Lubricant composition, method for producing lubricant composition, and continuously variable transmission

A lubricating oil composition and composition technology, applied in the direction of lubricating compositions, petroleum industry, transmission devices, etc., can solve the problems that are difficult to balance, and achieve the effects of high flash point, excellent low-temperature fluidity, and high traction coefficient

Active Publication Date: 2020-04-17

IDEMITSU KOSAN CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] For lubricating oil compositions used in traction-driven transmissions, from the viewpoint of ensuring high torque transmission capability, high temperature conditions are required (for example, if For automotive applications, a high traction coefficient of about 120°C is required. At the same time, in order to ensure low-temperature startability in cold regions such as North America and Northern Europe, low viscosity is required even at low temperatures (for example, about -40°C). Low temperature fluidity, but these properties are opposite properties, so it is difficult to balance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0079] Next, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0080] The properties and performance of the lubricating oil composition were measured by the following methods.

[0081] (1) Kinematic viscosity

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Login to View More

Abstract

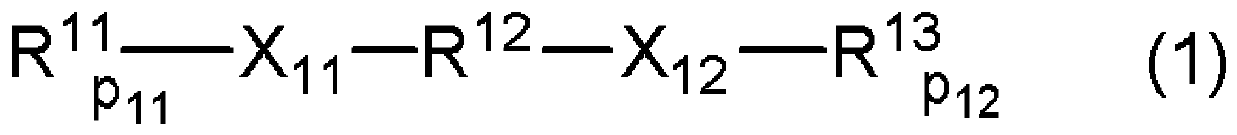

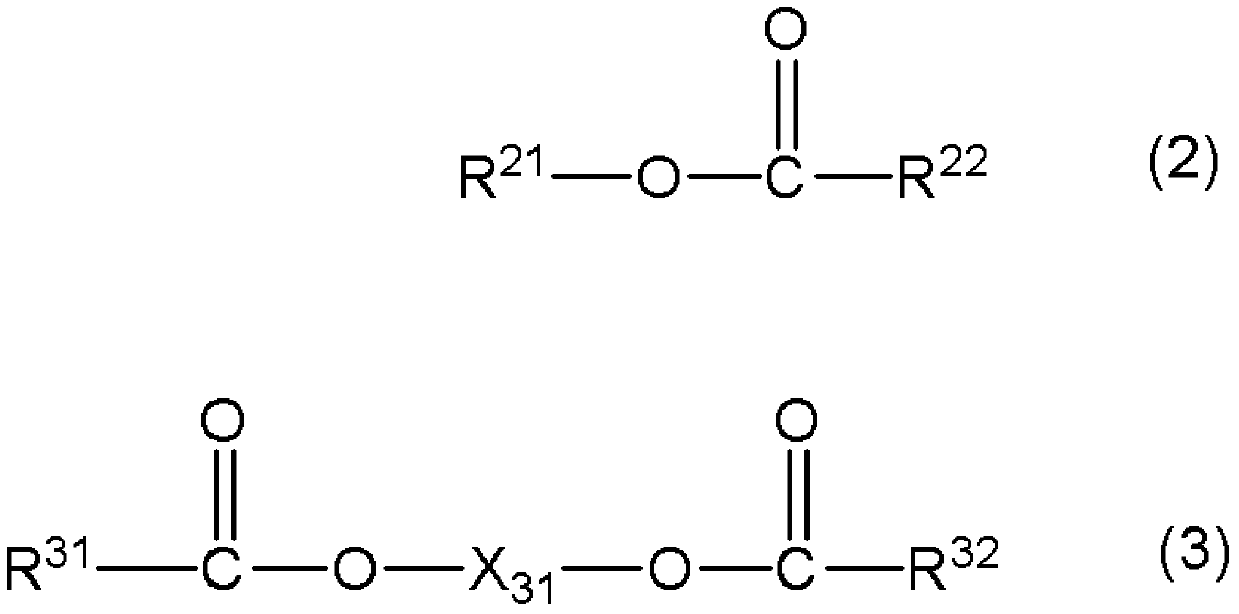

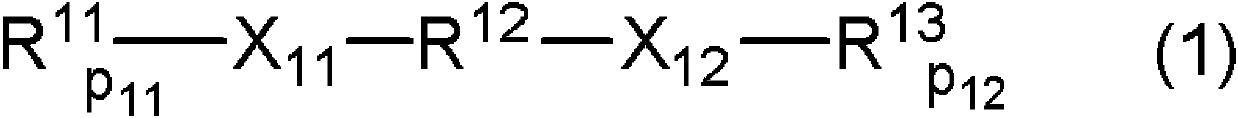

Provided are: a lubricant composition which has a good balance between a high traction coefficient and excellent fluidity at low temperatures at high levels, while having a high flash point, and whichcontains (a) a naphthenic synthetic oil having a flash point of 140 DEG C or higher and (b) an ester having a branched chain and 5-32 carbon atoms so that the content of the naphthenic synthetic oil(a) is 35% by mass or more but less than 80% by mass based on the total amount of the composition; a method for producing this lubricant composition; and a continuously variable transmission which uses this lubricant composition.

Description

technical field [0001] The present invention relates to a lubricating oil composition, a method for producing the lubricating oil composition, and a continuously variable transmission. Background technique [0002] Continuously variable transmissions, especially traction drive transmissions, are smaller and lighter than transmissions using gears, and can change gears without metal-to-metal contact, so they are less likely to generate noise. Therefore, traction-driven transmissions are being studied especially for applications centered on electric vehicles. [0003] For lubricating oil compositions used in traction-driven transmissions, a high traction coefficient is required under high temperature conditions (for example, about 120° C. for automotive applications) from the viewpoint of securing a large torque transmission capability, and at the same time , in order to ensure low-temperature startability in cold regions such as North America and Northern Europe, low-temperat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M111/02F16H15/00C10M105/04C10M105/32C10M105/34C10M105/38C10N20/00C10N20/02C10N30/02C10N30/06C10N40/04

CPCC10M169/04F16H15/00C10M111/02C10N2040/045C10N2030/74C10N2020/071C10N2030/02C10N2030/06C10M2203/045C10M2207/283C10M2207/2835C10M2207/2815C10M2207/2825C10M105/04C10M105/34C10M105/38C10M2203/04C10M2203/065C10M2207/2805C10N2040/04

Inventor 砂川洋二岩崎猛

Owner IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com