Liquid jet shaper and spray shaper

A technology of shaper and spray distributor, which is applied in the direction of spraying device, spraying device, indoor sanitary pipeline device, etc., can solve the problems of electric danger, difficult installation, maintenance and repair of jet flow shaper, and achieve low consumption and cheap production And the effect of simple and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

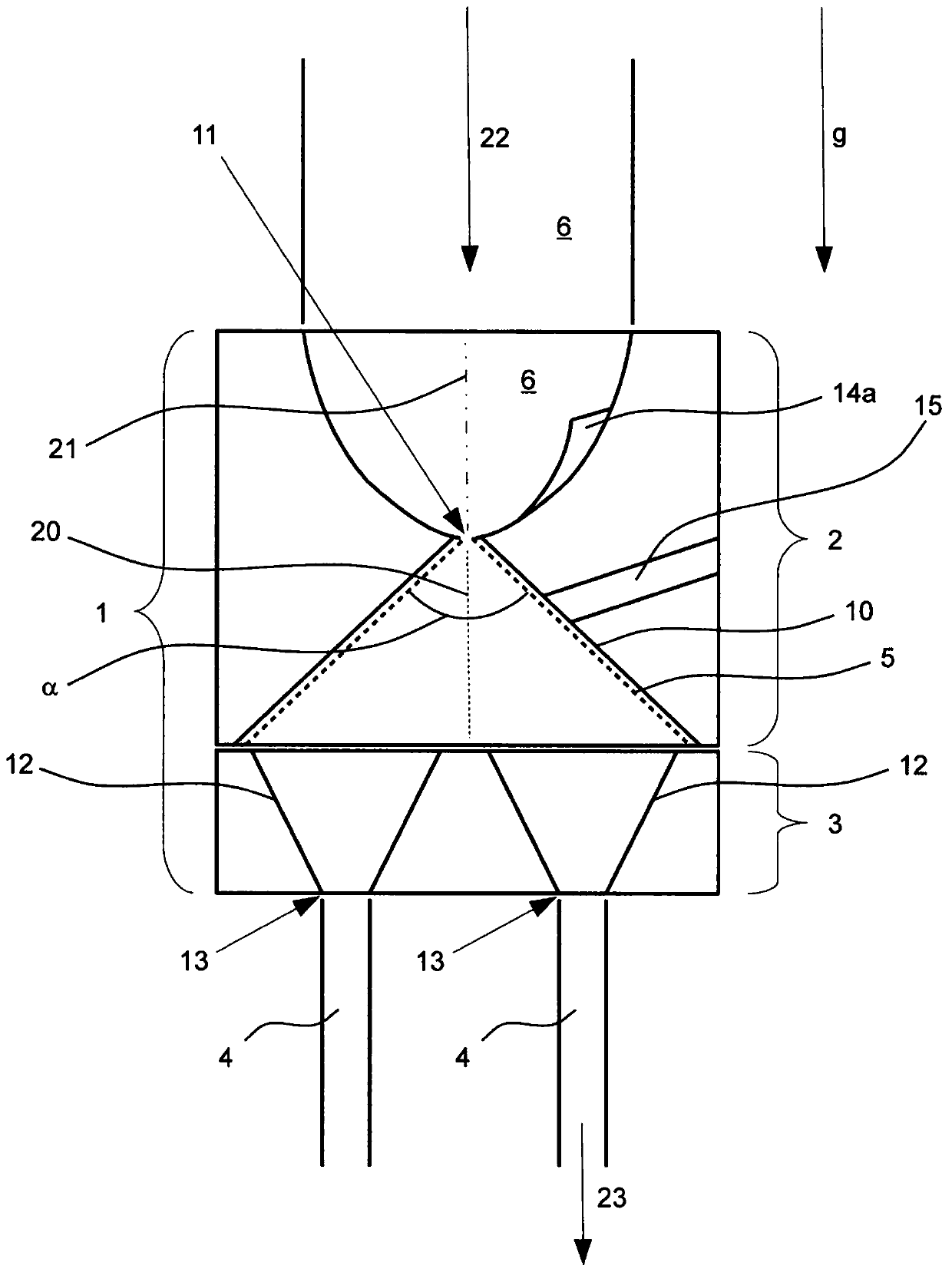

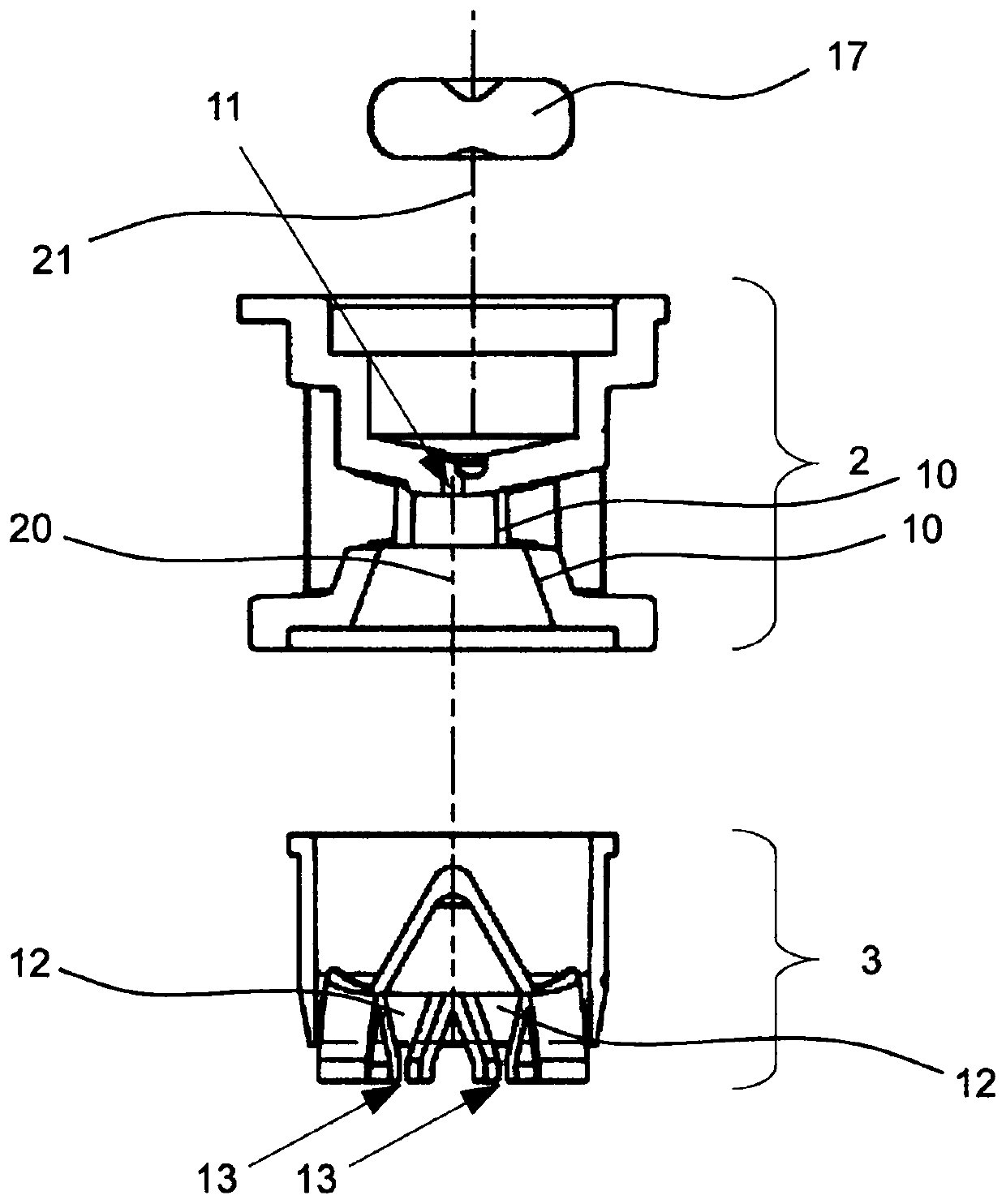

