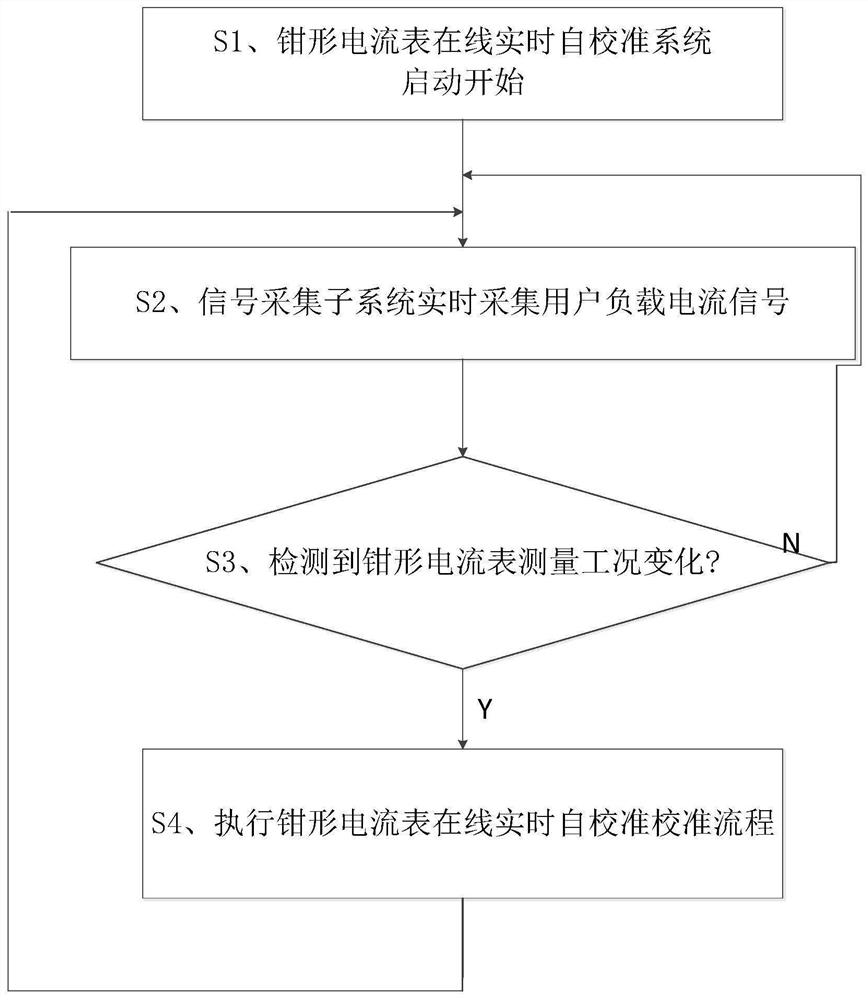

[0041] This embodiment provides an online real-time self-calibration system for a clamp ammeter, such as figure 1 As shown, it includes: a clamp-type ammeter measurement subsystem, a signal acquisition subsystem, an MCU software algorithm subsystem and an input and output subsystem; the clamp-type ammeter measurement subsystem includes a standard current signal generation circuit and a clamp-type transformer. The current signal generation circuit is used to generate the standard current calibration signal and output it to the clamp transformer and the signal acquisition subsystem. The clamp transformer is used to sample the standard current calibration signal and the user load current, and then convert the standard current calibration signal and the user load current. The actual mixed current signal obtained by mixing the signals is out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com