Full-automatic circular seam welder

A fully automatic, seam welding machine technology, applied in the welding of curved surface seams, roller electrode welding, welding equipment, etc., can solve the problems of process responsibility and low efficiency, and achieve the effect of reducing labor force, improving work efficiency, and increasing positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

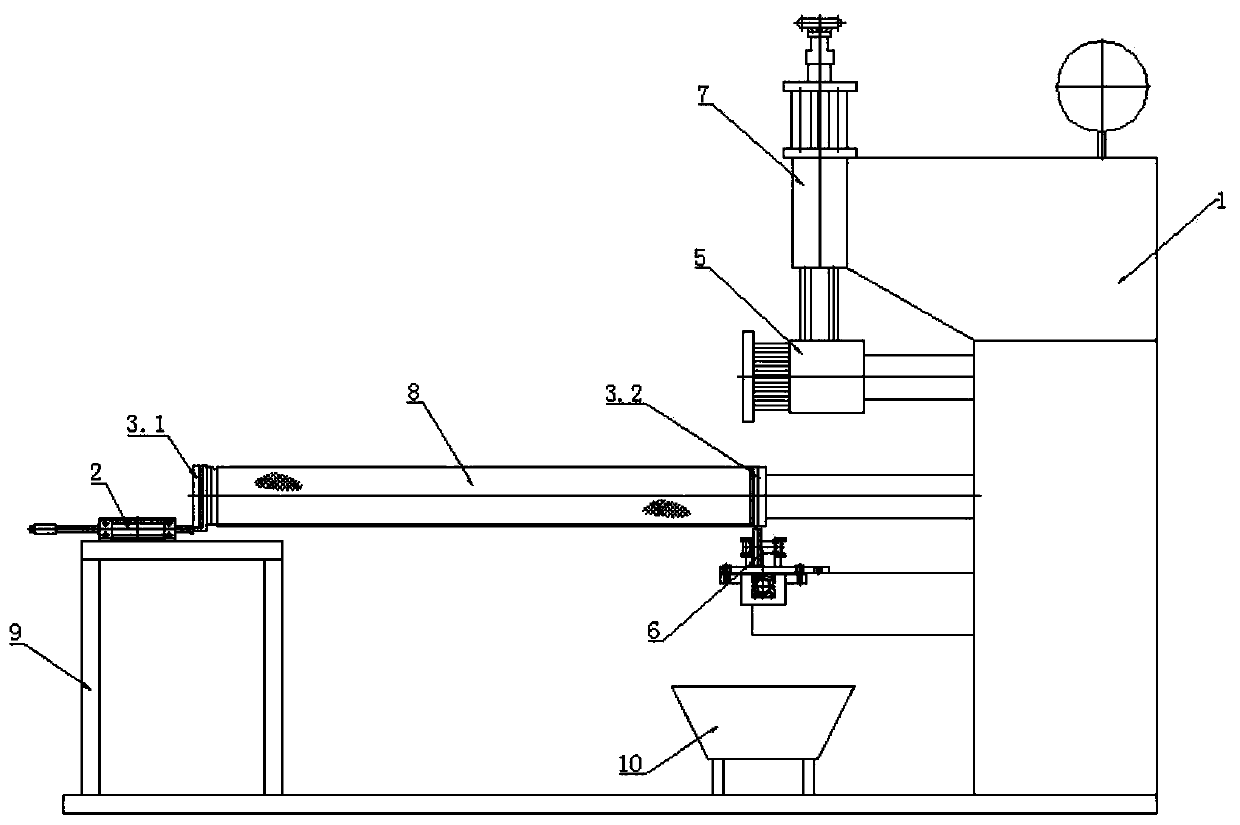

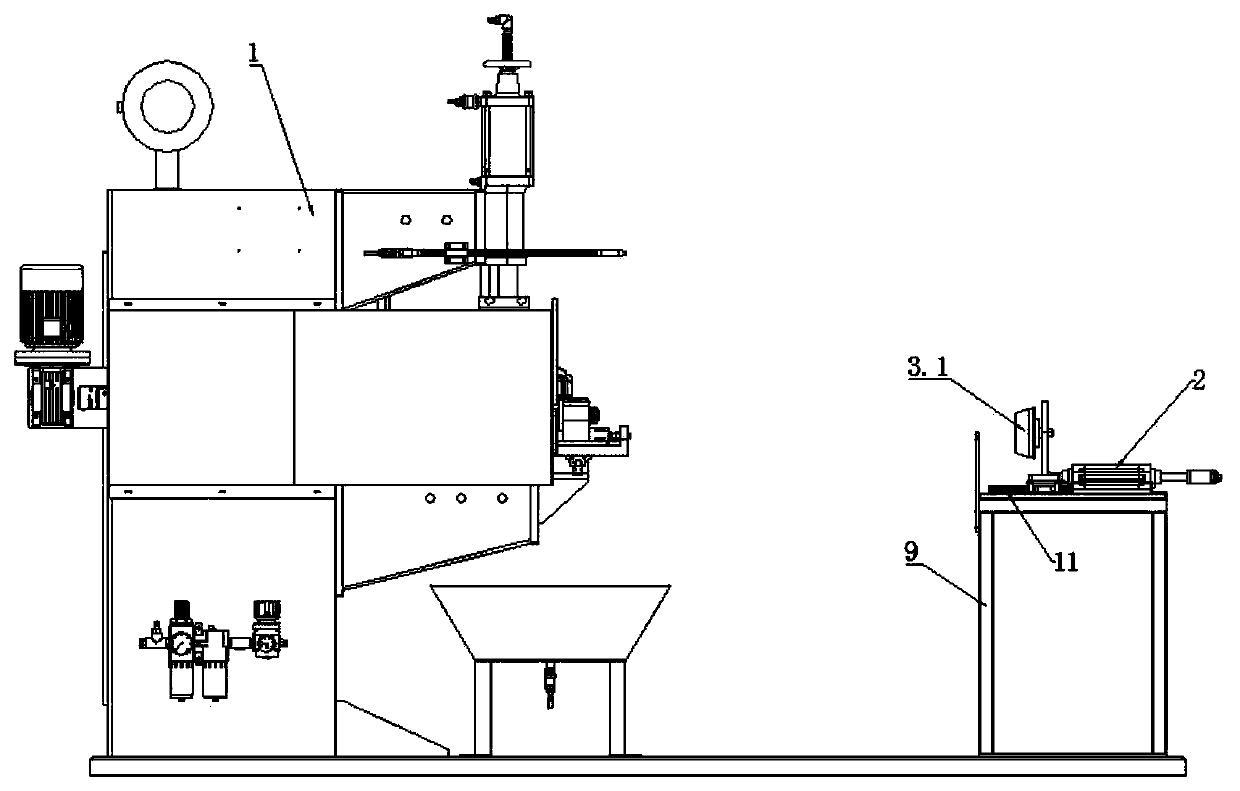

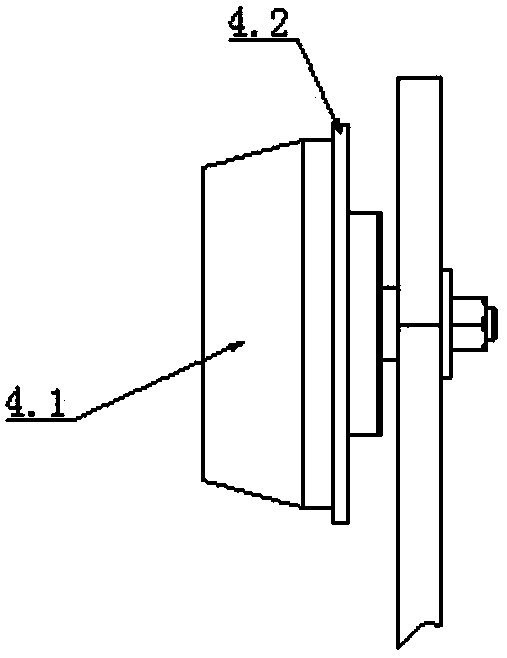

[0017] Embodiment one: by Figure 1 to Figure 3 Given, the fully automatic circular seam seam seam welding machine includes a machine body 1 and a seam welding device, the seam welding device includes an upper welding wheel 5 and a lower welding wheel 6, and the upper rolling welding wheel 5 moves up and down through the first cylinder 7 , the side of the body 1 away from the seam welding device is provided with a bracket 9, the body 1 is provided with a positioning device, the positioning device includes a fixed shaft 3.2 and a clamping shaft 3.1 at the same height, the clamping The shaft 3.1 is located on the bracket 9 and is slidingly connected with it, the parts 8 to be welded are located between the fixed shaft 3.2 and the clamping shaft 3.1, the upper welding wheel 5 is located above the fixed shaft 3.2, and the lower welding wheel is located on the fixed shaft 3.2 Below, before placing the parts, adjust the upper roll welding wheel 5 and move it away from the fixed shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com