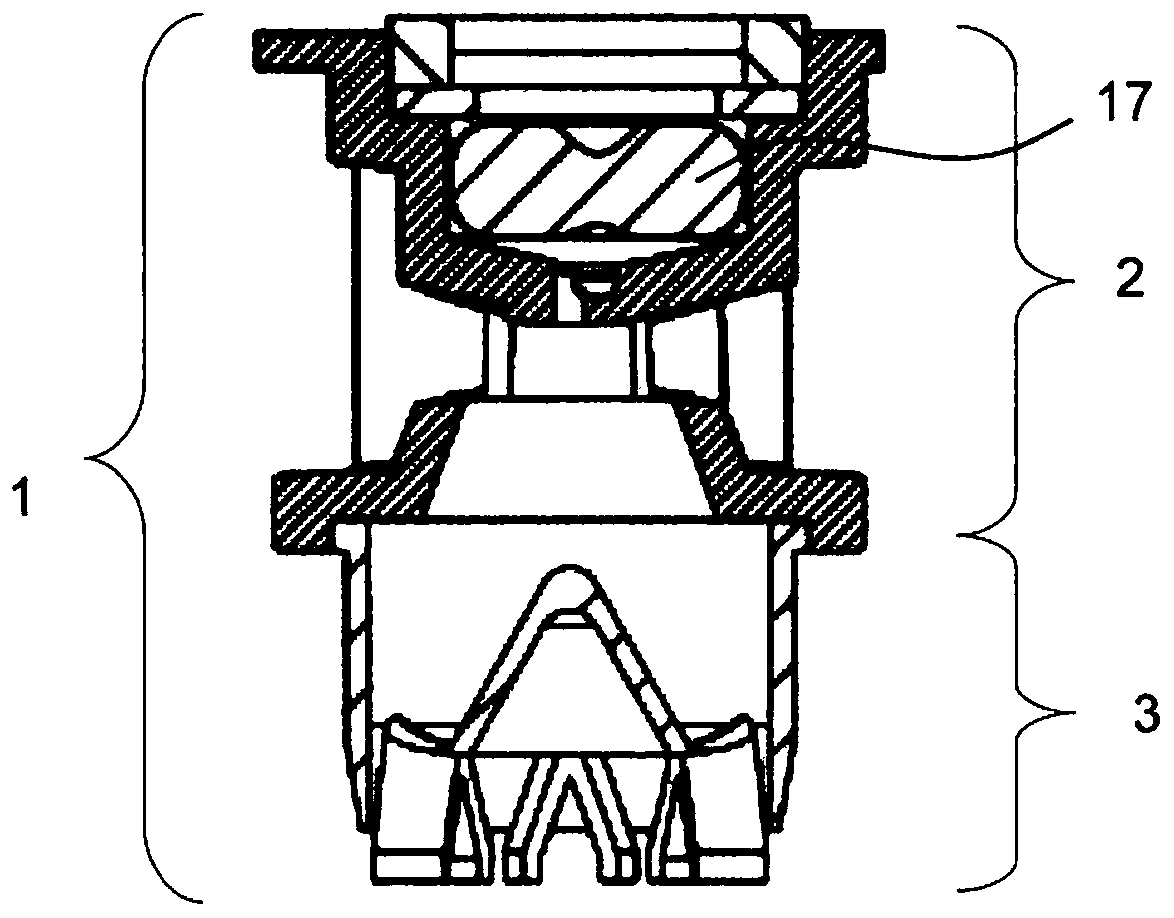

[0206] figure 1 A schematic overview of a section through an example of an embodiment of the jet shaper 1 is shown in side view. Gravity direction g from figure 1 the top of the (i.e. figure 1 the top edge of the drawing plane) extends to figure 1 the bottom of the (i.e. figure 1 bottom edge of the drawing plane). The jet shaper 1 comprises a spray generator 2 arranged at the top of the jet shaper 1 and a spray distributor 3 arranged at the bottom of the jet shaper 1 . The liquid 6 flows into the jet shaper 1 in a liquid inflow direction 22 parallel to the direction of gravity g.

[0207] The liquid 6 flows into the spray generator 2 and into the guide element 14 a arranged in the spray generator 2 . The guide element 14 a produces a rotational movement of the liquid 6 about the swivel axis 21 . Due to the rotational movement of the liquid 6, the liquid 6 is dispersed into spray droplets at the outlet 11 of the spray generator. The spray droplets expand into a spray co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com