Cathode assembly having a dual position magnetron and centrally fed coolant

A magnetron and coolant technology, applied in the field of magnetron, can solve the problems of laborious chamber, changing power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

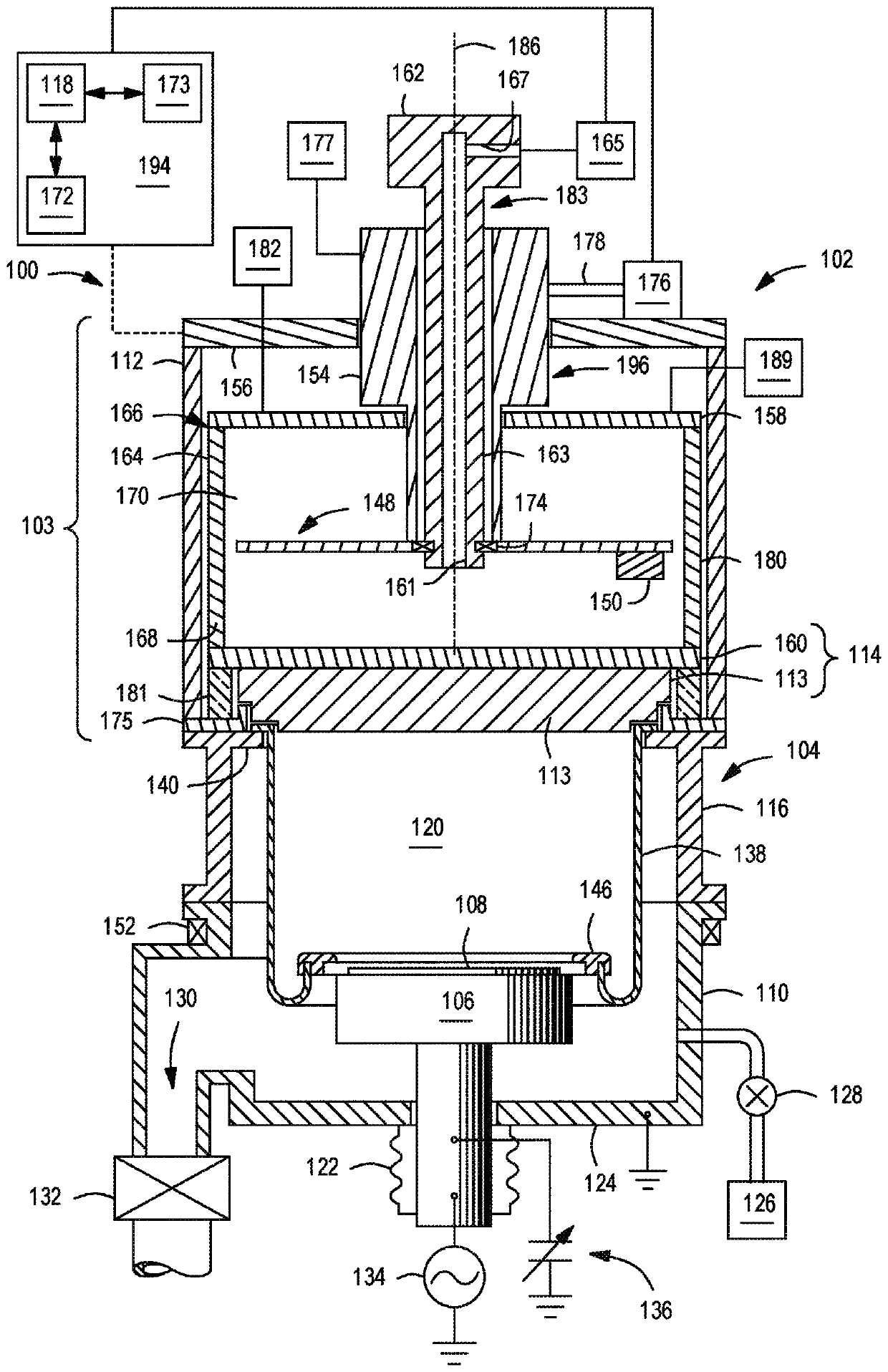

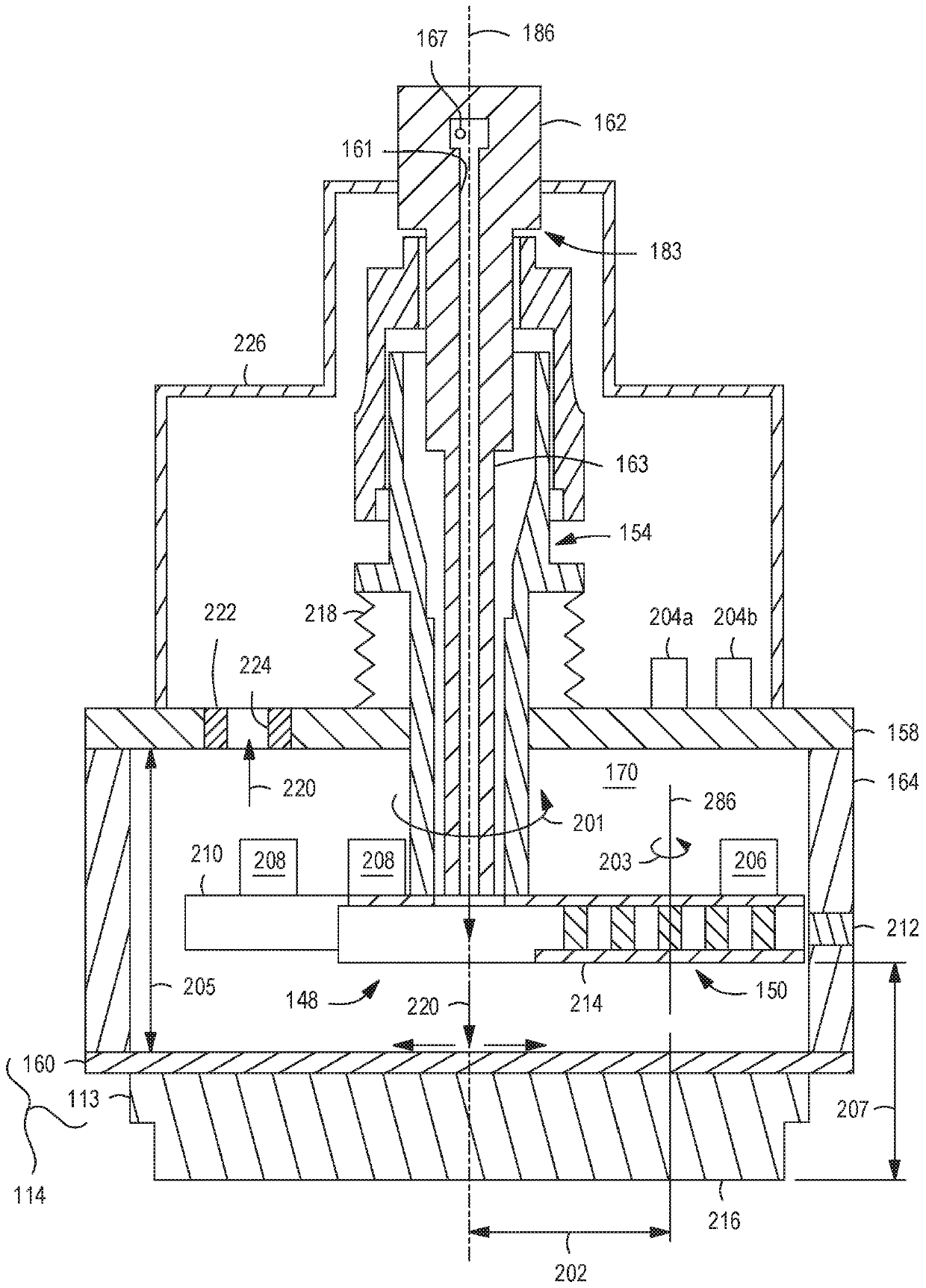

[0015] The present disclosure relates to a cathode assembly having a two-position magnetron that can advantageously utilize a centralized supply of coolant for improved cooling and that can be achieved by both in the deposition process and in the physical The distance between the lowermost surface of the magnet of the magnetron and the lowermost surface of the sputtering target is kept constant during the vapor deposition (PVD) chamber to ensure a constant deposition rate. The magnetron of the present invention advantageously mitigates cracking and / or bowing of the target due to overheating and decreases in deposition rate over the lifetime of the target.

[0016] Embodiments of the magnetron disclosed herein have two positions (an outer radial position and an inner radial position) so that the magnetic field at the sputter target surface can be changed by reconfiguring the magnetic poles at different positions. Therefore, since both the center and the periphery of the target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com