Aluminum material cutting device with automatic feeding function

A technology for automatic feeding and cutting devices, applied in the direction of shearing devices, attachments of shearing machines, maintenance and safety accessories, etc., to achieve the effect of avoiding poor air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

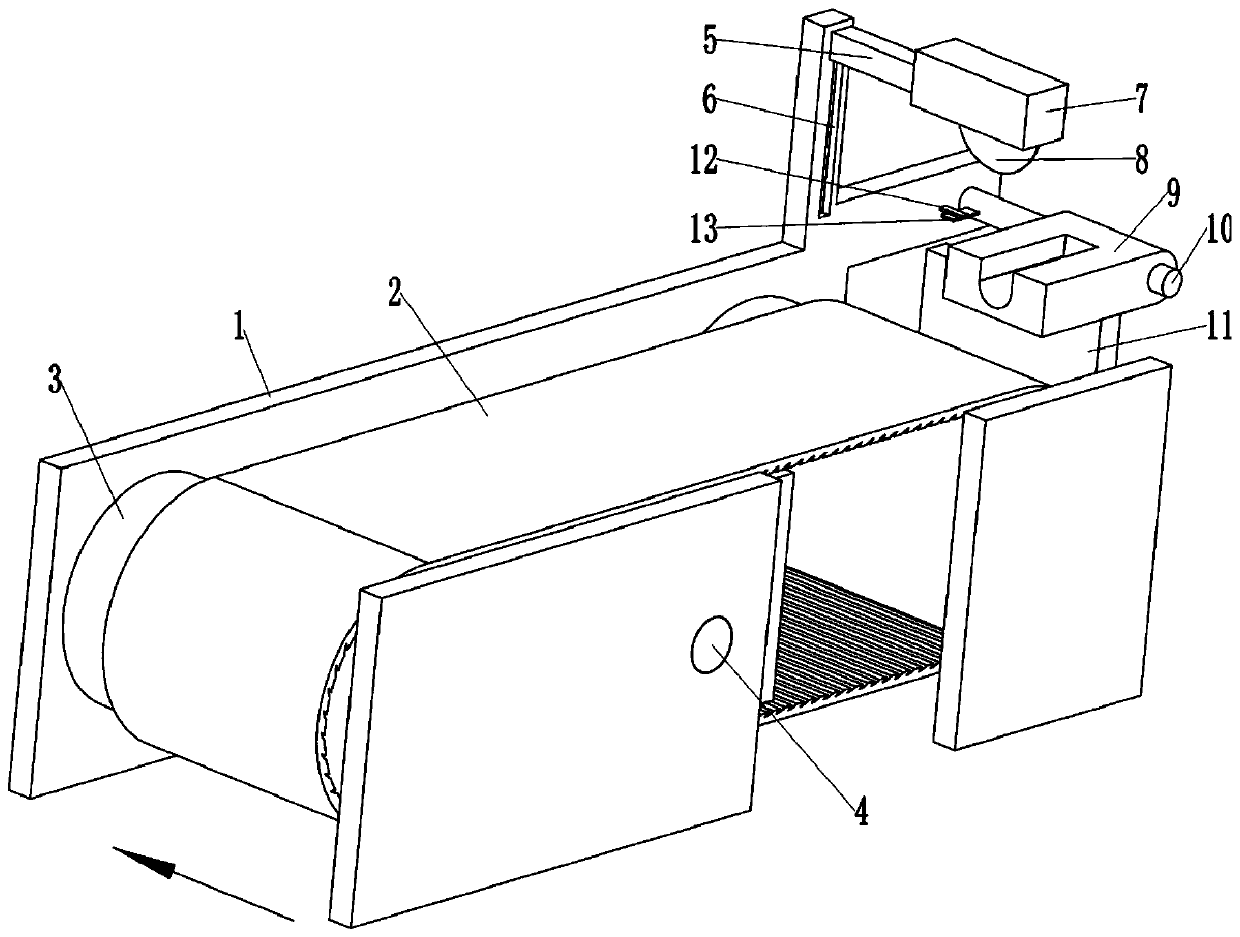

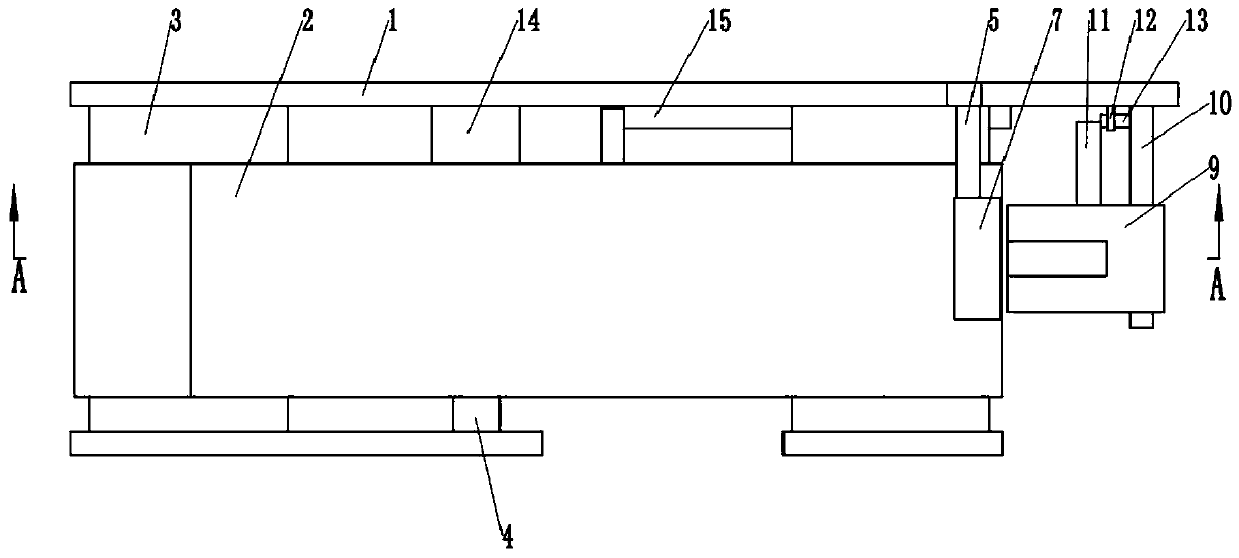

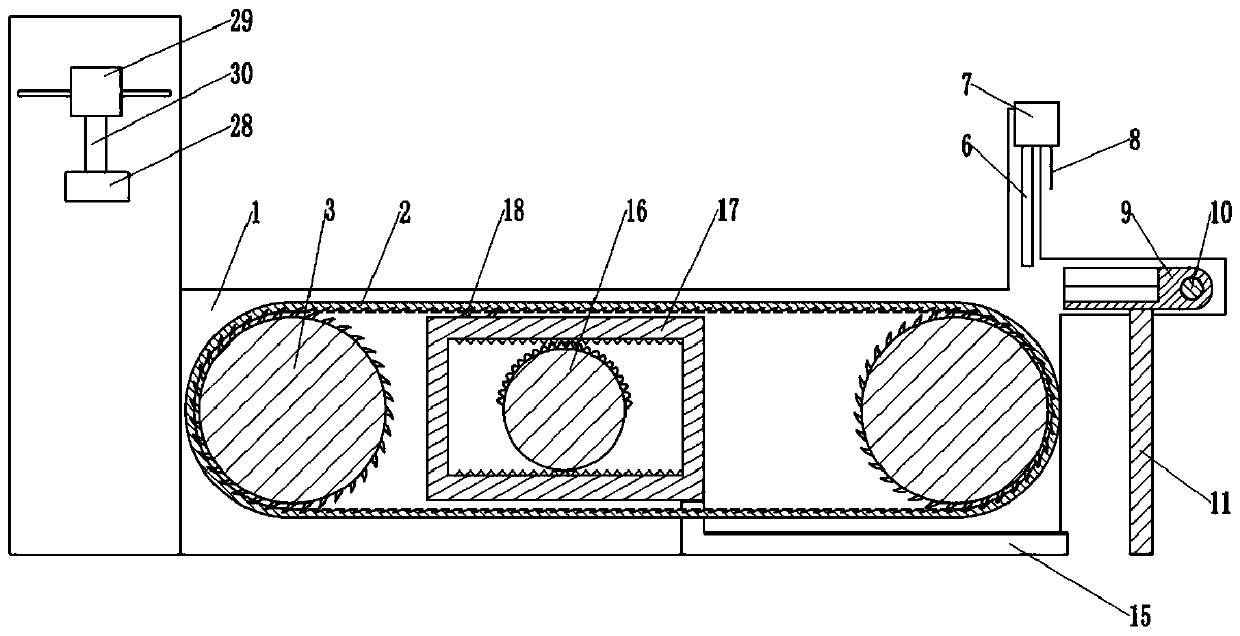

[0033] as attached figure 1 Shown: an automatic feeding aluminum material cutting device, including a frame 1 and a feeding unit, the feeding unit includes a conveyor belt 2 and a driving structure for driving the conveyor belt 2, and the conveyor belt 2 is stretched directly on the frame 1, specifically as image 3 As shown, there are two cross bars 3 clamped and fixedly connected to the frame 1 , the longitudinal section of the cross bars 3 is circular, and the conveyor belt 2 is stretched straight on the two cross bars 3 . Such as image 3 As shown, the driving structure is arranged in the conveyor belt 2, the driving structure includes a driving gear 16 and a rectangular frame 17, the rectangular frame 17 is horizontally slidably connected with the frame 1 through a chute, and the top and bottom of the inner peripheral surface of the rectangular frame 17 are clamped and fixed. There is a rack, and the driving gear 16 is an incomplete gear, and the driving gear 16 is meshe...

Embodiment 2

[0045] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the frame 1 is fixed with a seal box 19 by bolts, and a piston 20 is horizontally slid in the seal box 19, and the left end of the piston 20 is clamped and fixedly connected with a piston rod 21. The piston rod 21 is clamped and fixed with the rectangular frame 17 . The piston 20 separates the sealed box 19 into a first sealed space 26 and a second sealed space 27, the first sealed space 26 is communicated with a first hose 22, the second sealed space 27 is communicated with a second hose 23, and the second sealed space 27 is communicated with a second hose 23. The position where the flexible pipe 23 communicates with the sealed box 19 is located at the top of the sealed box 19; Figure 5 As shown, the support member 9 is provided with an air blow hole 24, and the upper end of the air blow hole 24 is inclined to the left, so that the airflow blown out by the air blow hole 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com