A portable cable binding fixture

A fixed and portable technology, applied in cable laying equipment and other directions, can solve the problems of increased maintenance costs, inconvenient use, and low operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

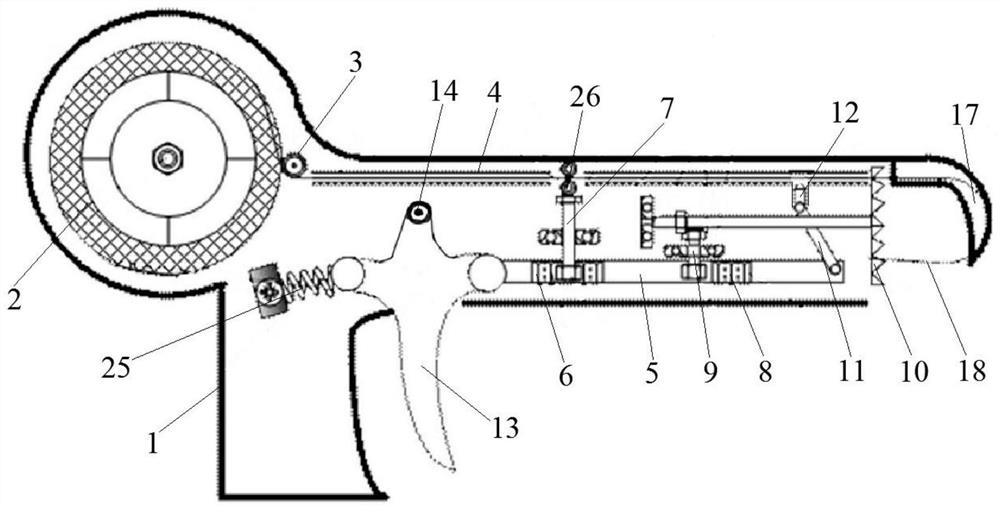

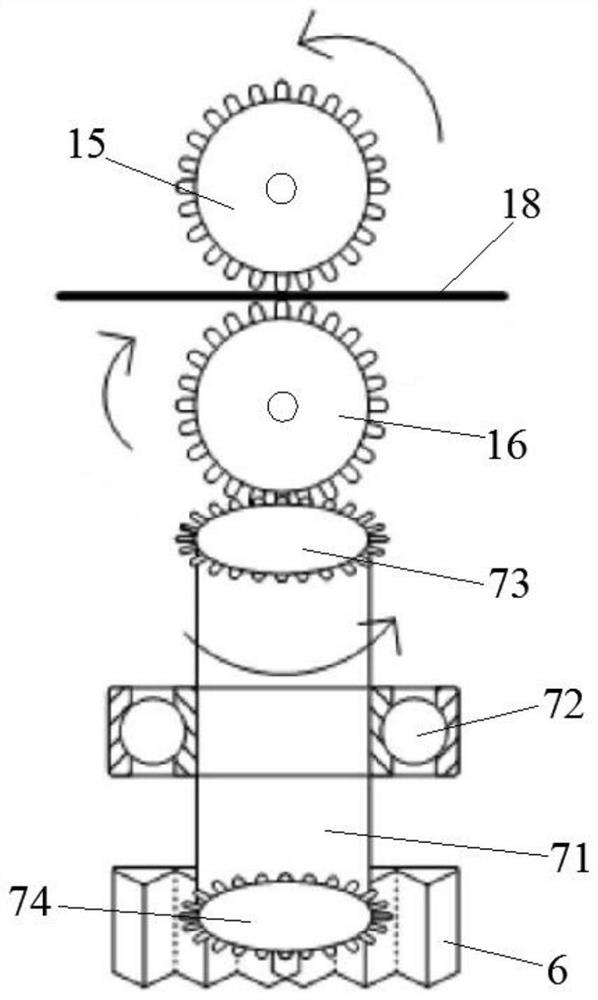

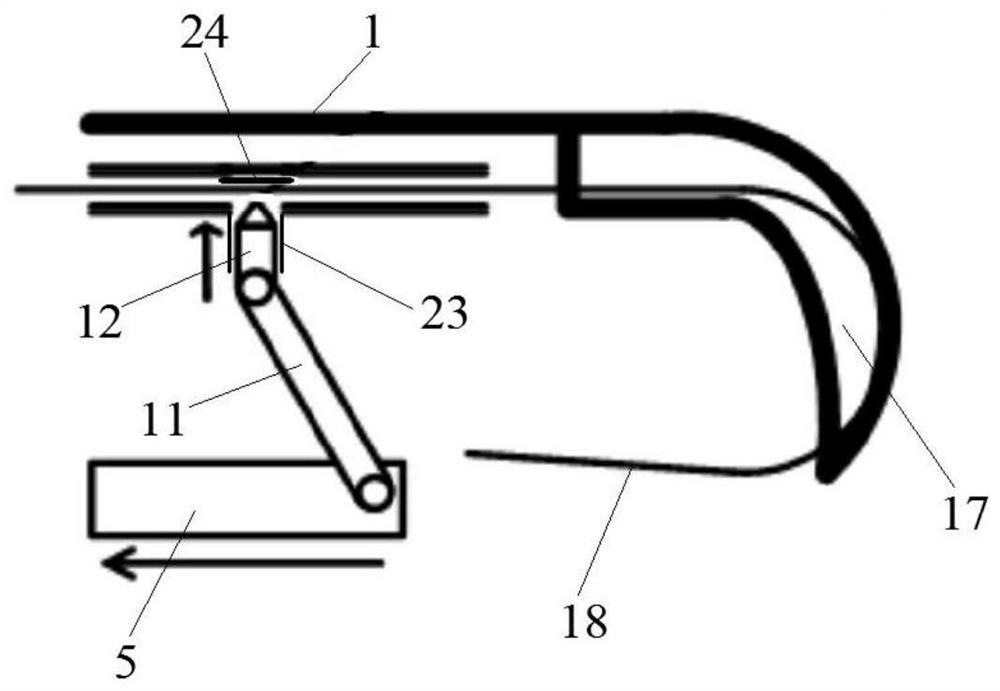

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] As shown in the accompanying drawings, a portable cable binding fixture includes a housing 1 in which a wire transmission channel 4, a trigger 13 and a wire tray 2 for winding iron wire 18 are installed, and the iron wire transmission channel 4 and the wire binding disc 2 are provided with a guide wheel 3 of a guide wire 10. The front side of the trigger 13 is connected with a transmission rod 5 that can slide back and forth. The trigger 13 is installed in the housing 1 through a rotating shaft 14. The trigger 13 The rear side is connected with the housing 1 via a spring 25 . The front end of the wire transmission channel 4 is provided with an arc-shaped fixed hook 17, and the inner surface of the fixed hook 17 is provided with a guide groove. The binding disc 10 is provided with a circular array of two rings of hollowed out slots 22 , and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com