Pixel structure and display panel

A pixel structure, pixel electrode technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of pixel structure storage capacitance drop, overlapping area reduction, serious feed-through voltage, etc., to improve the feed-through voltage problem, low power Consume and increase the effect of storage capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

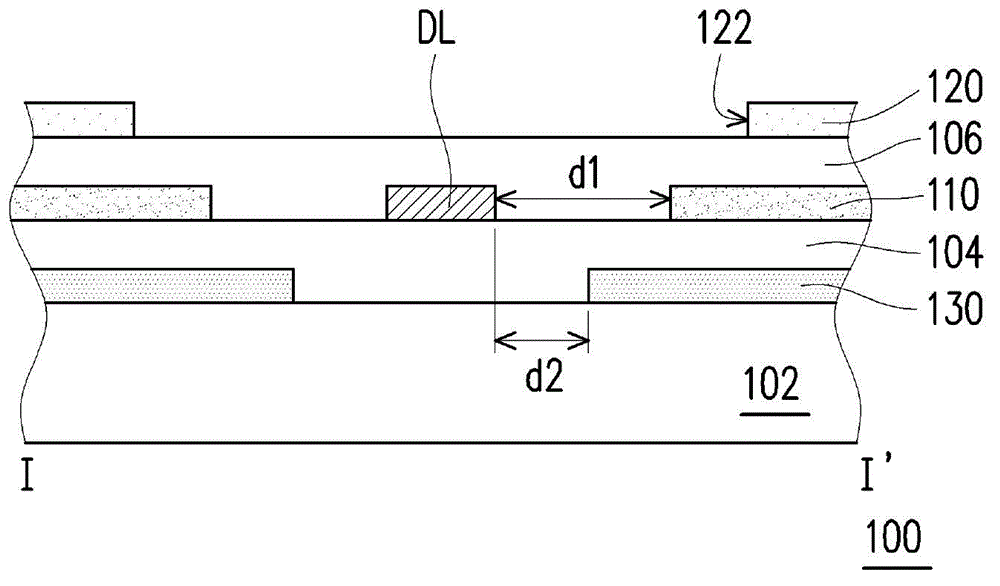

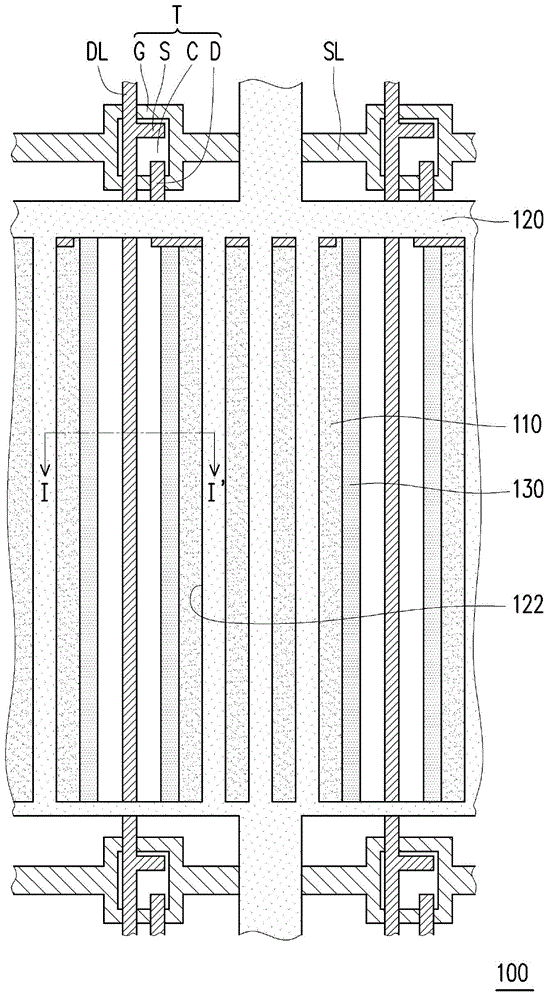

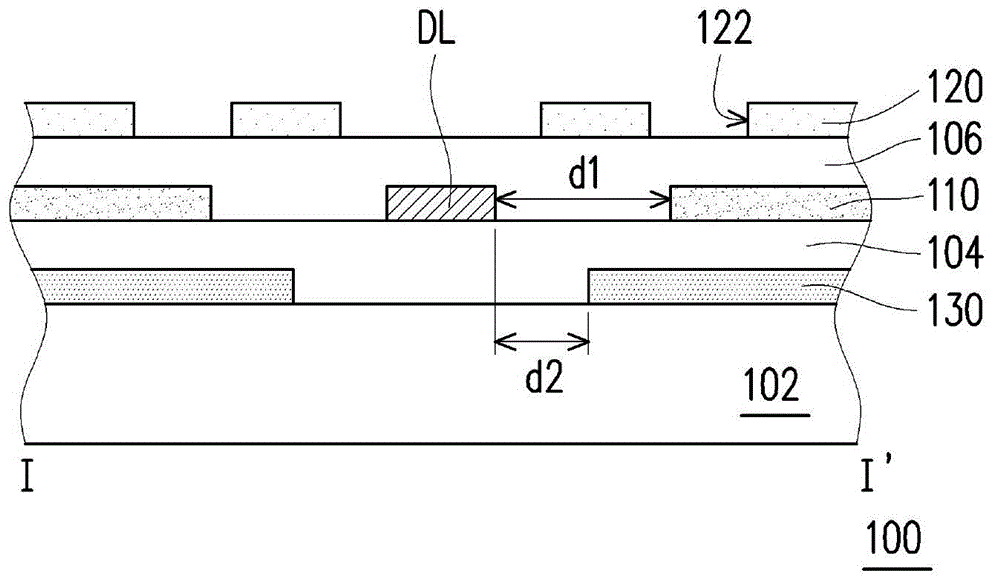

[0049] Figure 1A is a schematic cross-sectional view of a pixel structure according to an embodiment of the present invention, and Figure 1B for Figure 1A An exemplary top view diagram of , where Figure 1A corresponds to Figure 1B The I-I' line. Please also refer to Figure 1A and Figure 1B The pixel structure 100 is disposed on a substrate 102 and includes a data line DL, a scan line SL, an active device T, a pixel electrode 110 , a first common electrode 120 and a second common electrode 130 . The material of the substrate 102 can be glass, quartz, organic polymer, or opaque / reflective material or other applicable materials, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com