Fixed jig for repairing electronic equipment

A technology for fixing fixtures and electronic equipment. It is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components. Light intensity, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

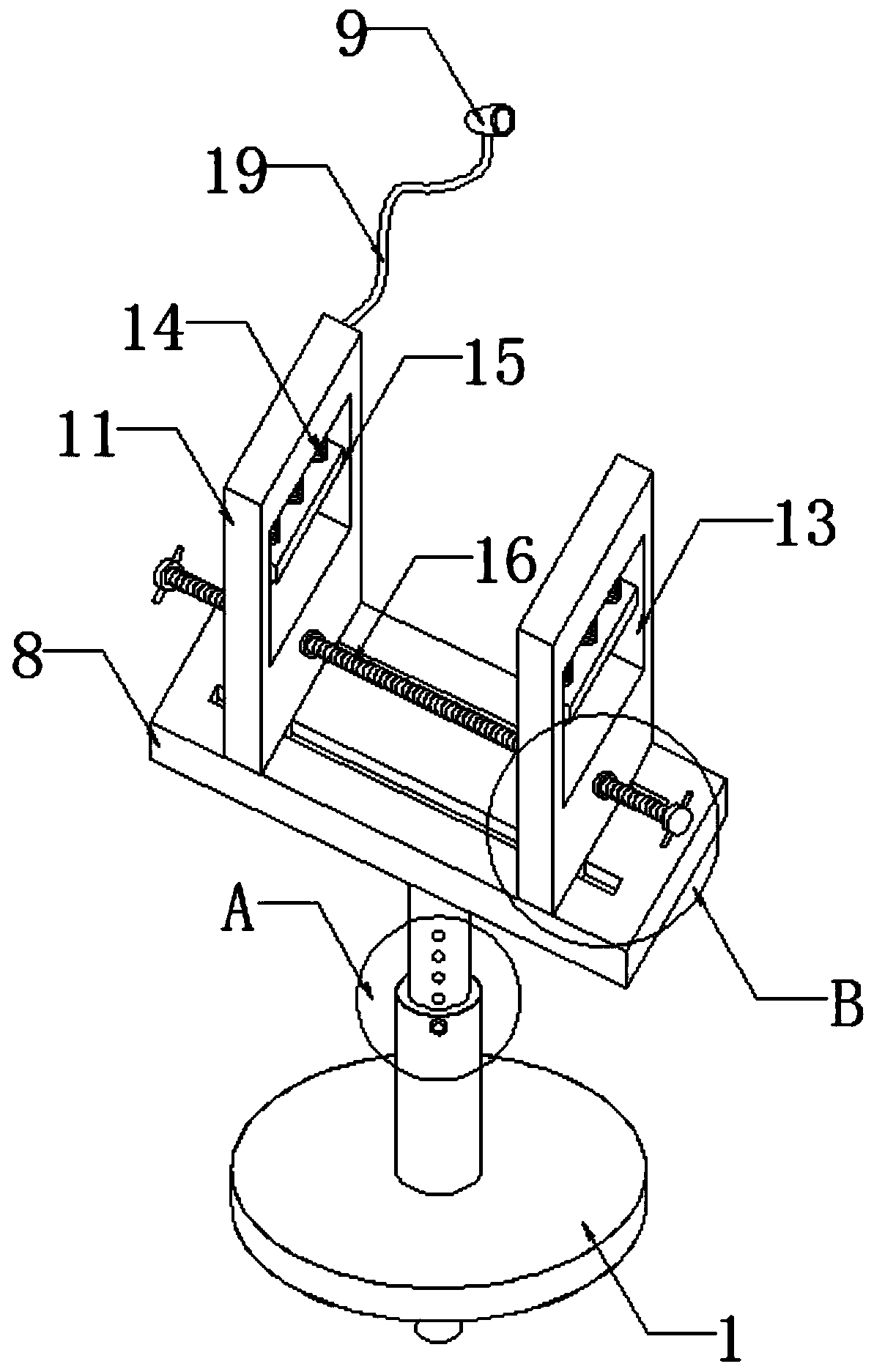

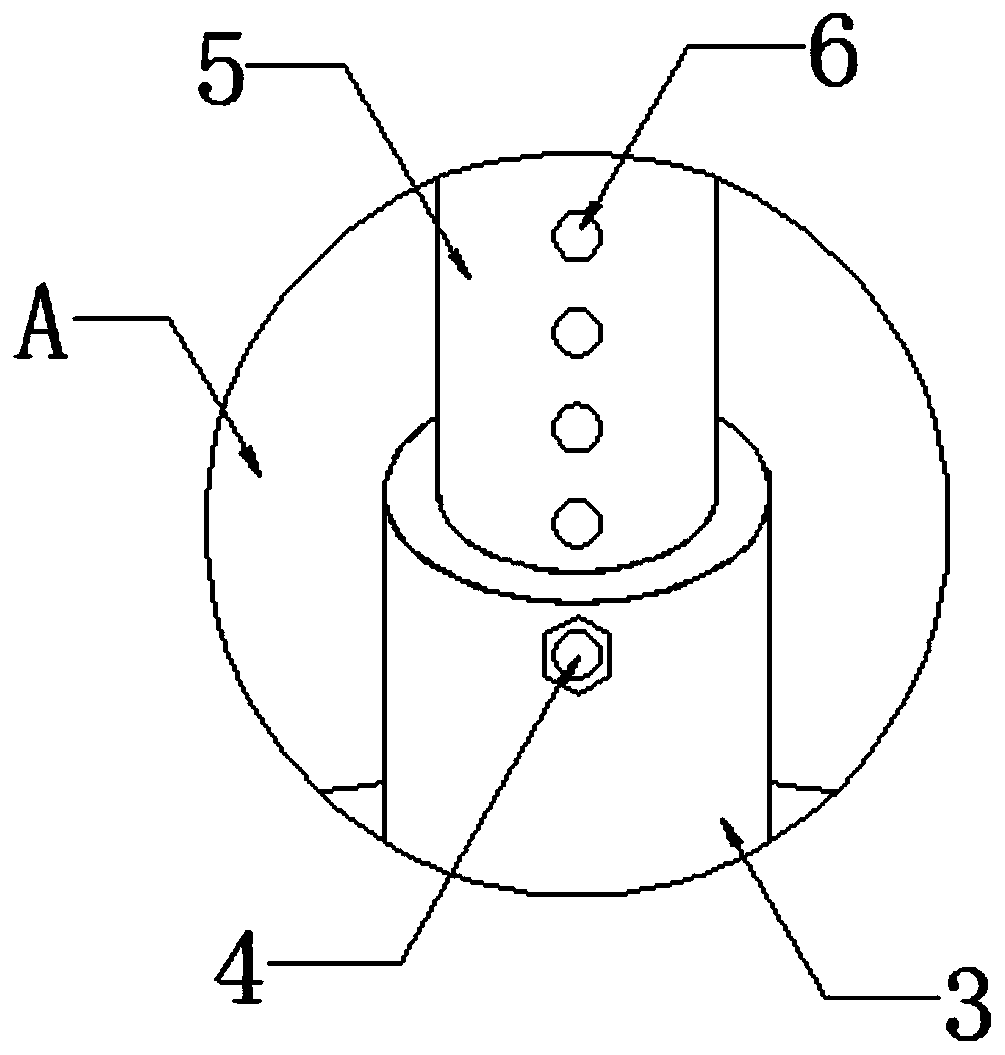

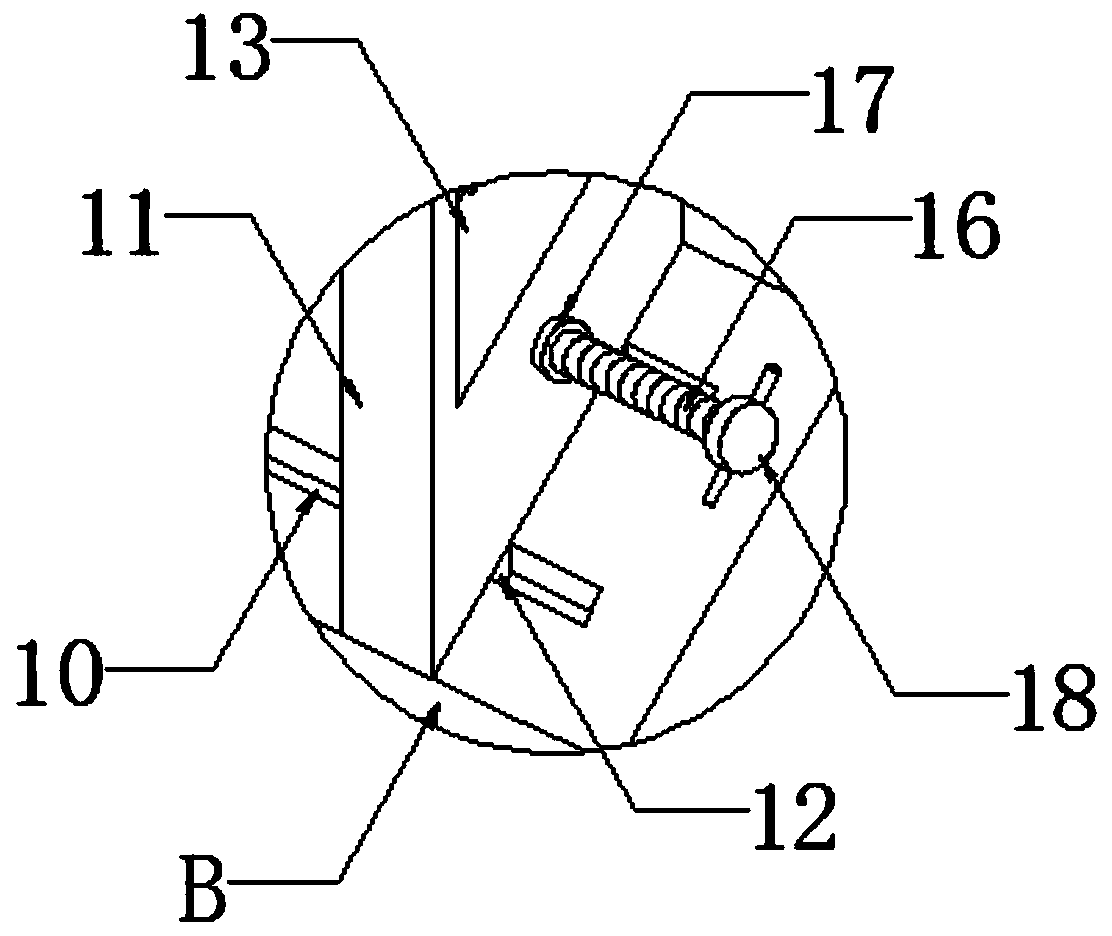

[0023] see Figure 1-4 , the present invention provides the following technical solutions: comprising a chassis 1 and a fixed platform 8, the middle part of the top of the chassis 1 is fixed with a support sleeve 3, the inside of the support sleeve 3 is slidably connected to a support column 5, and the top of the support column 5 passes through a bearing 7 It is rotatably connected with the middle part of the bottom end of the fixed table 8, which is convenient to adjust the rotation direction of the electronic equipment, and is convenient for the repair of the staff. The top of the fixed table 8 is provided with two chute 10, and the two chute 10 are connected to the connecting plate through the slider 12. 11 sliding connection, used to play a guiding role for the movement of the connecting plate 11, the tops of the two connecting plates 11 are provided with fixing grooves 13, and the tops of the two fixing grooves 13 are fixed with a pressure plate 15 through a compression sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com