Reflective liquid crystal display panel

A liquid crystal display panel, reflective technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of slow response speed and low contrast of reflective liquid crystal display panels, and achieve auxiliary deflection, improve contrast, and improve response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

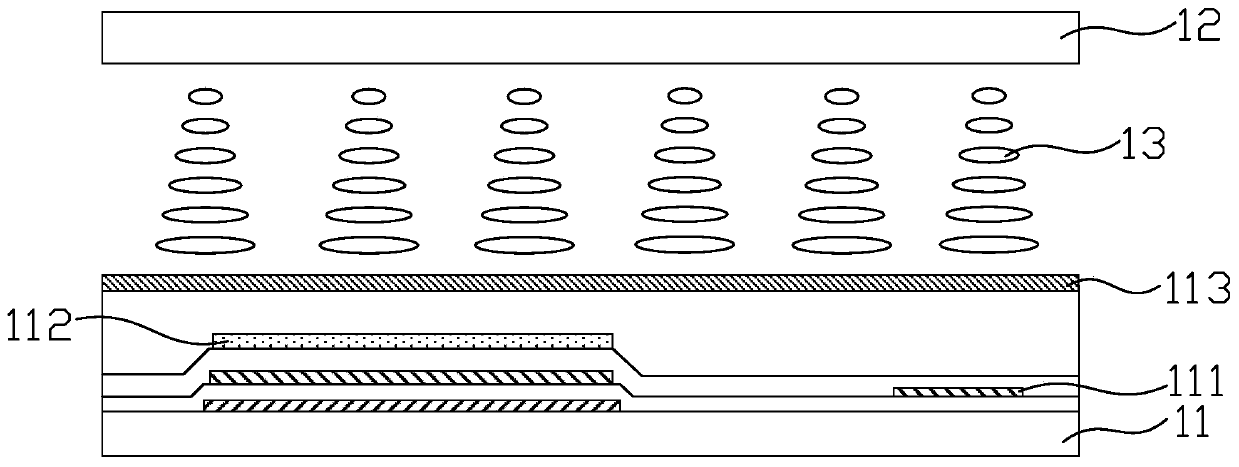

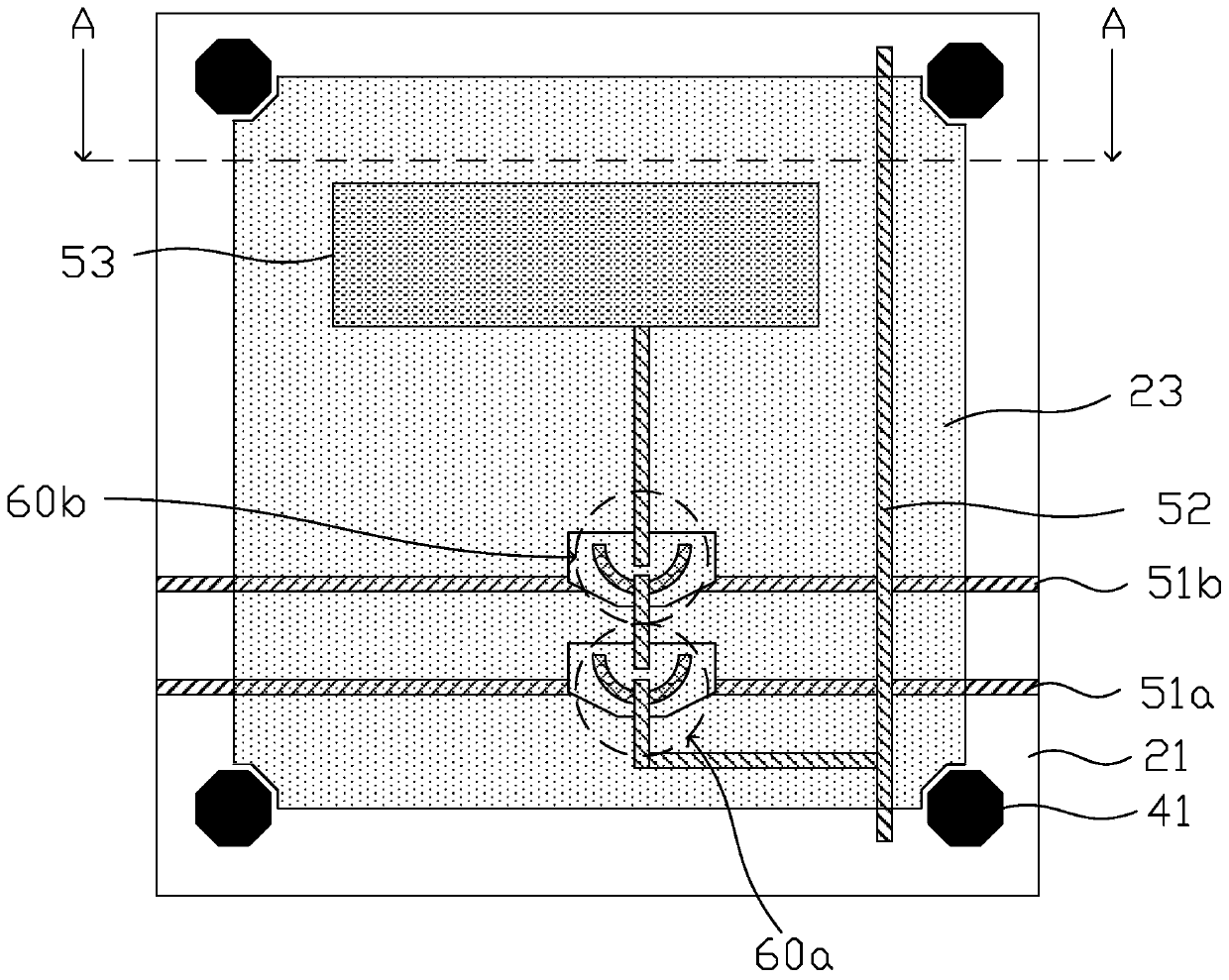

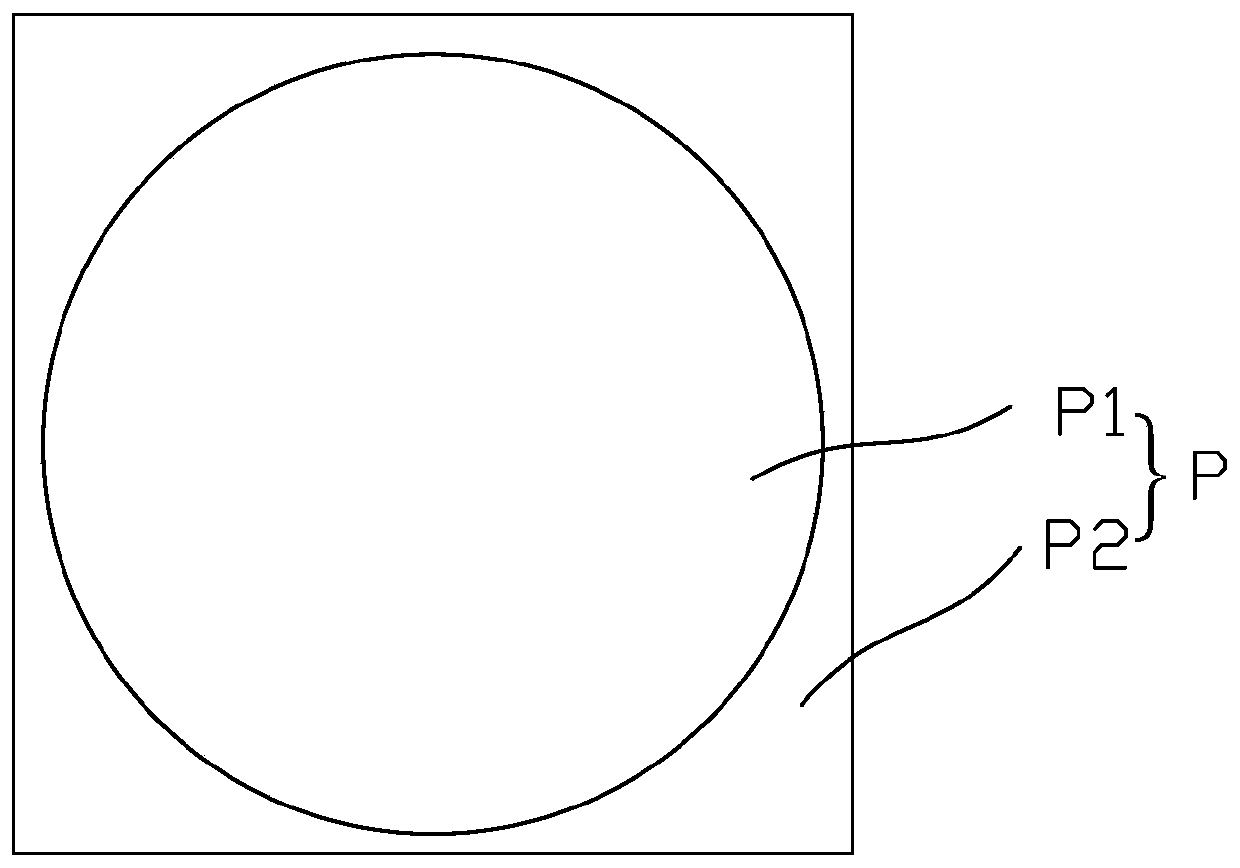

[0029] figure 2 It is a schematic diagram of the pixel structure of the reflective liquid crystal display panel according to the first embodiment of the present invention, image 3 for figure 2 A schematic diagram of partitioning of a single pixel unit P of a reflective liquid crystal display panel shown, Figure 4 for figure 2 The cross-sectional schematic diagram of the reflective liquid crystal display panel shown along the A-A section line in the dark state, please refer to Figure 2 to Figure 4 , the reflective liquid crystal display panel includes a first substrate 20 and a second substrate 30 disposed opposite to each other and a liquid crystal layer 4 between the first substrate 20 and the second substrate 30, and is provided with a plurality of pixel units P arranged in an array , each pixel unit P includes a pre-tilt region P1 and a flat region P2 disposed around the pre-tilt region P1. The first substrate 20 is provided with a common electrode 21 , a pluralit...

no. 2 example

[0040] Figure 9(a) and Figure 9(b) are schematic diagrams of the method for forming the insulating layer in the reflective liquid crystal display panel of the second embodiment of the present invention, referring to Figure 9(a) and Figure 9(b), the second embodiment of the present invention The difference between the reflective liquid crystal display panel provided in the example and the above-mentioned first embodiment is that the insulating layer 24 is formed of photocurable resin, and a part of the photocurable resin is polymerized by ultraviolet light irradiation so that the photocurable resin forms a tapered groove. The photo-curable resin includes a plurality of monomers 240 , and the photo-curable resin is first coated on the basis of forming the pixel electrode 23 , and the monomers 240 are evenly distributed in the photo-curable resin. Then set up a mask 70 (mask) above the light-curable resin, the mask 70 is provided with a light-transmitting area 71 and a non-light-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com